SsangYong Rexton. Manual - part 395

DIESEL ENGINE MECHANICAL 1B3-155

SSANGYONG Y200

YAD1B3Z0

YAD1B4B0

YAD1BK80

Tools Required

102 589 00 15 00

Drift

102 589 12 15 00

Drift

Replacement Procedure

1. Completely drain the coolant.

2. Remove any parts which impede access.

(Example : transmission, injection pump)

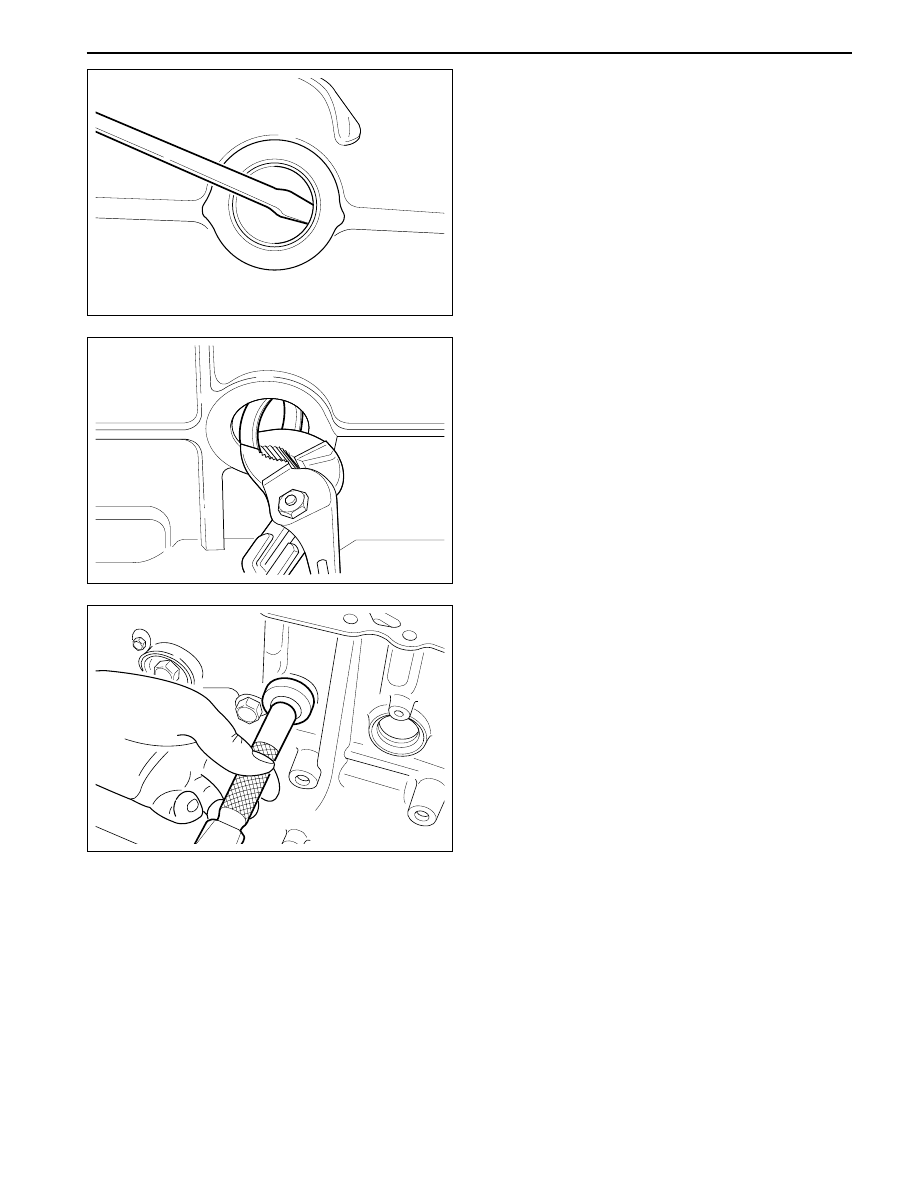

3. Place the screwdriver to the deepdrawn edge of

the core plug and pull forward and then rotate 90°.

5. Thoroughly clean the sealing surface and apply

Loctite 241.

6. Install the new core plug by using a drift.

7. Install the removed parts and fill the coolant.

Notice: The adhesive must be allowed to harden

for about 45 minutes before filling of coolant.

8. Warm up the engine and check the coolant for

leaks.

4. Pull out the core plug with pliers.