SsangYong Rexton. Manual - part 340

M161 ENGINE MECHANICAL 1B2-43

SSANGYONG Y200

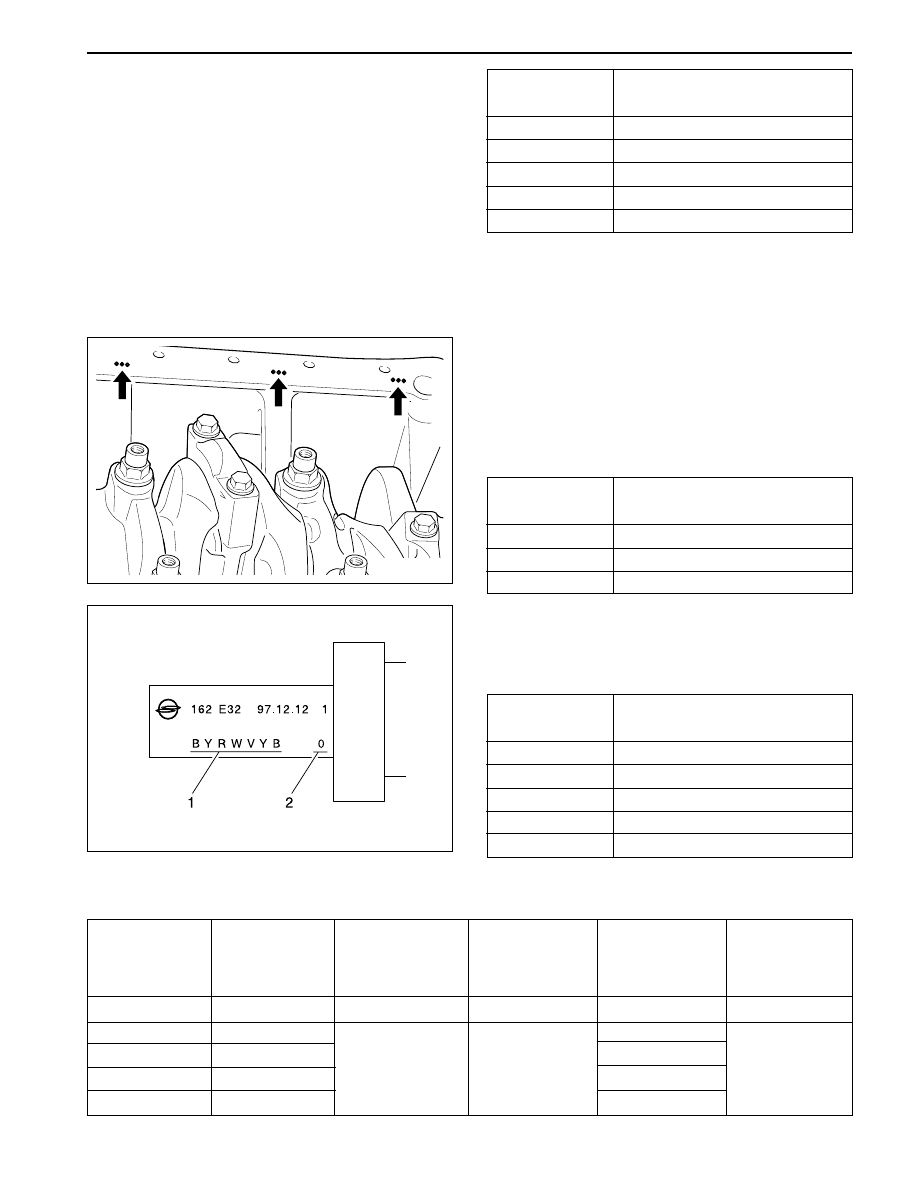

Selection of Crankshaft Main Bearing

1. Crankcase Side

There are seven punching marks on the mating

surface to oil pan. This mark is correspondent to

the bearing distinguished by color. Select the

relevant bearing according to the punching mark

when repaired.

2. Crankshaft Bearing Cap Side

Select the crankshaft main bearing according to

the marking letter on the crank shaft main journal

when repaired.

YAD1B880

YAD1B890

Service Data

Crankshaft

Standard and

Repair Size

Standard size

1st repair size

2nd repair size

3rd repair size

4th repair size

Crankshaft

Bearing Jour-

nal Diameter

57.940 - 57.965

57.705 - 57.715

57.450 - 57.465

57.205 - 57.215

56.955 - 56.965

Crankshaft

Bearing

Diameter

58

-

Crankshaft

Journal Width

at fit bearing

24.50 - 24.533

-

Connecting Rod

Bearing Journal

Diameter

47.935 - 47.965

47.700 - 47.715

47.450 - 47.465

47.200 - 4.215

46.950 - 46.965

Connecting Rod

Bearing Journal

Width

27.958 - 28.042

-

Color Dot

Marking

Blue

Yellow

Red

White

Violet

Crankshaft Journal Diameter

(mm)

57.960 - 57.965

57.955 - 57.960

57.950 - 57.955

57.945 - 57.950

57.940 - 57.945

Purching

Mark

B

Y

R

Bearing Color Selected

Blue

Yellow

Red

Marking

Letter

B

Y

R

W

V

Bearing Color Selected

Blue

Yellow

Red

White

Violet