SsangYong Rexton. Manual - part 50

DI04-13

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

EXHAUST SYSTEM

DI ENG SM - 2004.4

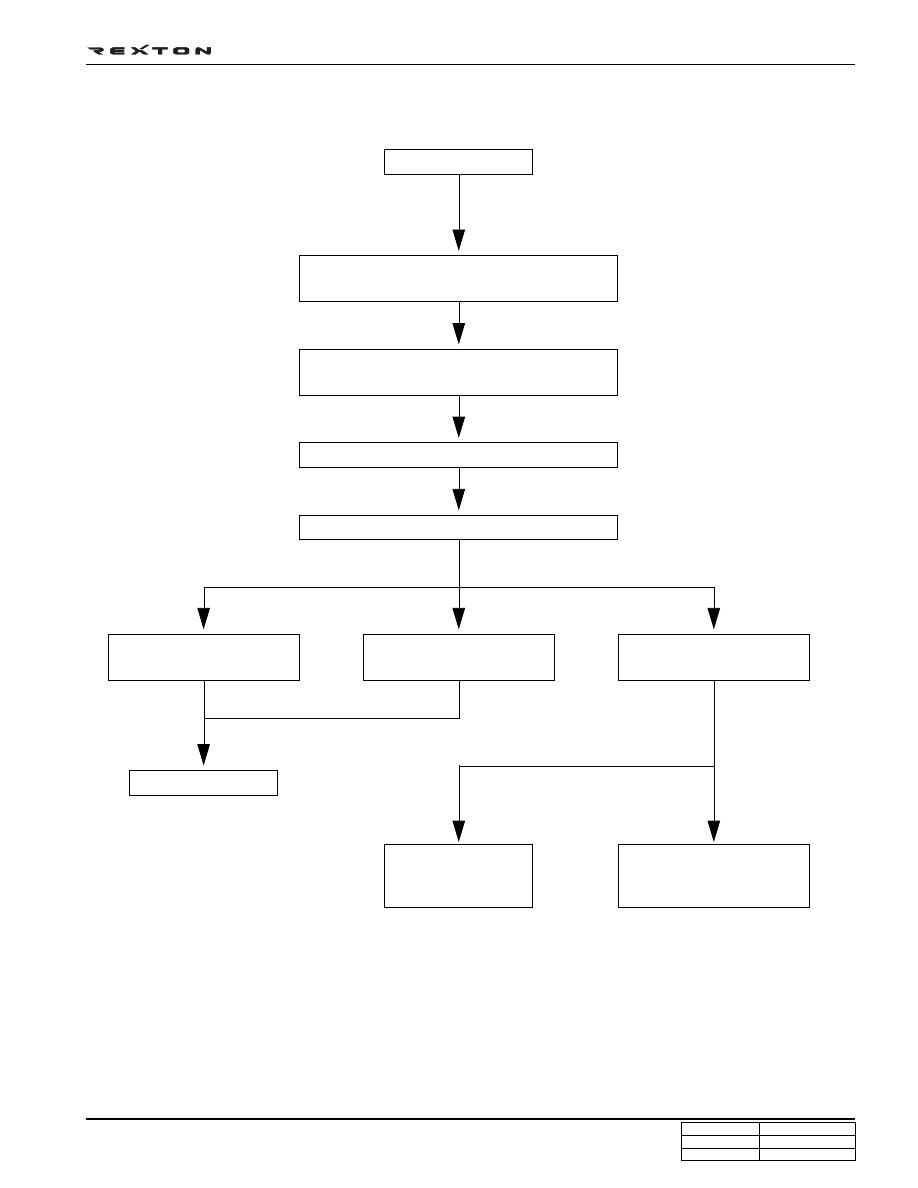

2. Oil Pump Defect: Rapid over-loaded driving after replacing oil filter and oil and clogging of oil

line.

Poor Oil Supply

Metal Contact of Shaft /Journal Bearing/

Center Housing Inner Part

Journal Bearing/Center Housing Inner Part

Wear/Seizure

Seal Wear at Exhaust

System

Interference of Turbine and

Compressor Components

Oil Leakage

Seal Wear at Intake

System

Abnormal Noise

Melt down of Bearing to Turbine Wheel Journal

Rotor Rotational Movement

Lack of Power/Poor

Acceleration (Lack of

Turbo Charged Pressure)