SsangYong Stavic / SsangYong Rodius (2005 year). Manual - part 353

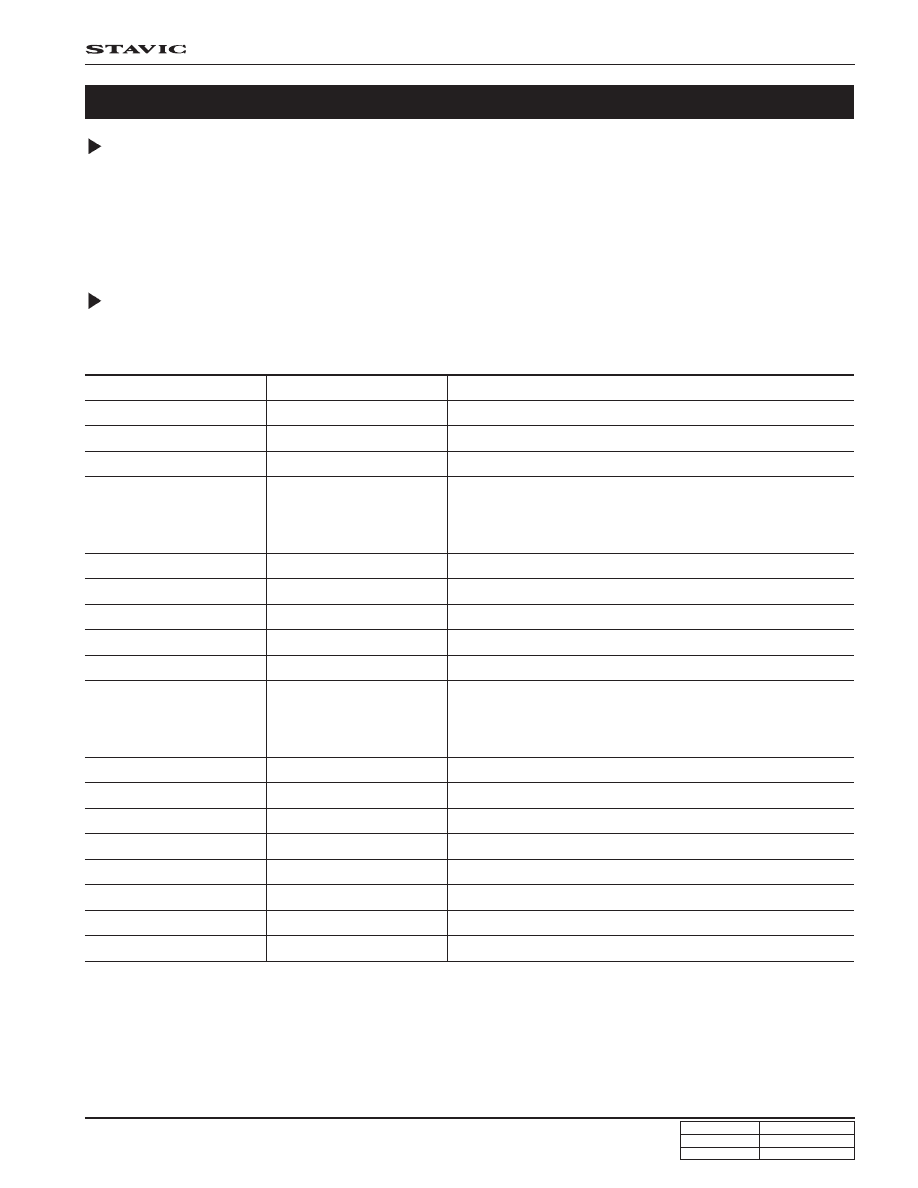

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

19

TOD

STAVIC - 2004.09

4D

4H/4L Switch Input

4H

4H

4H

4H

4H

4H

4H

4H

4H

4L

4L

4L

4L

4L

4L

4L

4L

4L

Motor Position

Left stop

Left top

Top

Right top

Zone 1

Neutral

Zone 2

Bottom

Right stop

Left stop

Left top

Top

Right top

Zone 1

Neutral

Zone 2

Bottom

Right stop

Operation

Does not operate, 4L lamp off

Does not operate, 4L lamp off

Does not operate, 4L lamp off

- 4L lamp flickers

- Tries shifting to 4H if shifting conditions are satisfied.

- After shifting to 4H the flickering of 4L lamp stops.

Same as above

Same as above

Same as above

Same as above

Same as above

- 4L lamp flicker

- Tries shifting to 4L if shifting conditions are satisfied.

- After shifting to 4L the 4L lamp lights on.

Same as above

Same as above

Same as above

Same as above

Same as above

Same as above

Does not operate, 4L lamp lights on

Does not operate, 4L lamp lights on

TCCU Initialization

• TCCU sends relevant data to meter cluster via CAN to diagnose and check the indicators when the ignition switch is

turned to ON. At this time, the 4WD indicators (4WD LOW, 4WD HIGH, 4WD CHECK) comes on for 0.6 seconds.

• If the selector switch position and the shift motor position code does not match when the IG power is turned ON, the

shift is controlled to move in the direction of the selector switch position

Interpretation of Position Sensor

- When the 4H/4L switch is operated and the position sensor recognizes the shift motor position while the system is

energized, the system operates as follows:

SYSTEM OPERATION