SsangYong Korando II (1996-2006 year). Manual - part 250

ABS AND TCS 4F-15

SSANGYONG MY2002

DIAGNOSIS

KAA4F110

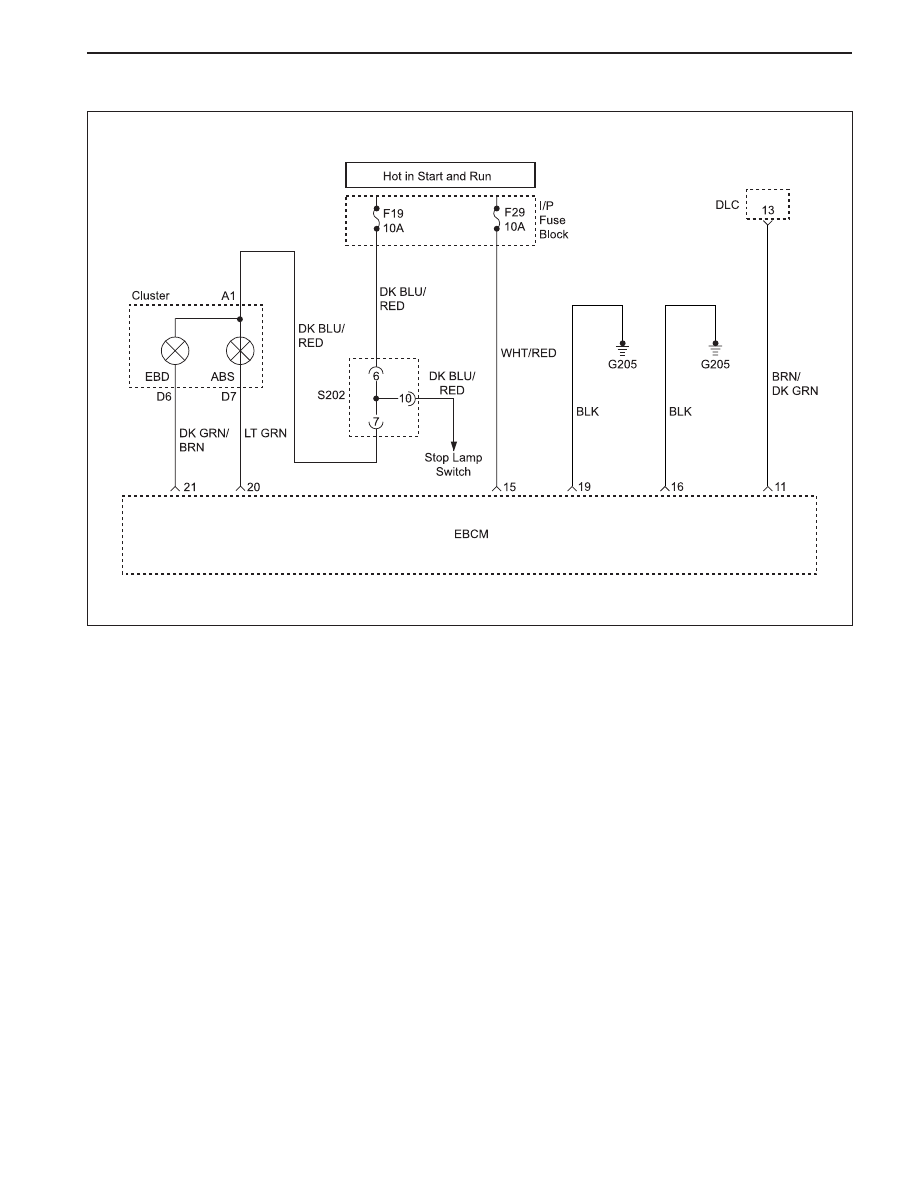

DIAGNOSTIC CIRCUIT CHECK

The Diagnostic Circuit Check is an organized approach

to identifying a problem created by an antilock brake

system (ABS) malfunction. If must be the starting point

for any ABS complaint diagnosis because it directs

the service technician to the next logical step in

diagnosing the complaint.

Diagnostic Process

Perform the following steps in order when servicing

the ABS/TCS system. Failure to do so may result in

the loss of important diagnostic data and may lead to

difficulties and time-consuming diagnosis procedures.

1. Perform the tests of the table below.

2. Perform a road test if directed by the table.

•

Test drive the vehicle while using the snapshot

feature of the scan tool.

•

Perform normal acceleration, stopping, and

turning maneuvers.

•

If this does not reproduce the malfunction,

perform an ABS stop or TCS maneuver on a low

friction surface such as gravel.

3. Clear the diagnostic trouble codes (DTCs) after

all system malfunctions have been corrected.