SsangYong Actyon Sports II. Manual - part 21

03-4

2. MAINTENANCE AND INSPECTION

1) Maintenance Procedures for DI Engine Fuel System

Always keep the workshop and lift clean (especially, from dust).

Always keep the tools clean (from oil or foreign materials).

Wear a clean vinyl apron to prevent the fuzz, dust and foreign materials from getting into fuel system.

Wash your hands and do not wear working gloves.

1.

2.

3.

Follow the below procedures before starting service works for fuel system.

If the problem is from HP pump, fuel supply line or injector, prepare the clean special tools and sealing

caps to perform the diagnosis for DI engine fuel system in this manual. At this point, thoroughly clean

the related area in engine compartment.

4.

Clean the engine compartment before starting service works.

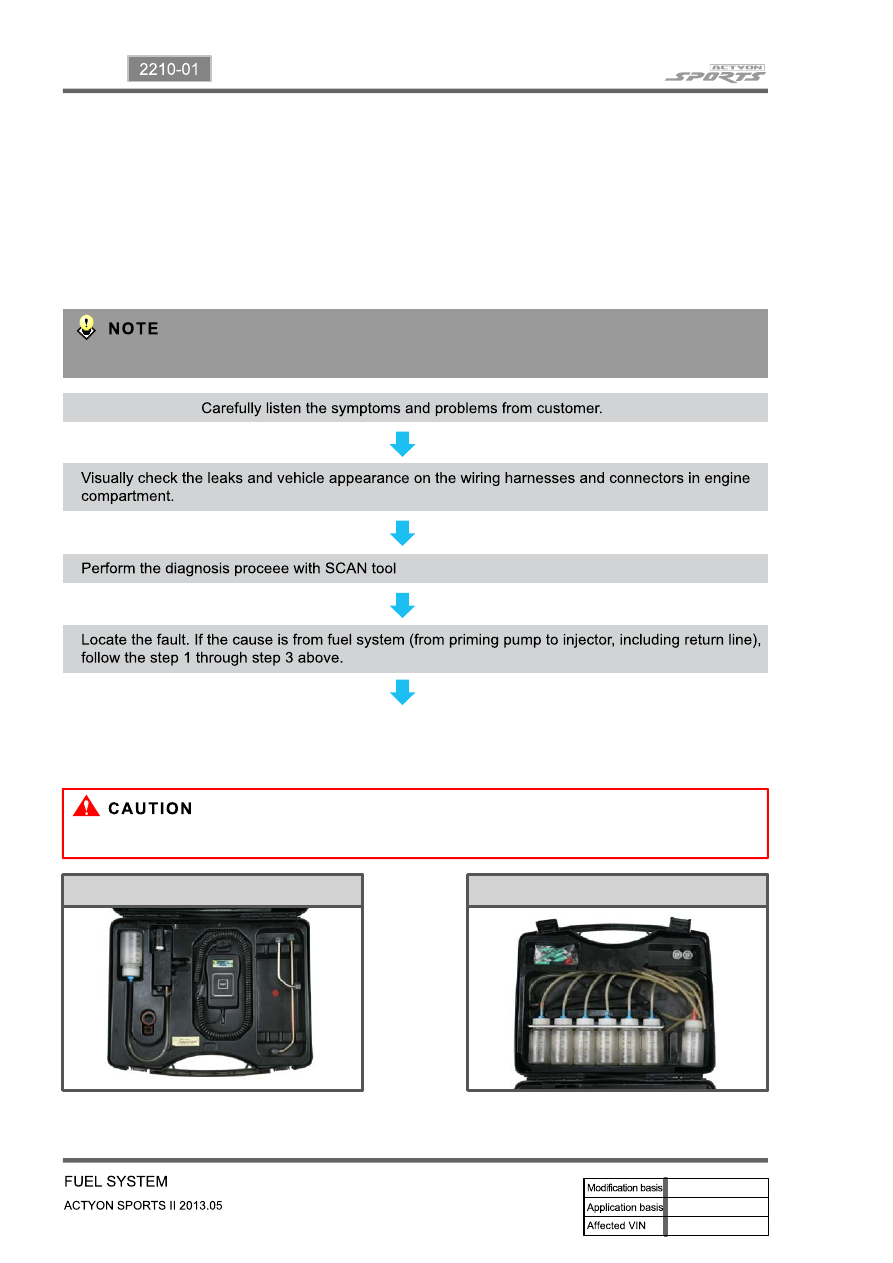

Tool kit for high pressure line

Took kit for low pressure line