SsangYong Musso. Manual - part 461

AUTOMATIC TRANSMISSION 5A-21

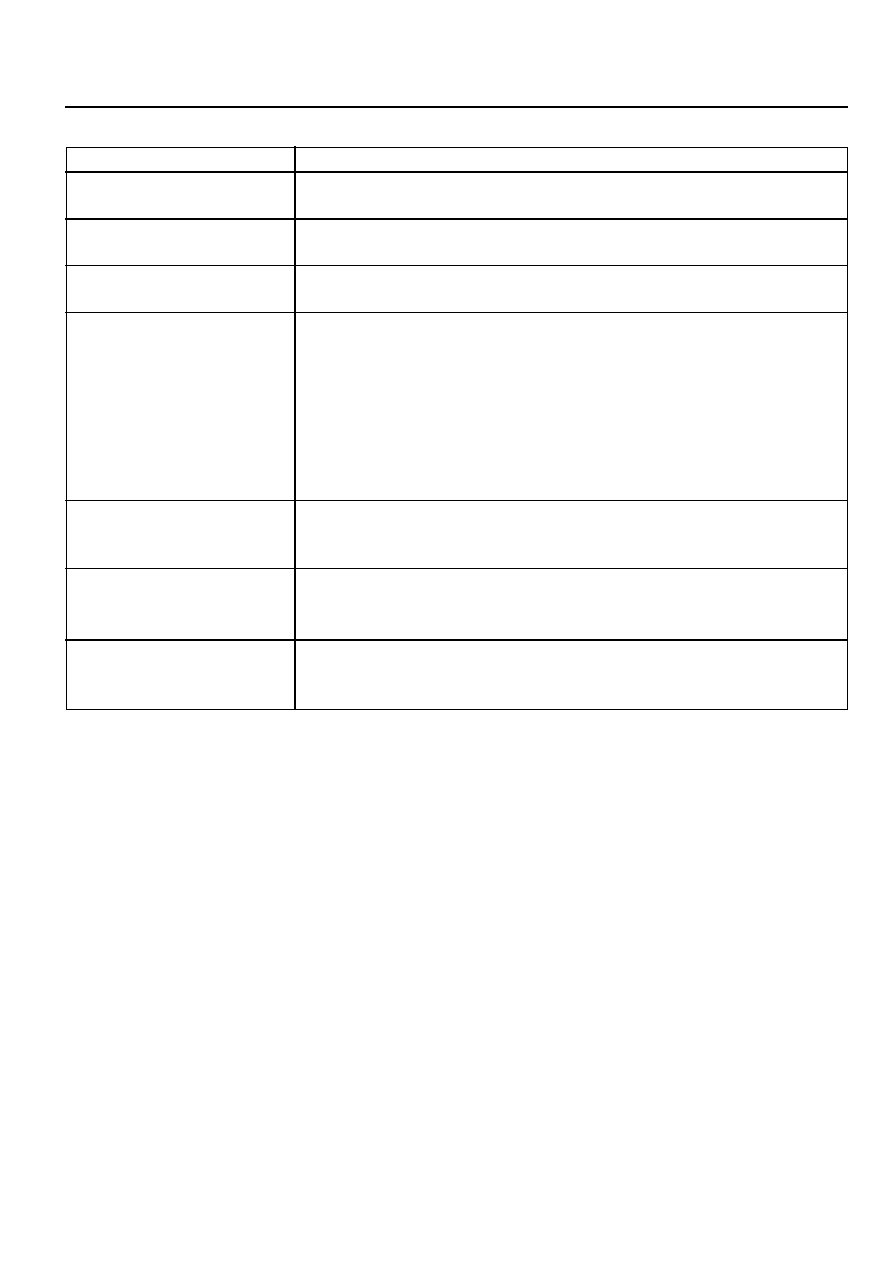

Downshift Type

RANGE ‘1’ (MANUAL ‘1’):

RANGE ‘2’ (MANUAL ‘2’):

RANGE ‘3’ (MANUAL ‘3’):

RANGE ‘D’ (DRIVE):

RANGE ‘N’ (NEUTRAL):

RANGE ‘R’ (REVERSE):

RANGE ‘P’ (PARK):

Inhibited Above

First gear operation only with inhibited engagement as a function of vehicle

speed. Engine braking is applied with reduced throttle.

First and second gear operation with inhibited engagement of second gear, as

a function of vehicle speed. Engine braking is applied with reduced throttle.

First, second and third gear operation with an inhibited third gear engagement

at high vehicle speed. Refer to the vehicle owner’s manual.

Engine braking is applied with reduced throttle.

First, second, third and fourth gear operation. First to second (1-2), first to third

(1-3), second to third (2-3), second to fourth (2-4), third to fourth (3-4), fourth

to third (4-3), fourth to second (4-2), third to second (3-2), third to first (3-1)

and second to first (2-1), shifts are all available as a function of vehicle speed,

throttle position and the time rate of change of the throttle position (forced

downshift). Lockup clutch may be enabled in 3rd and 4th gears depending on

vehicle type. Refer to the owner’s manual.

Rear band applied only, with inhibited engagement as a function of vehicle

speed, engine speed and throttle position. The inhibitor switch allows the en-

gine to start.

Reverse gear operation, with inhibitor engagement as a function of vehicle

speed, engine speed and throttle position. The inhibitor switch enables reverse

lamp operation.

Rear band applied only, with inhibited engagement as a function of vehicle

speed, engine speed and throttle position. The transmission output shaft is

locked. The inhibitor switch allows the engine to start.

Table 2.1 - Gear Selections

DRIVING MODE SELECTOR

The driving mode selector consists of a mode selection switch and indicator light. The driving mode selector is

located on the centre console. See figure 2,1.

The schedules available to be selected vary with vehicle types. Typically the driver should have the option to select

between ‘NORMAL’ , ‘POWER’ or ‘WINTER’ modes.

When ‘NORMAL’ mode is selected upshifts will occur to maximise fuel economy and the indicator lights remain

extinguished. When ‘POWER’ mode is selected upshifts will occur to give maximum performance and the ‘POWER’

mode indicator light is switched on. When ‘WINTER’ mode is selected, starting at second gear is facilitated, the

‘WINTER’ mode indicator light is switched on and the ‘POWER’ mode indicator light is switched off.

Refer to the vehicle owner’s manual for specific modes for each vehicle type.