SsangYong Musso. Manual - part 111

1F-28 ENGINE CONTROLS

SSANGYONG Y158

57

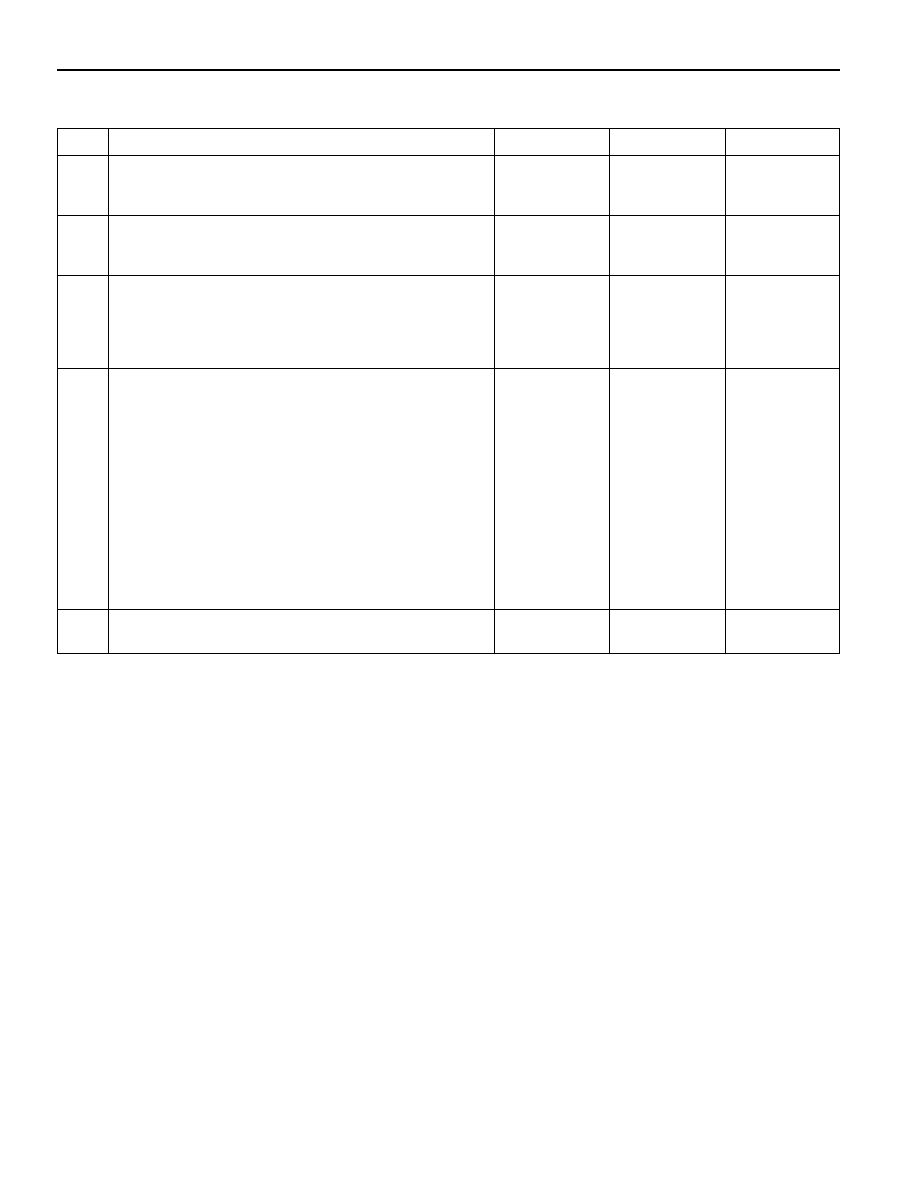

Measure the resistance of each fuel injector.

Is the resistance within the value specified (the resistance

will increase slightly at higher temperatures)?

Replace any of the fuel injectors with a resistance out of

specification.

Is the repair complete?

Check for open or short in the wire between fuel injector

harness connector terminal 1 from all of the fuel

injectors and OVPR connector terminal 6 and repair as

necessary.

Is the repair complete?

1. Check for an open between the fuel injector 1

harness connector terminal 2 and the ECM

connector terminal 63.

2. Check for an open between the fuel injector 2

harness connector terminal 2 and the ECM

connector terminal 64.

3. Check for an open between the fuel injector 3

harness connector terminal 2 and the ECM

connector terminal 65.

4. Check for an open between the fuel injector 4

harness connector terminal 2 and the ECM

connector terminal 66.

Is the problem found?

Repair the open fuel injector harness wire(s)

Is the repair complete?

Step

Action

Value(s)

Yes

No

Engine Crank But Will Not Run (2.3L DOHC) (Cont’d)

14 - 17 K

Ω

System OK

Go to Step 58

-

Go to Step 2

-

58

59

-

Go to Step 2

Go to “OVPR

Circuit Check”

-

Go to Step 61

Go to Step 31

60

-

Go to Step 2

-

61