Scania Marine engine. DI16 EMS with S6/PDE. Operator’s manual - part 4

20. Every 2,400 hours:

Checking and adjusting the valve

!

clearance

WARNING

Note: Checking and adjusting valve clearances should also be done

Block the starting device when

after the first 400 hours of operation.

working on the engine.

Valve clearances should be adjusted when the engine is cold, at least

If the engine starts

30 minutes after running.

unexpectedly, there is a

The rocker cover gaskets should be renewed as necessary. Tightening torque:

SERIOUS RISK OF INJURY.

26 Nm.

Intake valve clearance: 0.45 mm.

Exhaust valve clearance: 0.70 mm.

Tightening torque for lock nut: 35 Nm

Order of adjustment

5

1

- Turn the flywheel so that the marks on the flywheel can be seen in the

lower opening in the flywheel casing.

6

- Measure the valve clearance with a feeler gauge and adjust the valves as

2

per the order of adjustment in the table below. The correct valve

clearances are also given on the instruction plate on one of the rocker

7

3

covers:

8

4

Valve

Adjust

Adjust

Mark on

transition

intake

exhaust

flywheel

on

valves on

valves on

FLYWHEEL

cylinder

cylinder

cylinder

Cylinder numbering

TDC Down (0°)

6

7 and 8

4 and 5

TDC Up (180°)

7

1 and 5

2 and 6

TDC Down (360°)

1

2 and 4

3 and 7

TDC Up (540°)

4

3 and 6

1 and 8

21. Every 2,400 hours

Checking and adjusting the unit

injector rocker arms

Note: Checking and adjusting the unit injector rocker arms should also

be done together with the valve clearance check and adjustment

after the first 400 hours of operation.

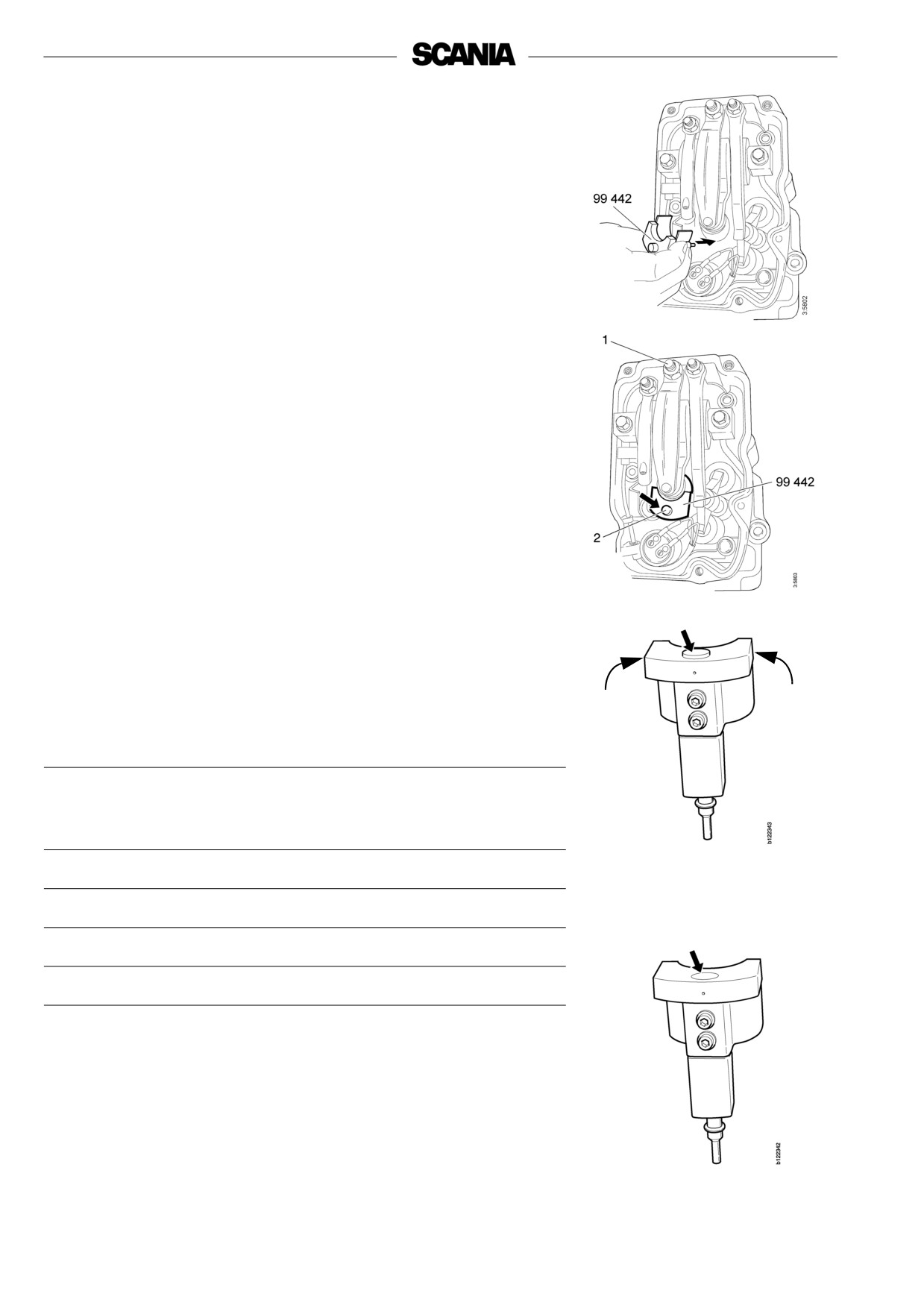

Important! The PDE31 unit injector is adjusted using setting tool 99 414

or a digital sliding caliper. The PDE32 unit injector is

adjusted using setting tool 99 442 or a digital sliding caliper.

This adjustment is essential as a fault in the position of the

unit injector can result in poor performance and possible

Dimension A=PDE31: 66.9 ± 0.1 mm

breakdown.

PDE32: 69.9 ± 0.1 mm

Dimension B=PDE31: 36.5 mm

PDE32: 38.8 mm

48

PDE31:

1. First, measure the distance (A) between plane (a) and the top edge of the

valve spring collar on the unit injector using a digital sliding calliper.

See figure.

2. Dimension (A) should be 66.9 mm for PDE31 (dimension B=36.5 mm).

3. The dimension is adjusted by undoing the lock nut and screwing the

rocker arm adjusting screw (1) to the correct measurement.

WARNING! Take care when carrying out the adjustment if the

dimension is well outside the adjustment dimension.

The spring is pre-tensioned and can cause personal

injury if it is released.

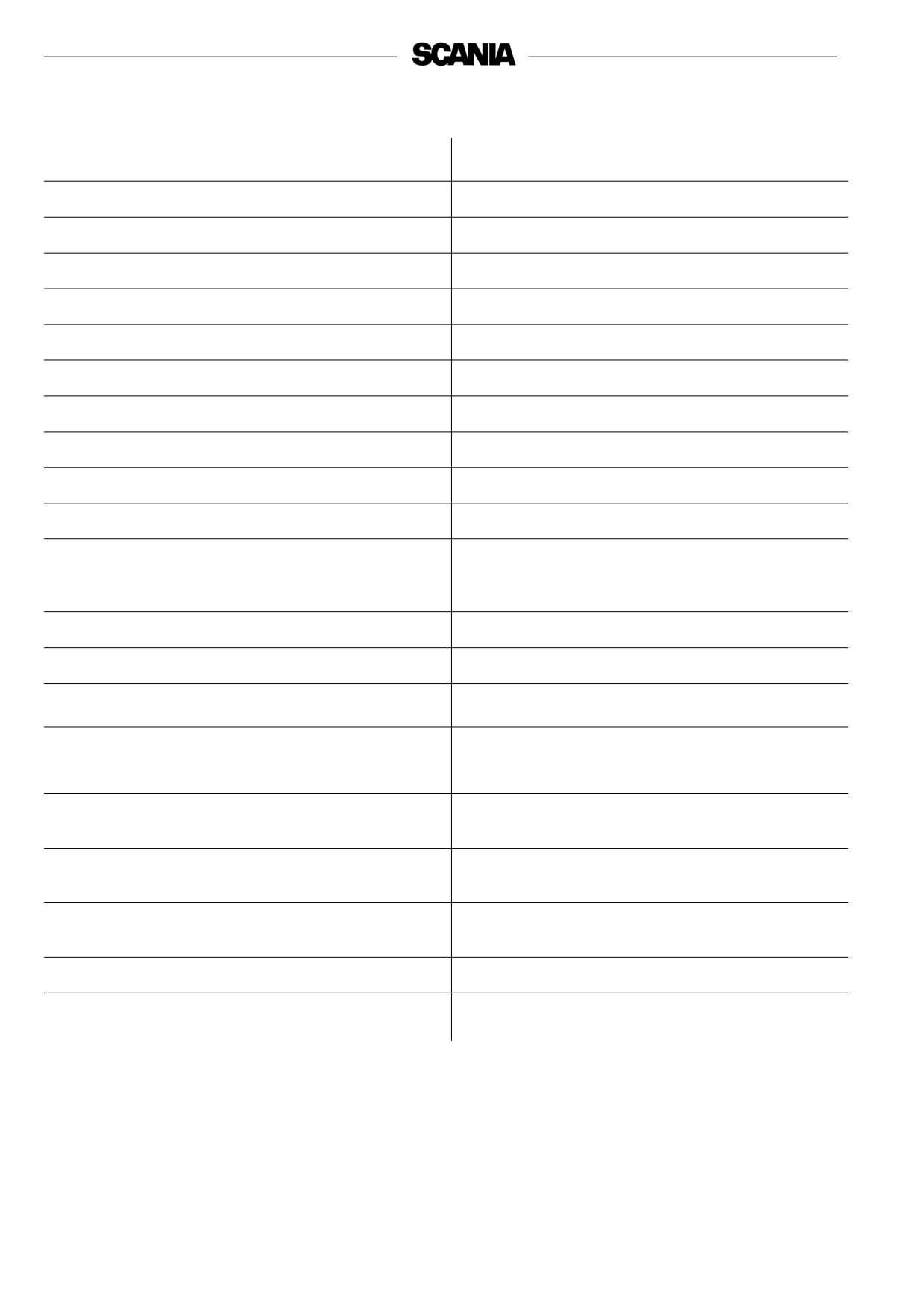

4. Position setting tool 99 414 with the metal plate around the injector

spring.

5. Finely adjust dimension (A) by simultaneously using a finger to sense

that the small piston (2) is level with the flat upper surface of the tool. It

is possible to feel differences of less than a tenth of a millimetre.

6. If the setting tool is not available, a digital sliding caliper can also be

used for fine adjustment. The rocker position is adjusted using the

adjusting screw to 66.9 ±0.1 mm as stated above.

7. Tighten the adjusting screw lock nut to 39 Nm and remove the tool.

8. The order in which the injector rocker arms are to be checked/adjusted is

shown in the table below.

Note: Additional checking and adjustment of the PDE injectors,

e.g. checking the opening pressure, must not be carried out.

Faulty injectors must always be replaced completely.

Order of adjustment:

66.9

99

414

- Turn the flywheel so that the marks on the flywheel can be seen in the

lower opening in the flywheel casing.

Valve

Adjust injector rocker

Mark on flywheel

transition on

arm on cylinder

cylinder

Piston above or below the flat

TDC Down (0°)

6

4 and 5

surface. Adjustment necessary

TDC Up (180°)

7

2 and 6

TDC Down (360°)

1

3 and 7

TDC Up (540°)

4

1 and 8

Piston level with the flat surface.

The adjustment is correct

49

PDE32:

1. First, measure the distance (A) between plane (a) and the top edge of the

valve spring collar on the unit injector using a digital sliding calliper.

See figure.

2. Dimension (A) should be 69.9 mm for PDE32 (dimension B=38.8 mm).

3. The dimension is adjusted by undoing the lock nut and screwing the

rocker arm adjusting screw (1) to the correct measurement.

WARNING! Take care when carrying out the adjustment if the

dimension is well outside the adjustment dimension.

The spring is pre-tensioned and can cause personal

injury if it is released.

4. Position setting tool 99 442 with the metal plate around the injector

spring.

5. Finely adjust dimension (A) by simultaneously using a finger to sense

that the small piston (2) is level with the flat upper surface of the tool. It

is possible to feel differences of less than a tenth of a millimetre.

6. If the setting tool is not available, a digital sliding caliper can also be

used for fine adjustment. The rocker position is adjusted using the

adjusting screw to 69.9 ±0.1 mm as stated above.

7. Tighten the adjusting screw lock nut to 39 Nm and remove the tool.

8. The order in which the injector rocker arms are to be checked/adjusted is

shown in the table below.

Note: Additional checking and adjustment of the PDE injectors,

e.g. checking the opening pressure, must not be carried out.

Faulty injectors must always be replaced completely.

Order of adjustment:

69.9

99

442

- Turn the flywheel so that the marks on the flywheel can be seen in the

lower opening in the flywheel casing

Valve

Adjust injector

Mark on flywheel

transition on

rocker arm on

cylinder

cylinder

TDC Down (0°)

6

4 and 5

Piston above or below the flat

surface. Adjustment necessary

TDC Up (180°)

7

2 and 6

TDC Down (360°)

1

3 and 7

TDC Up (540°)

4

1 and 8

Piston level with the flat surface.

The adjustment is correct

50

Preparing the engine for

storage

If the engine is not to be used for a lengthy period of time, special measures

should be taken to protect the cooling system, fuel system and combustion

chamber from corrosion and the exterior from rusting.

The engine can normally stand idle for up to 6 months. If it remains unused

for longer than this the following measures, which provide protection for

about 4 years, should be adopted. An alternative to preparing the engine for

long-term storage is to start the engine and warm it up every 6 months.

Preparing the engine for storage means:

- Thoroughly cleaning the engine.

- Running the engine for a certain time using special preservative fuel, oil

and coolant.

- Otherwise preparing the engine for storage (filter renewal, lubrication,

!

etc.).

WARNING

Ethylene glycol can

Preservative coolant

be fatal if ingested.

If the engine is to be stored with a full cooling system, use coolant containing

Avoid contact with the skin.

50 percent glycol by volume. Glycol without nitrite-based inhibitor should be

used. E.g. BASF G48 or BASF D542

Preservative fuel

- Use diesel mixed with Lubrizol 560H or the equivalent.

- Mix 1 cm³ (ml) of Lubrizol 560H in 10 dm3 (l) of fuel.

!

HANDLING LUBRIZOL 560H

Hazardous!

Contains aromatic hydrocarbons

Use spot extractors where there is a danger of vapour build-up.

Wear protective gloves and goggles when handling Lubrizol. Do not use contaminated clothing.

If it gets in your eyes: Rinse with a gentle stream of water (at least 15 minutes). Seek medical attention.

If it gets on your skin: Wash the affected area with soap and water

If you inhale it:

Fresh air, rest and warmth

Flammable:

Fire class 2A. Flashpoint +27°C.

In the event of fire: Extinguish with carbon dioxide, powder or foam

Storage:

In a well-sealed receptacle in a dry, cool place. Keep out of reach of children.

51

Preservative oil

Suitable preservative oils are available from most oil companies, e.g. Dinitrol

40 or the equivalent.

Preparations for storage

Help protect our

- Drain and flush the cooling system. Top up with preservative coolant.

environment!

- Warm up the engine on normal fuel. Stop the engine and drain the oil.

Use a container to avoid spills

- Renew the fuel filter.

when

- Fill the engine with preservative oil up to the minimum level on the

draining the oil and coolant.

dipstick.

Dispose of used oil and coolant

- Mix preservative fuel in a can. Detach the fuel pipe at the feed pump

through an authorised waste

suction line and connect a hose from the can.

disposal contractor.

- Detach the fuel pipe at the overflow valve and connect a return hose to

the can.

- Start the engine and run it at about 1,000 rpm (not single-speed engines)

for 20-25 minutes.

- Stop the engine, remove the hoses and connect the normal fuel lines.

- Remove the rocker covers and lubricate the valve mechanisms and PDE

mechanisms with preservative oil. Refit the rocker covers.

Note: The unit injectors must not be removed.

- Drain the preservative oil from the engine. Fresh engine oil can be filled

directly or when preparing the engine for use.

- Drain the coolant if the engine is not to be stored with coolant in the

system. Plug and tape over all coolant connections (if the cooling system

is not completely assembled).

- Drain the sea water system.

- Air cleaner: clean or renew the filter element.

- Cover air intakes and exhaust pipes.

- Alternator and starter motor:

- Spray with water-repellent anti-corrosive oil, CRC 226, LPS1 or the

equivalent.

- Spray the outside of bright engine parts, first with penetrating

preservative oil such as Dinitrol 25B and then with Dinitrol 112 or the

equivalent.

Winter storage

- To reduce the risk of condensation in the fuel tank during winter storage,

fill the tank with fuel.

52

- Attach a label to the engine, clearly stating the storage preparation

date and that the engine must not be started or cranked.

ENGINE PREPARED FOR

LONG-TERM STORAGE

Date

Do not start or crank!

!

Batteries

WARNING

Remove the batteries for trickle charging at the battery charging station. This

does not apply to batteries specified as maintenance-free by the manufacturer.

Wear gloves and protective

The same applies to short-term storage, even if the engine has not been

prepared for storage as above.

goggles when charging and

handling batteries.

Storage

The batteries contain a highly

After the preparations, the engine should be stored in a dry and warm place

corrosive acid.

(room temperature).

Preparation for use

(Procedure for taking the engine into operation)

- Remove plugs and tape from coolant connections, air intakes and

exhaust pipes.

- Fill the system with coolant, see page 18.

- Connect the sea water system.

- Check the oil level in the engine or top up with fresh engine oil.

- Lubricate the valve mechanisms and their pushrods and valve tappets as

well as the PDE injector mechanisms.

- Drain the preservative fuel from the fuel manifolds and fuel filter.

- Connect and bleed the fuel system, see page 43.

- Wash off any externally applied preservative oil using white spirit.

53

Technical data

General

DI16

Number of cylinders

8 (V8, 90°)

Cylinder diameter

mm

127

Piston stroke

mm

154

Displacement

dm3 (litre)

15.60

No. of main bearings

5

Firing sequence

1 - 5 - 4 - 2 - 6 - 3 - 7 - 8

Compression ratio

16:1

Engine direction of rotation viewed from rear

Anti-clockwise

Fan direction of rotation viewed from front

Clockwise

Cooling

Liquid

Valve clearances, cold engine

intake valve

mm

0.45

exhaust valve

mm

0.70

Weight with heat exchanger, without coolant or oil kg

1,550

Power

See "Engine record card"

Lubrication system

Max. oil pressure

warm engine running at a

6

speed above 1,000 rpm

bar (kp/cm2)

Normal oil pressure

warm engine at operating speed

bar (kp/cm2)

3-6

Min. oil pressure

warm engine 1,000 rpm

bar (kp/cm2)

3.0

Min. oil pressure

warm engine, idling

bar (kp/cm2)

1.4

Oil capacity, see page 27

Crankcase pressure with closed crankcase ventilationmm

-55 - +20

water column

54

Fuel system

DI16

Low idling

rpm

700 (adjustable 500-800)

Maximum full load speed

See engine card

Fuel

Diesel1

1 see page 56

Cooling system

Number of thermostats

1 (dual thermostat)

Thermostat, opening temperature

°C

79

Coolant temperature:

system at atmospheric pressure

°C

70-93

system at overpressure

°C

70 - approx. 100

Volume including heat exchanger and expansion tank

95

Electrical system

System voltage

V

24

Alternator, current

A

140

Starter motor output

kW (hp)

6.7

(9.1)

Monitors, threshold values:

oil pressure monitor

bar (kp/cm2)

1.0 ± 0.15

temperature monitor

°C

Stamped on hexagonal part of monitor

55

Fuel

Diesel

The composition of the diesel is very important for the operation and service

life of the engine and injection system. The engine output and exhaust

emissions are also dependent on the fuel quality. The requirements and

testing standards for the most important properties are described in the

Workshop Manual in sections which can be ordered from Scania dealers or

directly from Scania. Scania's address is printed on the cover.

Diesel must comply with the following standard: EN 590 (European

standard).

The table below shows the requirements for some of the most important

properties.

Property

Requirements

Viscosity at 40°C

2.0-4.5 mm2/s (cSt)

Density at 15 °C

0.82-0.86 kg/dm³

Sulphur (concentration by mass)

max 0.3%

Ignitability (CET rating)

min. 49

Flashpoint

56°C

Biofuel (low sulphur fuels)

There are 3 different classes of biofuels (SS15 54 35).

Class 1 is sulphur-free and class 2 is low in sulphur. Compared with class 3

(normal fuel), these fuels are less dense and this reduces engine power. Only

class 1 fuel should be used with a catalytic converter.

Short term use of fuel with a higher sulphur content than 0.05% by weight

will not cause permanent damage to the catalytic converter.

The catalytic converter may, however, require fuel with a low sulphur content

for some time after this to regain its normal efficiency.

56

Temperature dependence of diesel

At temperatures lower than those specified for the diesel, paraffin wax may

!

precipitate from the fuel and block filters and pipes. The engine can then lose

Important

power or stop.

The diesel is adapted for use in the specific climate of each country. If a

It is not permitted to mix

vehicle or an engine is to be operated in a temperature zone with lower

kerosene with diesel that is

temperature than normal, first identify the temperature properties of the fuel

already adapted for the climate

concerned.

concerned. The injection

The properties of the fuel when cold can be improved by adopting one of the

equipment may be damaged. All

following measures before the temperature drops:

use of paraffin other than

- If the fuel concerned cannot cope with the expected temperatures, and

kerosene is forbidden, as it

diesel is not available with the correct temperature properties, Scania

causes engine damage.

recommends that an electric fuel heater is installed as a preventive

measure.

- The low temperature properties of diesel may be improved by adding

kerosene as a preventive measure. A maximum of 20% may be added.

When refuelling, the kerosene should be added first, so that it mixes

thoroughly with the diesel.

!

Note: It is prohibited to use kerosene in engine fuel in some countries.

Important

- To prevent water in the fuel from freezing and forming ice, a maximum

of 0.5-2% alcohol (isopropanol) may be added.

It is not permissible to mix

petrol with diesel. Petrol may

Drain fuel tanks and drain or renew fuel filters regularly.

cause wear to the unit injectors

and it may also cause damage to

the engine.

57

EC declaration of conformity

The following declaration of conformity applies to the DI16 45M with an

engine output of 662 kW. The declaration guarantees that the engine is

classified as suitable for recreational craft according to directive 94/25/EC.

58

Alphabetical index

Air cleaner

40

Oil level

27

Air cleaner, vacuum indicator

40

Oil pressure

22

Air filter, element

40

Preface

2

Batteries

44

Preparation for use

53

Battery, renewing

45

Preparations for storage

51

Bleeding, fuel system

43

Running

20

Certified engines

5

Checks after running

23

Safety information

6

Checks before running

19

Safety precautions for care and maintenance ..8

Coolant

33

Safety precautions for handling materials

8

Coolant level

31

Safety precautions for running the engine

7

Coolant level monitor

45

Starting the engine

19

Coolant temperature

21

Stopping the engine

23

Coolant, changing

35

Storage

53

Cooling system

31

Cooling system, cleaning

36

Technical data

54

Corrosion inhibitor

35

Troubleshooting, control unit

14

Troubleshooting, coordinator

16

Drive belt

46

Type designations

10

Electrical system

44

Unit injector

48

EMS sensors

13

Engine speed

20

Vacuum indicator

40

Environmental responsibility

4

Valve clearance

48

Filter, air cleaner

40

Warranty

1

Filter, fuel

42

First start

18

Flash codes, control unit

15

Flash codes, coordinator

17

Fuel filter, renewing

42

Fuel level

42

Fuel specifications

56

Fuel system

42

Fuel system, bleeding

43

Glycol

33

Inspection schedule

25

Leakage

47

Lubricating oil pressure

22

Lubrication system

26

Maintenance

24

Oil analysis

26

Oil capacity

27

Oil change

27

Oil filter

28

Oil filter

30

Oil grade

26

59

Scania Assistance

Wherever you are, you can always get assistance from the Scania service organisation, Scania Assistance, all day,

every day of the year. Using Scania Assistance is free, but the cost of repairs, spare parts and help from mechanics

will be debited.

Always call the contact for your country.

AR

0800 999 722 642

IE

+353 71 9634000

AT

+43 1 256 44 11

IT

+39 0461 996 222

AU

1300 SCANIA

KR

+82 1588 6575

1300 722642

LU

+32 226 400 000

BE

+32 2 264 00 00

MA

+34 91 678 92 13

BG

+359 886 660001

MX

01 800 4SCANIA

BR

0800 019 42 24

NL

+31 70 4182666

CH

+41 800 55 24 00

NO

+47 223 217 00

CL

188 800 722 642

PL

+48 602 622 465

CZ

+420 225 020 225

PT

+48 91 678 9247

DE

+49 261 887 8888

RO

+40 723 27 27 26

DK

+45 333 270 44

SE

+46 42 100 100

ES

+34 91 678 80 58

SK

+421 903 722 048

FI

+358 10 555 24

TR

+90 212 335 04 40

FR

+33 2 414 132 32

TZ

+255 78 472 2642

GB

0 800 800 660

UY

0800 8351

+44 1274 301260

ZA

0800 005 798

GR

+30 6944 420 410

+27 11 661 9823

HU

+36 209 727 197

Other countries: +46 8 52 24 24

24

Note: Calls will be recorded for training purposes.

60