Scania OC16 Gas. Industrial engine en-GB 2 831 273. Operator’s manual - part 4

Fuel system

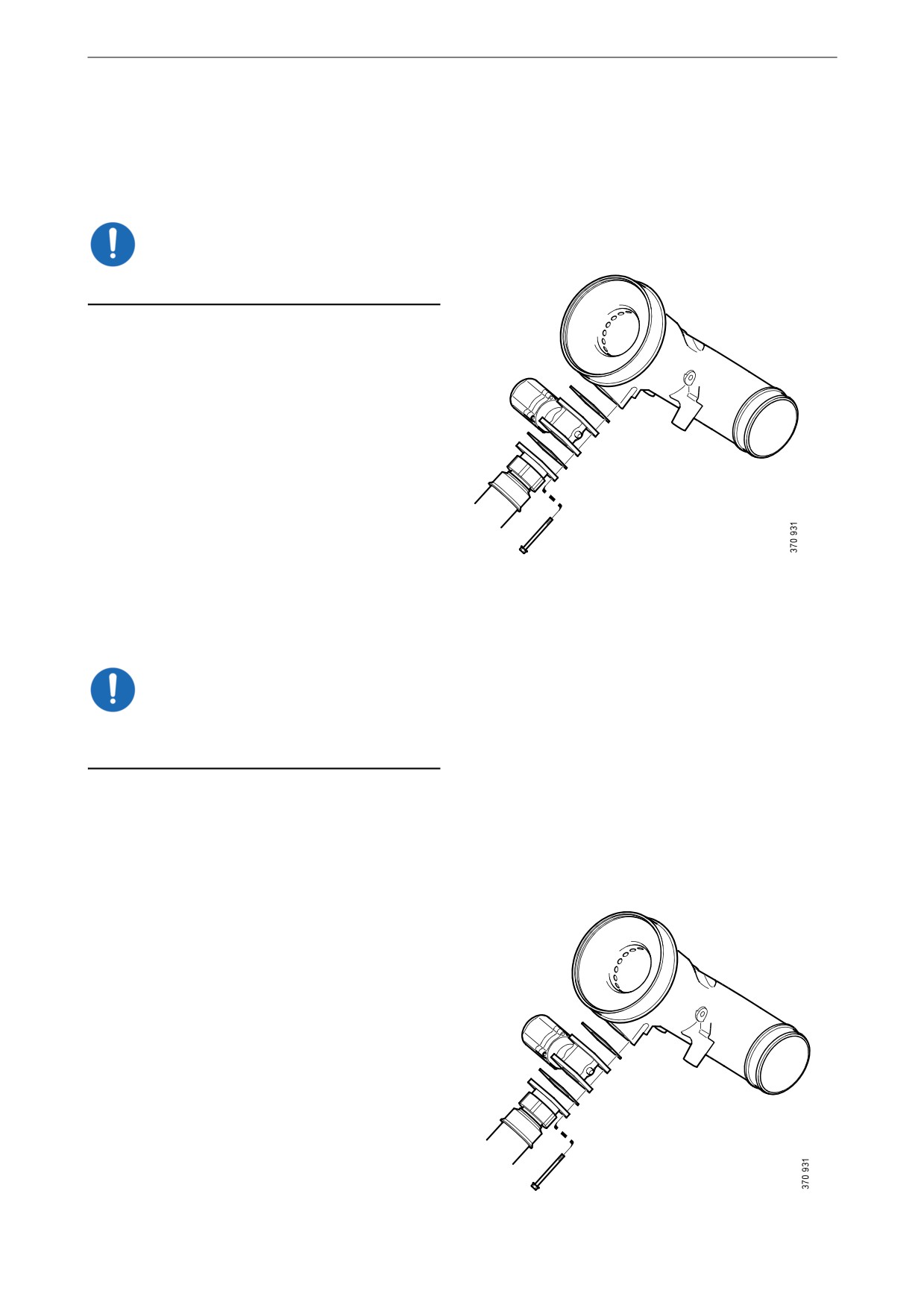

Cleaning the throttle at the

gas mixer

This procedure applies only if pure biogas is

used as fuel.

IMPORTANT!

Read the safety precautions before starting work.

1. Detach the harness-to-component connector

from the throttle.

2. Remove the screws and detach the fuel hose

and the throttle.

3. Protect the throttle electrical connection

from moisture.

4. Clean the throttle with soap and water. Use a

soft brush to remove stubborn dirt.

IMPORTANT!

Only use soap and water. Solvents and degreas-

ing agents can damage the throttle.

5. Rinse the throttle with hot water.

6. Dry off the water.

7. Spray the outside of the throttle with water-

repellent anti-corrosive oil, for example

LPS1 or equivalent. Make sure that the oil

reaches the holes for the throttle shaft in the

throttle housing.

8. Fit the gas mixer housing.

9. Renew the gaskets.

10. Fit the throttle and gas connection.

11. Check the fuel system is not leaking. See the

following section.

48

Fuel system

Leak testing after mainte-

nance of the fuel circuit

This procedure applies only if pure biogas is

used as fuel.

Special tool

Number

Designation

2 541 520

Pressure testing kit

Calibration of the pressure testing

equipment

1. Connect pressure regulator 2 301 551 to the

compressed air.

2. Block the connection nipple and open the

pressure regulator valve.

49

Fuel system

3. Adjust the pressure regulator so that the ma-

nometer shows 7 psi.

50

40

60

30

70

20

80

10

90

0

100

4. Lock the pressure regulator adjustment rota-

ry control and close the valve.

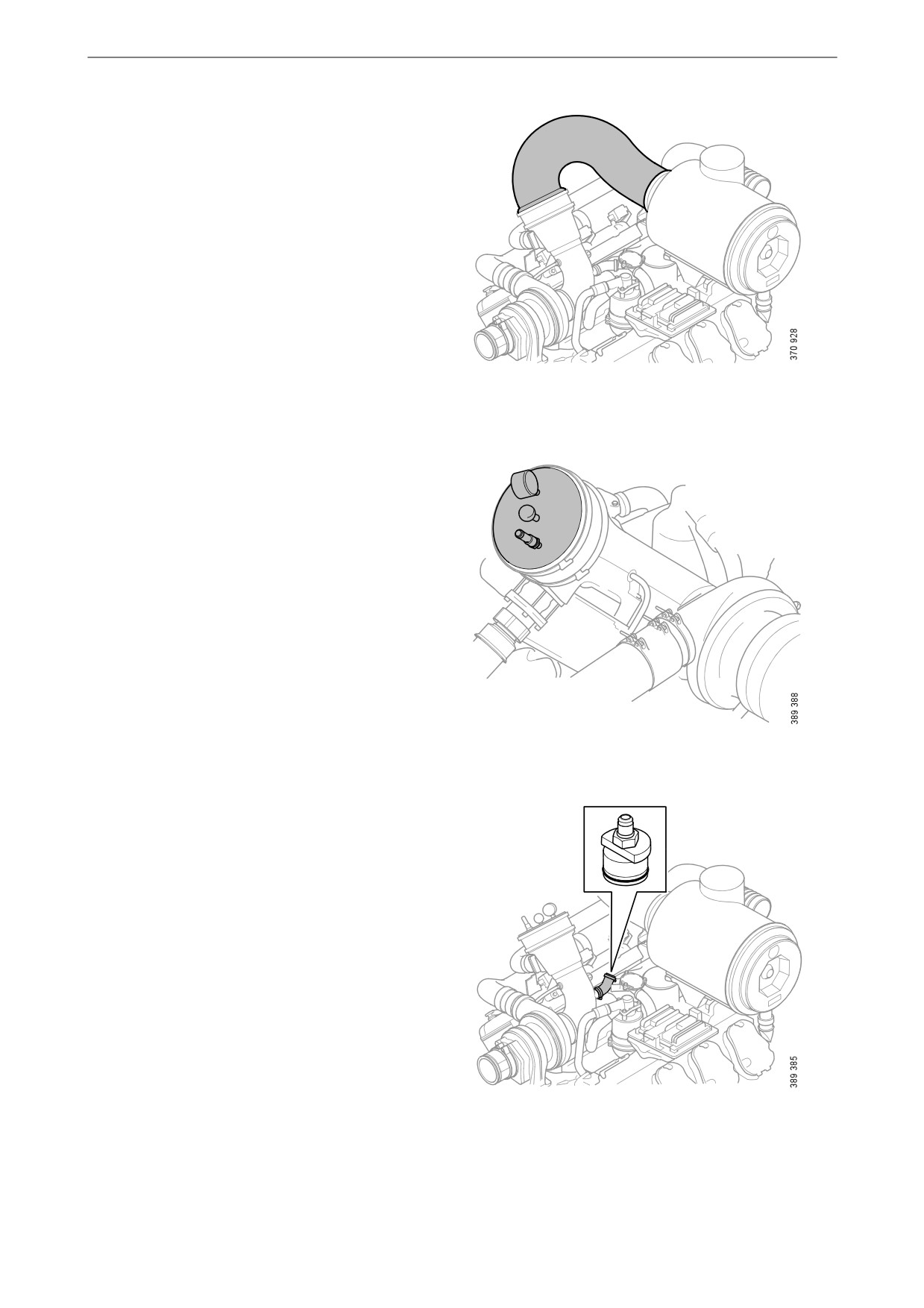

Leak testing the intake system up-

stream of the throttle

1. Undo the hose clamps.

2. Turn the charge air pipe downwards.

3. Close the nipple on pressure cap 2 655 714

and fit the cover to the hose spigot.

4. Tighten the hose clamps.

50

Fuel system

5. Remove the air pipe between the air cleaner

and the gas mixer.

6. Fit pressure cap 2 541 521 in the hose spigot

on the gas mixer.

7. Detach the crankcase ventilation connection.

8. Fit cover 2 655 695.

9. Connect pressure regulator 2 301 851 to cov-

er 2 655 695.

51

Fuel system

10. Open the valve on pressure regulator

2 301 851.

11. Monitor the pressure on pressure cap

2 541 521. The manometer should indicate a

pressure below 0.3 bar. Greater pressure may

damage the engine.

52

Fuel system

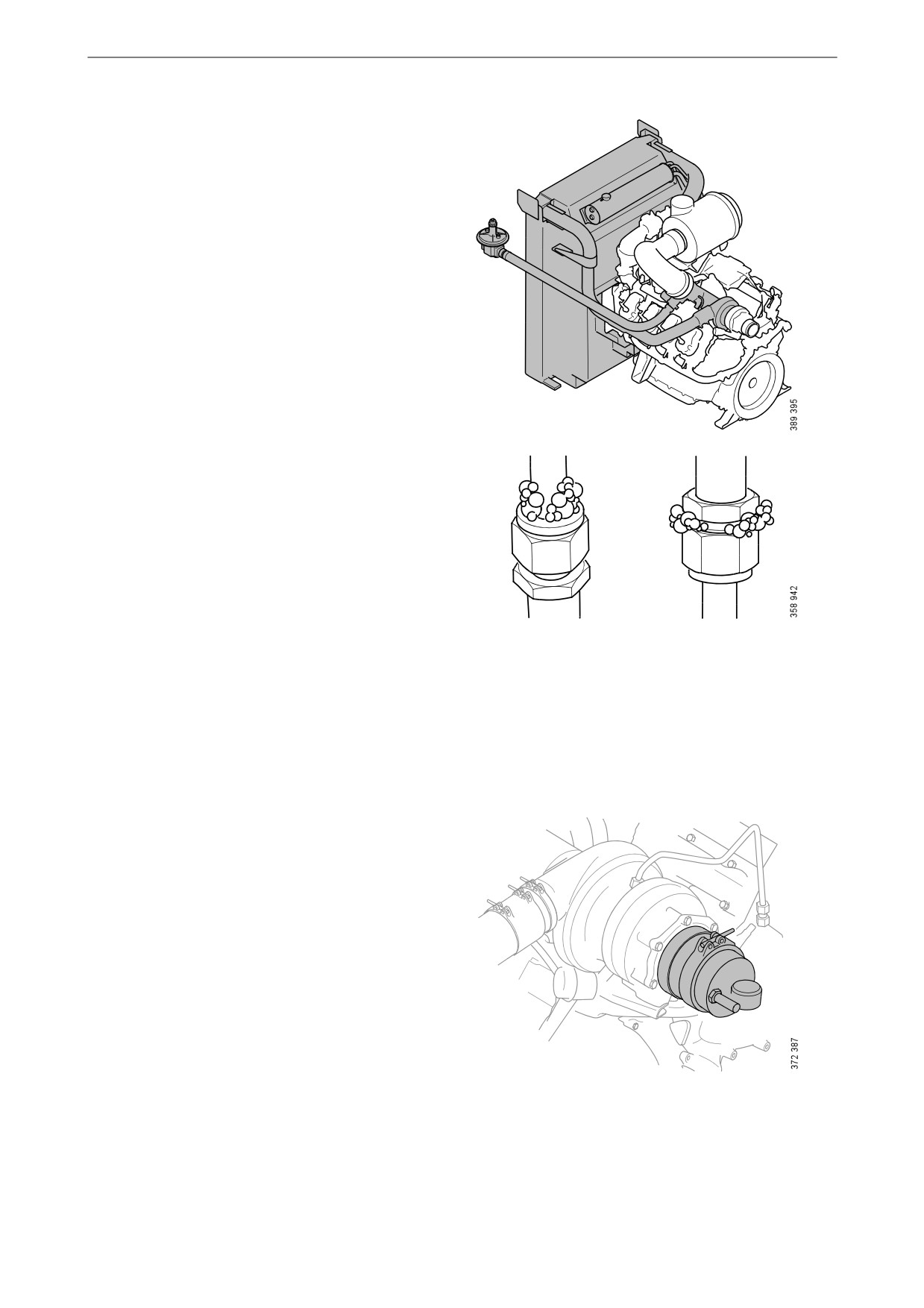

12. Use leak detection spray to locate any gas

leakage. If there is a gas leak, bubbles form

upon application of leak detection spray.

Be careful in areas where work has been car-

ried out or where a joint has been cut.

13. If you discover a leak, rectify the leakage and

repeat the leak tracing.

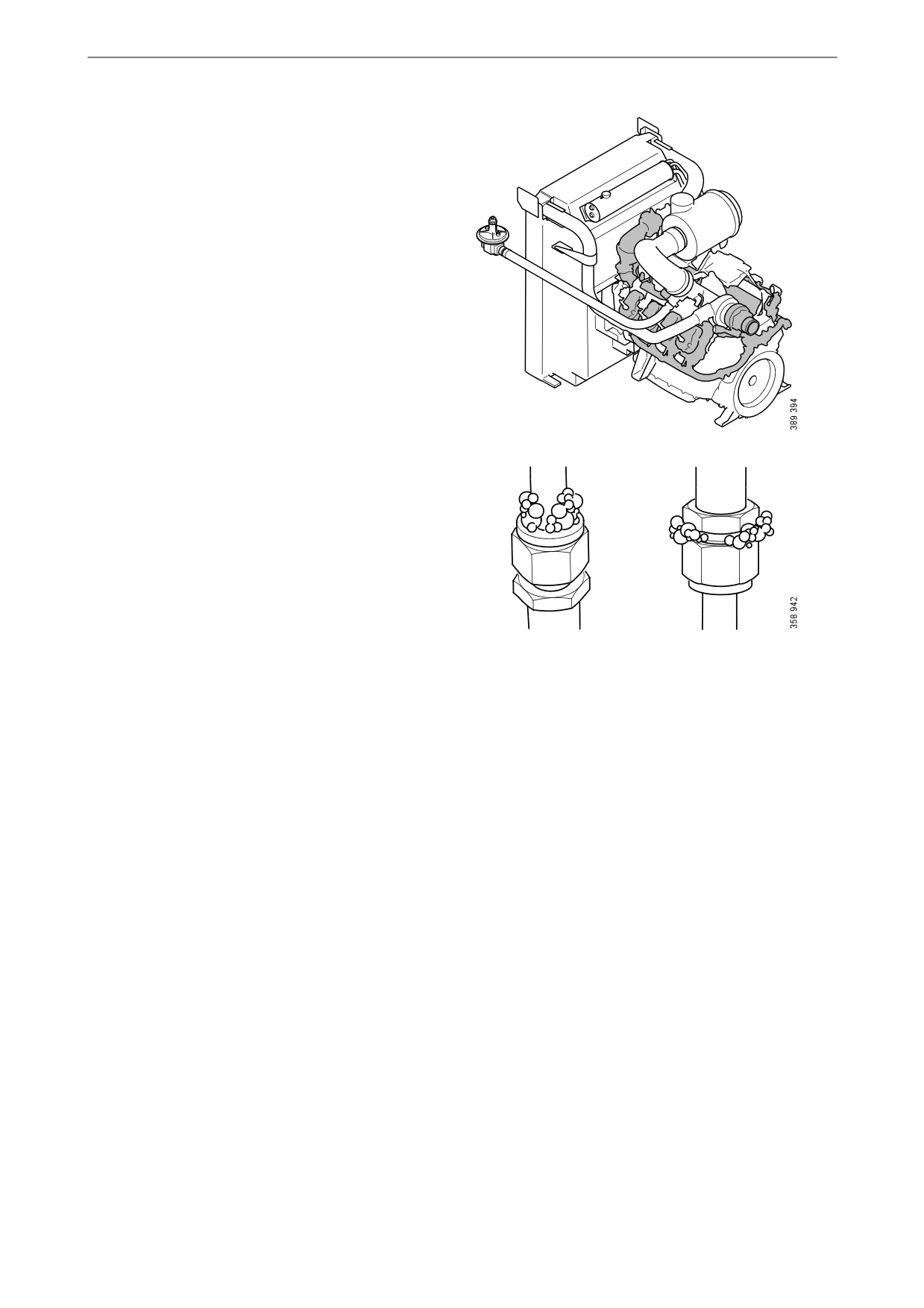

Leak testing the intake system down-

stream of the throttle

1. Remove the V-clamp and move the exhaust

pipe to one side.

2. Remove the O-ring from the pressure testing

equipment 2 284 630. Fit adapter 2 541 522

and the pressure testing equipment and plug

the pneumatic connection with cover

2 655 696.

Fit the pressure testing equipment with

adapter.

53

Fuel system

3. Remove the hose spigot and pressure cap

2 655 714 from the charge air pipe.

4. Open the nipple on pressure cap 2 655 714.

5. Fit adapter connection 2 655 697 to the pres-

sure regulator and connect it to pressure cap

2 655 714.

6. Fit the hose spigot and pressure cap

2 655 714 at the throttle housing.

7. Open the valve on pressure regulator

2 301 851.

8. Monitor the pressure on pressure testing

equipment 2 284 630. The manometer

should indicate a pressure below 0.3 bar.

Greater pressure may damage the engine.

IMPORTANT!

The pressure must not exceed 0.3 bar. A higher

pressure may damage the turbocharger.

54

Fuel system

9. Use leak detection spray to locate any gas

leakage. If there is a gas leak, bubbles form

upon application of leak detection spray.

Be careful with areas where work has been

carried out or where a joint has been cut.

The exhaust system up to the turbocharger

outlet is pressurised, but does not need to be

checked.

10. If you discover a leak, rectify the leakage and

repeat the leak tracing.

55

Fuel system

Checking deposits in the

combustion chamber

The procedure only applies if pure biogas is used

as fuel, and after cleaning the flame arrestor and

throttles in accordance with the previous two

sections.

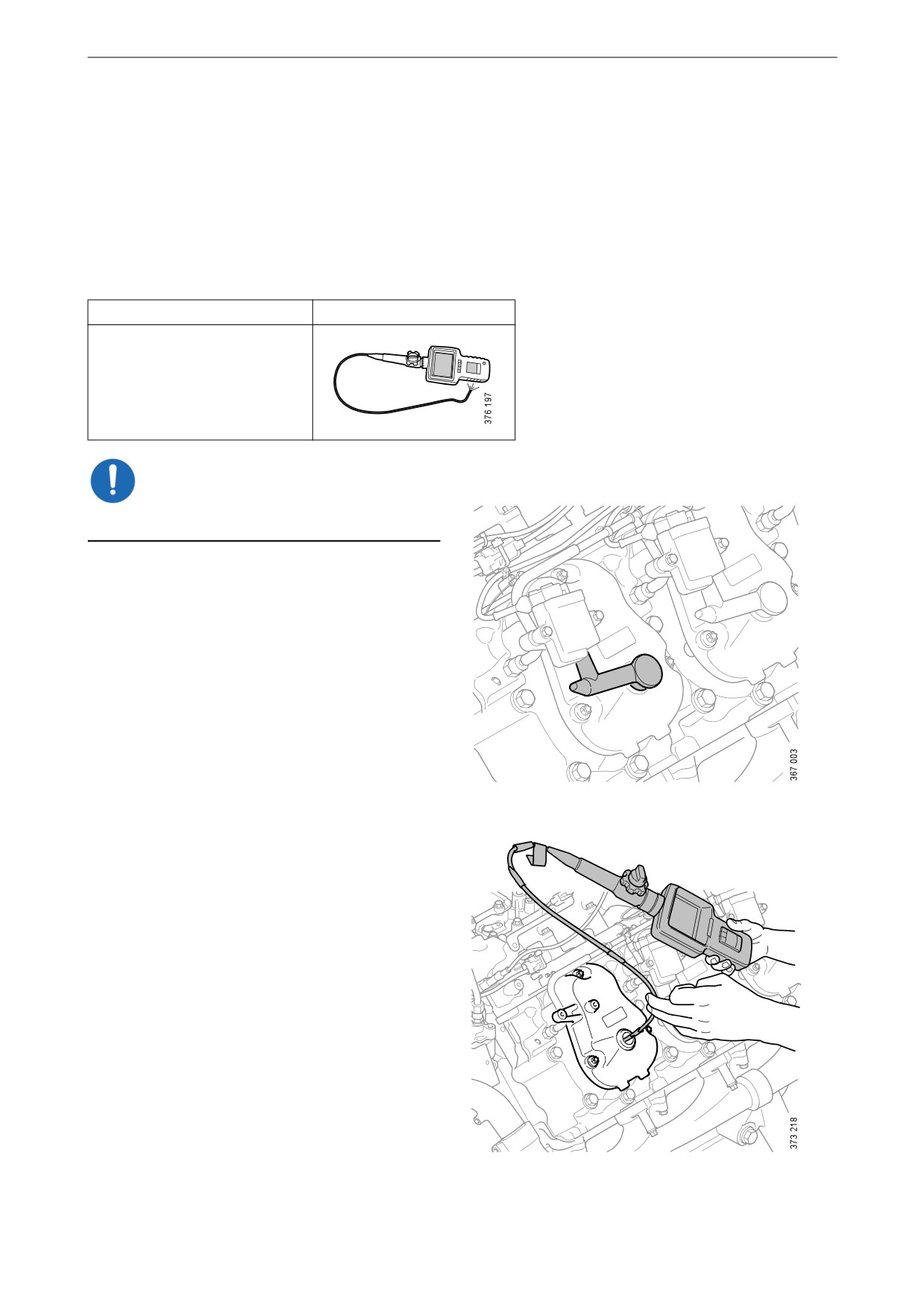

Tools

Designation

Illustration

Endoscope

IMPORTANT!

Read the safety precautions before starting work.

1. Remove the spark plug connection and the

spark plug. See the section Renewing the

spark plugs.

2. Check if there are any deposits in the com-

bustion chamber using an endoscope.

3. Check the amount of deposits on the top of

the piston.

The cylinder, piston and the valve head must

be cleaned if

- deposits on the top of the piston are flak-

ing,

or if

- the deposit protrudes at least 5 mm from

the valves.

The cleaning procedure is described in the

Workshop Manual, which can be ordered

from a Scania dealer or directly from Scania.

4. Repeat steps 1-3 on the other cylinders.

56

Electrical system

Electrical system

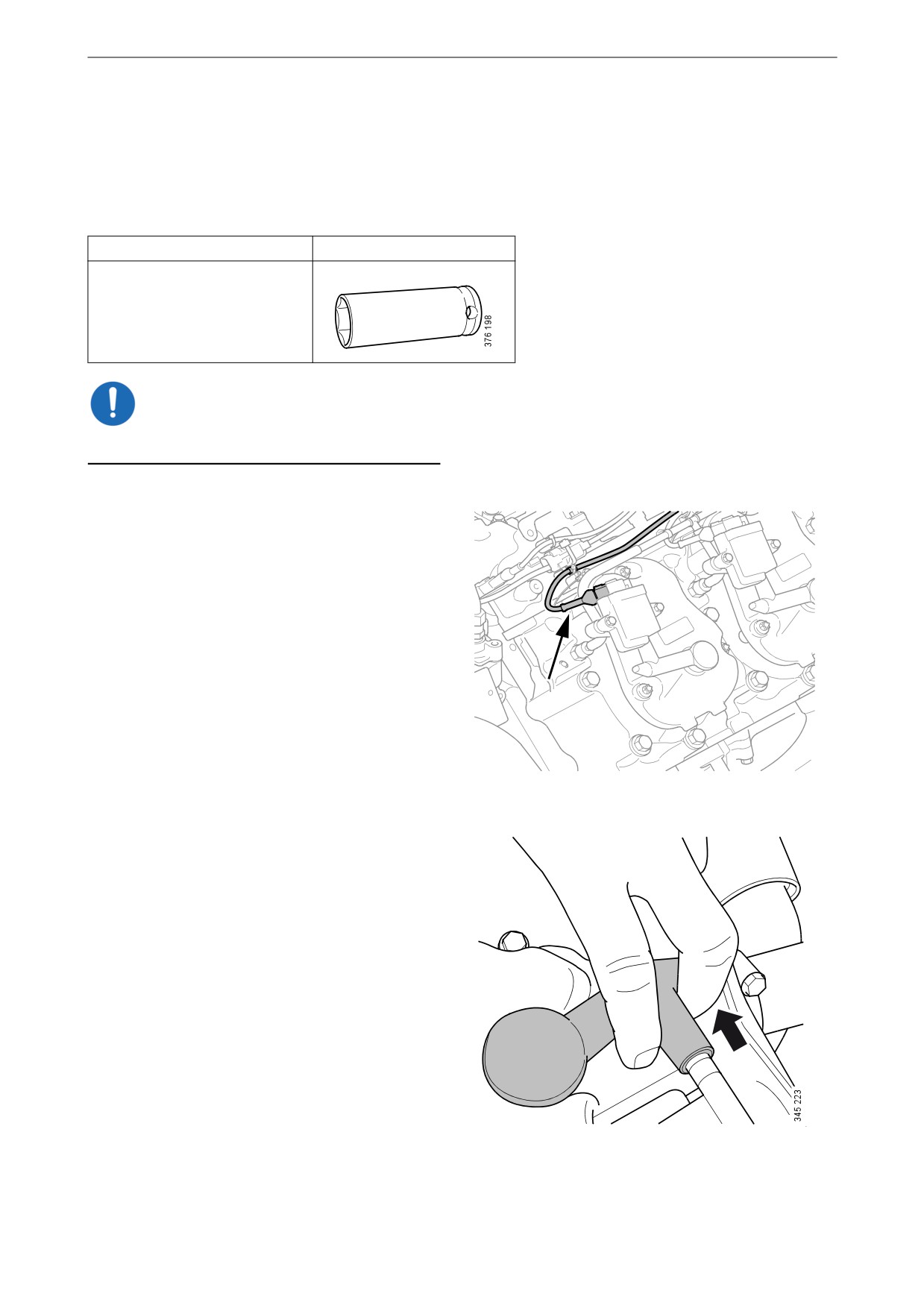

Renewing the spark plugs

Tools

Designation

Illustration

Spark plug socket

IMPORTANT!

Read the safety precautions before starting work.

1. Disconnect the ignition coil harness-to-com-

ponent connector.

2. Twist off the spark plug connector arm later-

ally.

57

Electrical system

3. Remove the spark plug connector by pulling

it straight upwards.

IMPORTANT!

Do not pull on the arm as this could damage the

spark plug connector.

4. Check that the spark plug connector does not

have any visible damage.

5. Unscrew the spark plug using the spark plug

socket.

IMPORTANT!

Do not touch the spark plug insulator with your

fingers. If this occurs, clean the insulator with al-

cohol.

6. Place the new spark plug in the spark plug

socket and tighten the spark plug. Tightening

torque 30 Nm (22 lb-ft).

IMPORTANT!

Do not lower the spark plug through the rocker

cover since this could cause the gap between the

spark plug electrodes to be incorrect. Always

place the spark plug in the spark plug socket be-

fore fitting. The correct gap between the spark

plug electrodes is 0.25 mm.

7. Fit the spark plug connector.

58

Other

Other

3

2

Checking the drive belt

5

IMPORTANT!

2

Before starting, make a note of how the drive belt

is fitted. Refit the drive belt with the same direc-

tion of rotation as it had before removal.

4

1. Check the drive belt thoroughly, particularly

at the idler rollers.

2. Check the drive belt for cracks. Renew the

1

drive belt if deep cracks have formed.

Example of a drive belt.

Note:

1. Crankshaft

Small and shallow cracks are normal and form

2. Idler roller

after only a few hours of operation. They do not

3. Alternator

mean that the drive belt needs to be renewed. If

4. Belt tensioner

there are many deep cracks, or if parts of the

5. Coolant pump

drive belt have started to come off, the drive belt

must then be renewed.

Example of a minor crack in the drive belt. The drive

The drive belt has deep cracks and must be renewed.

belt can be refitted.

59

Other

3. Check drive belt wear. Renew the drive belt

if it is too worn.

The drive belt is starting to become worn, but can be

The belt is worn down to the cord. The drive belt

refitted.

must be renewed.

Checking for leaks

WARNING!

If there is leakage in the fuel system, contact

your nearest Scania workshop immediately.

IMPORTANT!

If there is a major oil or coolant leak, contact

your nearest Scania workshop.

1. Start the engine.

2. Check for oil, coolant, fuel, air or exhaust

leaks.

3. Tighten or renew leaking connections.

Check the overflow holes which show

whether the O-rings between the cylinder

liners and crankcase are leaking.

4. Check whether the drain hole on the coolant

pump is blocked. If there is a leak, renew the

seal in the pump or the complete coolant

pump.

60

Other

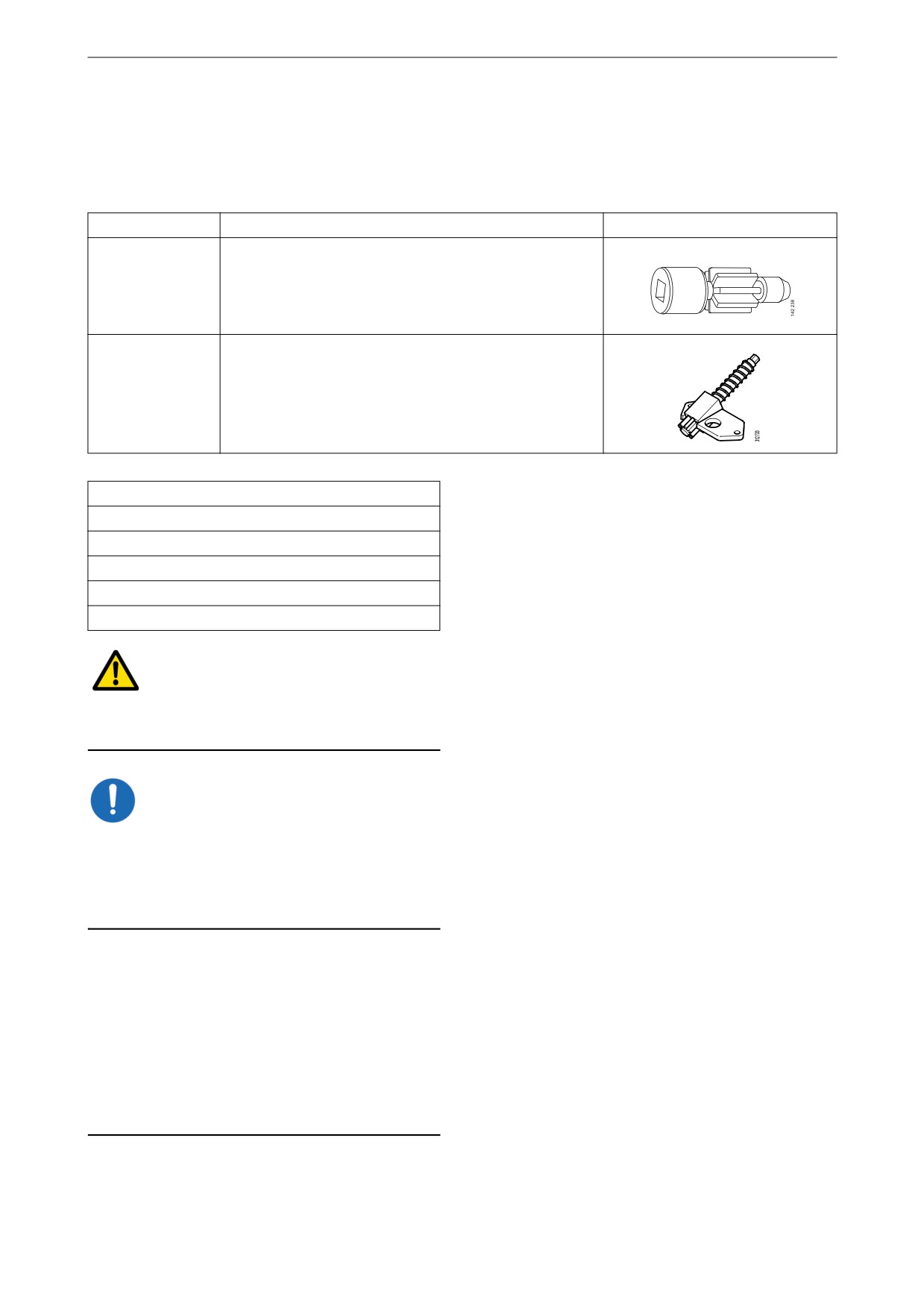

Checking and adjusting the

valve clearance

Special tool

Number

Designation

Illustration

99 309

Turning tool for rotating the flywheel from below.

2 402 509

Turning tool for rotating the flywheel from above

Other tools

Torque wrench, 0-50 Nm

Waterproof felt-tip pen

0.45 and 0.80 mm feeler gauges

Flash light

Mirror

WARNING!

Block the starting device. If the engine starts un-

expectedly, there is a serious risk of injury.

IMPORTANT!

The engine must be cold when the work is car-

ried out.

Remember to remove the turning tool from the

flywheel after adjustment.

Note:

Carry out the working without pausing, so that

no step is overlooked.

Carry out a check and adjustment of the valve

clearances one more time after the first 500 hours

of operation. After this, adjustment according to

the regular interval takes place, which is every

2,000 operational hours.

61

Other

The reference information UP TDC, DOWN

TDC and the angle indications listed in the table

below are engraved on the flywheel. Depending

on the engine installation, this information is vis-

ible in one of the windows, either furthest up or

furthest down on the flywheel. See illustration.

Valve clearance, specifications

Intake valve

0.45 mm (0.018 in)

Exhaust valve

0.80 mm (0.032 in)

Upper and lower window to read the engraving on

Tightening torque

the flywheel.

Lock nut for valves

35 Nm (26 lb/ft)

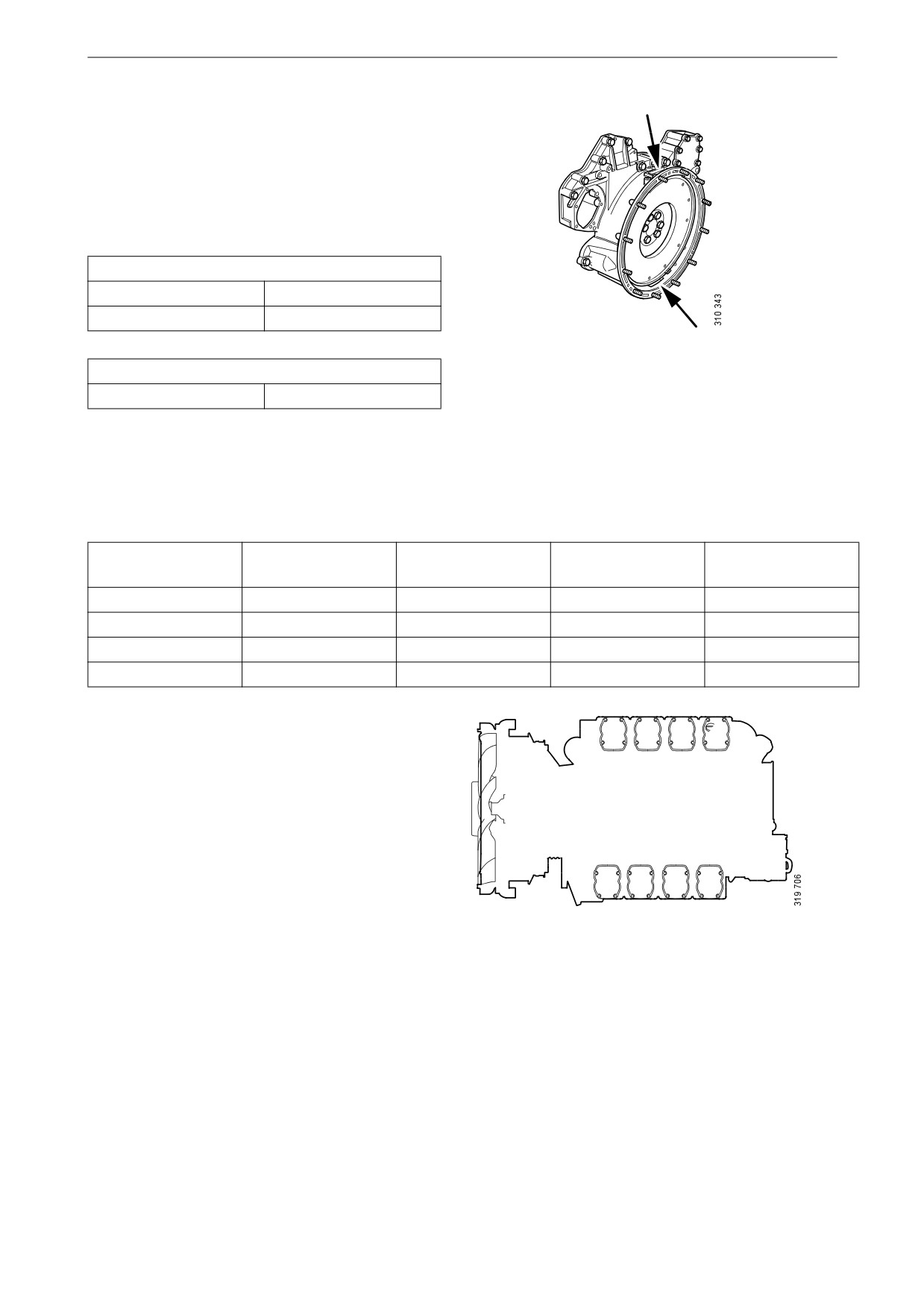

Adjust valves according to the table below. Fol-

low the respective column depending on whether

you are reading the engraving on the flywheel in

the lower or the upper window. Start adjustment

at the top of the table.

Reading in the low-

Valve transition on

Adjust intake valve

Adjust exhaust

Reading in the up-

er window

cylinder

on cylinder

valve on cylinder

per window

DOWN TDC (0°)

6

7 and 8

4 and 5

UP TDC (180°)

UP TDC (180°)

7

1 and 5

2 and 6

DOWN TDC (0°)

DOWN TDC (360°)

1

2 and 4

3 and 7

UP TDC (540°)

UP TDC (540°)

4

3 and 6

1 and 8

DOWN TDC (360°)

1

2

3

4

5

6

7

8

Order of cylinders.

62

Other

1. Clean the rocker covers and the area around

them.

2. Remove the rocker covers.

3. Use the turning tool appropriate to the instal-

lation of the engine. Tool 99 309 is used to

rotate the flywheel from the underside of the

engine and tool 2 402 509 is used from the

top side.

4. Start adjusting one cylinder according to the

table. Rotate the flywheel until the correct

engraving can be read on the flywheel. It

may be necessary to rotate it more than 1 rev-

olution.

Rotate the flywheel in the rotational direc-

tion of the engine, which is clockwise

viewed from the front of the engine and anti-

3

clockwise viewed from the back of the en-

gine.

During a valve transition, the exhaust valve

(the long arm) is closing at the same time as

4

the intake valve is opening.

The UP TDC engraving on the flywheel is

now visible in the window furthest up on the

flywheel. The DOWN TDC engraving is vis-

5

ible in the lower window.

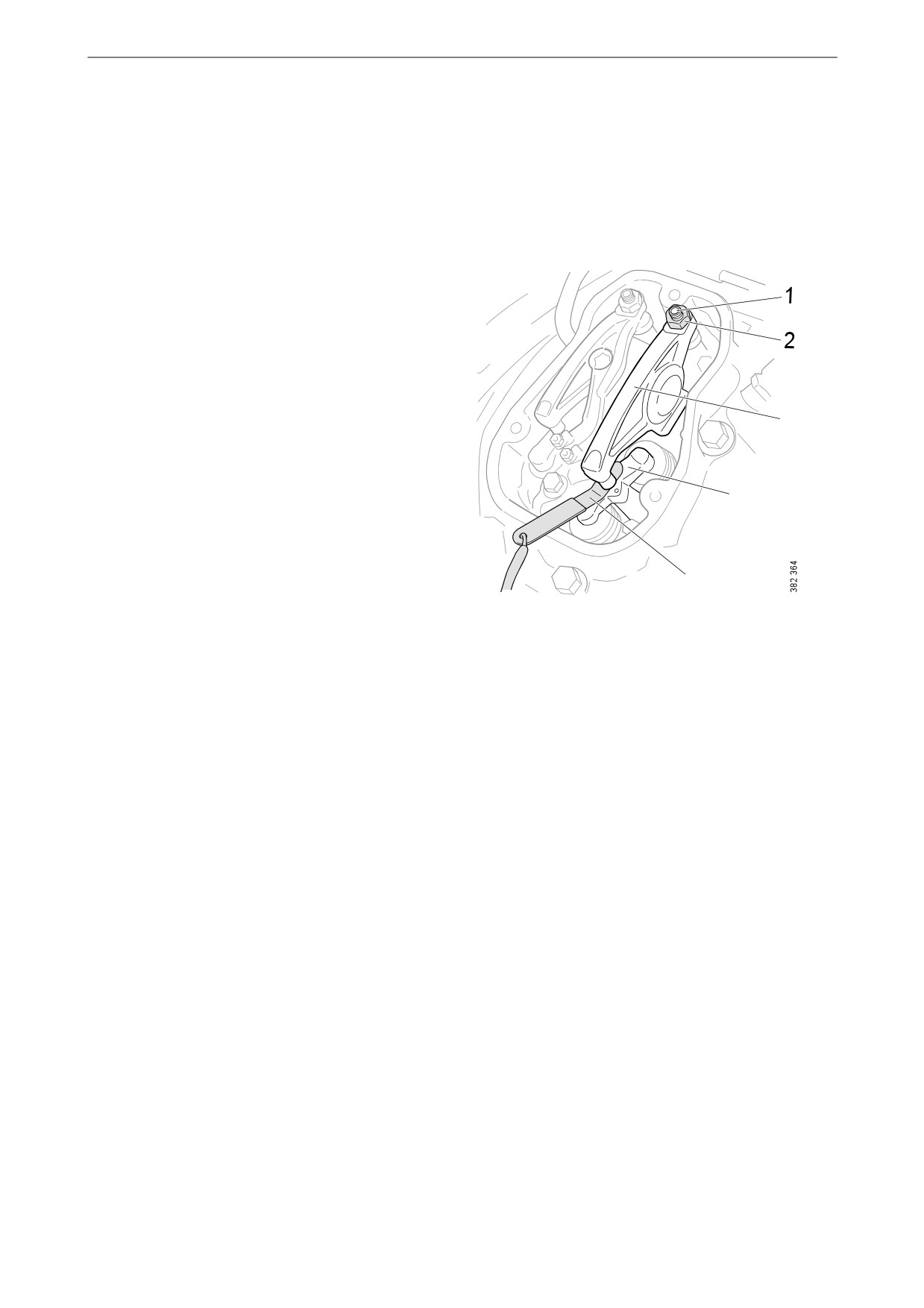

1.

Adjusting screw

5. Read the table on the previous page to see

2.

Lock nut

which valve to adjust.

3.

Rocker arm

6. Stick the feeler gauge under the pressure pad

4.

Valve bridge

of the rocker arm and check the valve clear-

5.

Feeler gauge

ance.

7. If necessary, adjust the valve clearance by

a) loosening the lock nut on the end of the

rocker arm

b) adjusting the valve clearance with the ad-

justing screw

c) tightening the lock nut.

8. Mark the rocker arm with the felt-tip pen and

then continue with the next cylinder accord-

ing to the table.

63