Scania DC16 PDE. Industrial engine en-GB 2 823 990. Operator’s manual - part 3

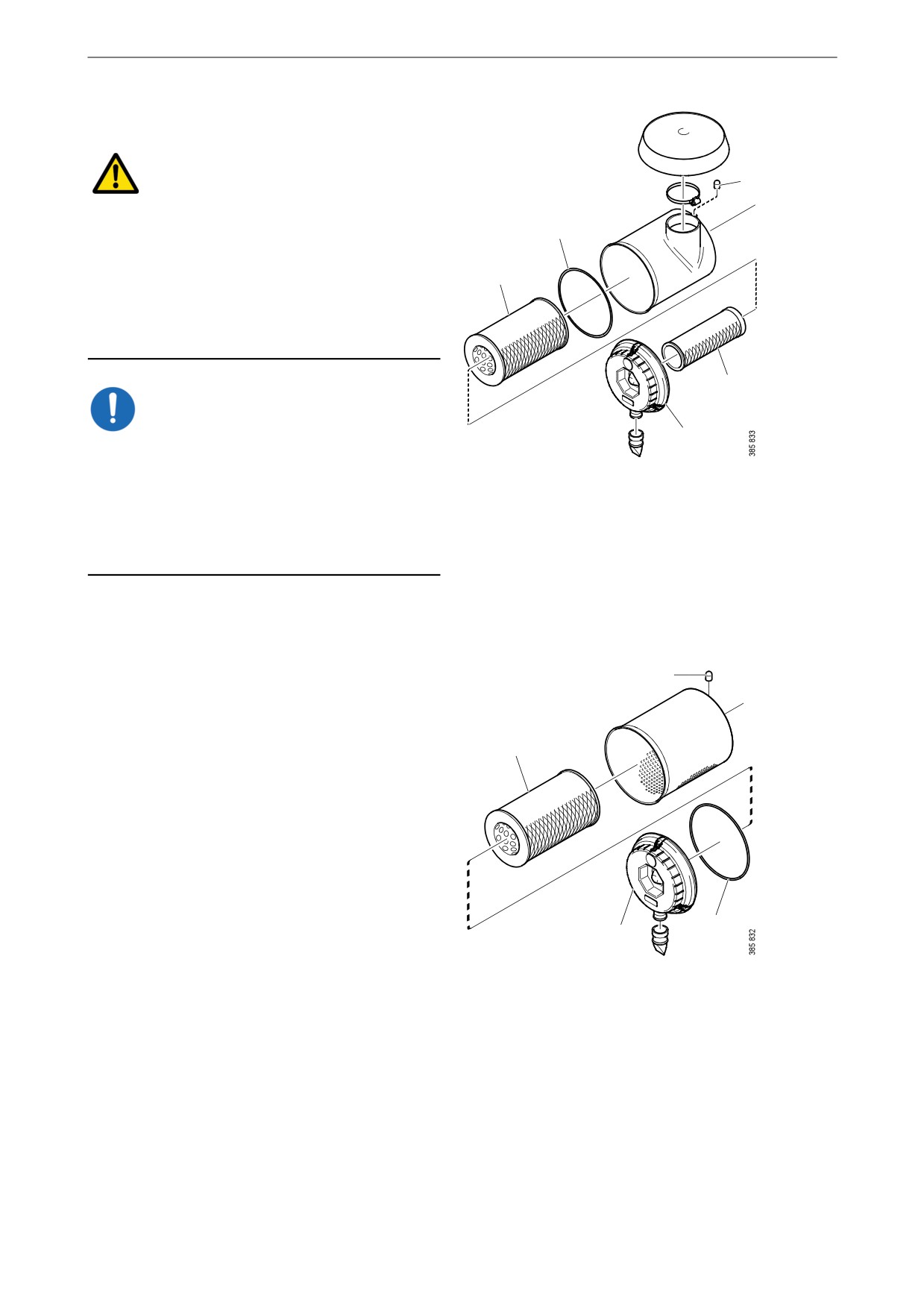

Air cleaner

Air cleaner

WARNING!

3

Never start the engine without the air filter in po-

sition. Without the air filter, there is a risk of dirt

2

being sucked into the engine.

1

The engine turbocharger will continue to rotate

and take in air for a time, even after the engine

has stopped. Therefore, wait for a few minutes

before opening the air cleaner.

4

IMPORTANT!

5

Renew the filter element earlier than the mainte-

nance interval if the vacuum indicator shows red.

1. Air cleaner with safety cartridge.

The filter element must not be cleaned in water

2. Filter element.

or be blown clean with compressed air. There is

3. O-ring.

always a risk that the filter element will be dam-

aged when it is cleaned.

4. Vacuum indicator.

5. Safety cartridge.

6. Cover.

2

1

Reading the vacuum indicator

If the vacuum indicator's red plunger is fully vis-

ible, renew the air cleaner filter element in ac-

3

4

cordance with the following section.

1. Air cleaner without safety cartridge.2. Filter ele-

ment.3. Vacuum indicator.4. O-ring.5. Cover.

32

Air cleaner

Renewing the air cleaner filter

element and safety cartridge

1. Remove the cover from the air cleaner.

2. Renew the filter element.

3. If the air cleaner has a safety cartridge: Re-

move the safety cartridge and fit a new one.

4. Insert a torch into the filter element and

check that the filter paper is free of holes and

cracks.

5. Renew the O-ring if it is damaged or hard.

6. Assemble the air cleaner.

7. Ensure that the O-ring is not outside the edg-

es.

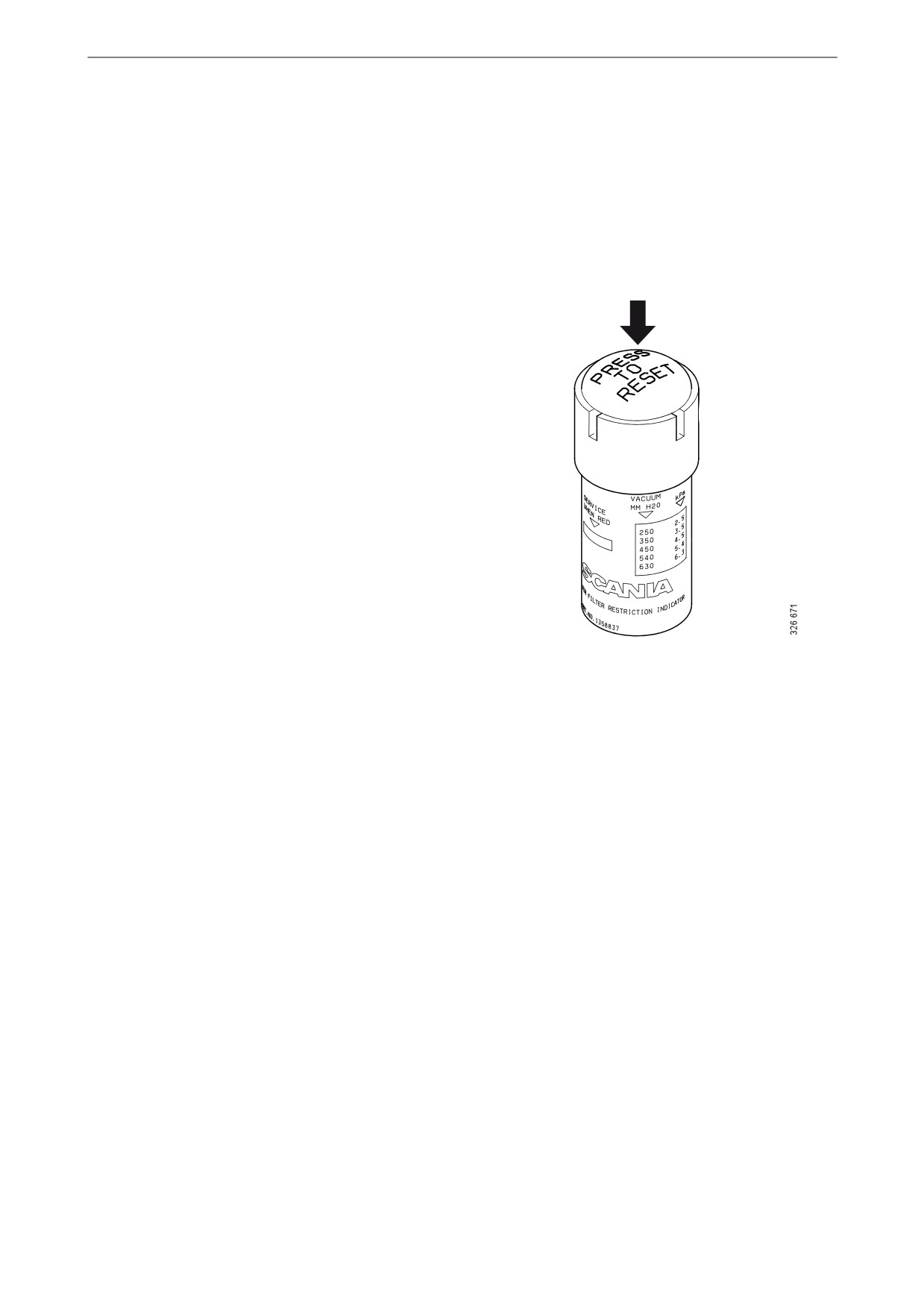

8. Reset the vacuum indicator by pressing in

the button marked in the illustration.

33

Cooling system

Warm climates

Cooling system

In order to retain the corrosion protection and the

higher boiling point, it is essential to use coolant

Coolant

consisting of water mixed with antifreeze and

Note:

corrosion inhibitor (ethylene glycol). This also

applies in countries where the temperature never

The coolant should be changed when the cooling

drops below 0°C (32°C).

system is cleaned: every 6,000 hours or at least

every five years. See Changing the coolant and

cleaning the cooling system.

The coolant recommended by Scania is a mix-

ture of water with antifreeze (ethylene glycol)

and corrosion protection. The coolant has several

characteristics which are important for the oper-

ation of the cooling system:

• Corrosion protection.

• Antifreeze.

• Increases the boiling point.

The coolant should always contain 35-55% by

volume of antifreeze and corrosion inhibitor so

that the coolant properties ensure that the coolant

works correctly.

Note:

Too high a dose of antifreeze and corrosion in-

hibitor will increase the amount of sludge and

blockages accumulating in the radiator. Too low

a concentration can lead to corrosion of the cool-

ing system and ice formation at low tempera-

tures.

34

Cooling system

Antifreeze and corrosion protection

should be used in warm countries where there is

no risk of freezing in the cooling system.

The antifreeze and corrosion protection used in

Scania engines should be of the antifreeze (eth-

ylene glycol) and corrosion protection type.

Part no.

Volume

Volume

Only Scania coolant, or other products tested as

litres

US gallons

antifreeze and corrosion protection for Scania,

2 186 291

5

1.3

may be used in Scania engines. Products that do

2 186 292

20

5.3

not satisfy the requirements for use in a Scania

engine may cause faults in and damage to the

2 186 293

210

55

cooling system. This may lead to the invalidation

2 186 294

1,000

264

of Scania’s warranty for faults and damage

caused by the use of unsuitable coolant.

Scania concentrate

Scania Ready Mix coolant is a pre-mixed coolant

Scania also produces coolant with antifreeze and

consisting of water, antifreeze (ethylene glycol)

corrosion inhibitor in the form of a concentrate.

and corrosion protection. In warm markets

where there is no risk of freezing in the cooling

Part no.

Volume

Volume

system, the concentration of antifreeze and cor-

rosion protection can be lower than in Scania

litres

US gallons

Ready Mix 50/50. Scania Ready Mix 35/65 is

1

894

323

5

1.3

suitable for these markets.

1

894

324

20

5.3

Scania Ready Mix 35/65 contains 35% anti-

1

894

325

210

55

freeze (ethylene glycol) and corrosion protection

1

894

326

1,000

264

and 65% water.

Water

Use only pure fresh water that is free of particles,

sludge and other impurities. If there is uncertain-

ty about the quality of the water, Scania recom-

mends use of Scania ready-mixed coolants. See

the section Recommended Scania products.

Recommended Scania products

Scania Ready Mix 50/50

Scania Ready Mix 50/50 is a ready-mixed cool-

ant containing 50% antifreeze (ethylene glycol)

and corrosion protection and 50% water. It

should be used in cold countries where there is a

risk of freezing in the cooling system.

Part no.

Volume

Volume

litres

US gallons

1 921 955

5

1.3

1 921 956

20

5.3

1 921 957

210

55

1 896 695

1,000

264

Scania Ready Mix 35/65

Scania Ready Mix 35/65 is a ready-mixed cool-

ant containing 35% antifreeze (ethylene glycol)

and corrosion protection and 65% water. It

35

Cooling system

Topping up

Addition of antifreeze and corrosion

inhibitor to water

Coolant must only be topped up with pre-mixed

coolant. The pre-mixed coolant can either be

The coolant should contain 35-55% by volume

concentrate mixed with clean freshwater or pre-

antifreeze (ethylene glycol) and corrosion inhib-

mixed coolant from the factory. Use only pure

itor. The percentage varies depending on the

fresh water that is free of particles, sludge and

need for antifreeze.

other impurities.

A minimum of 35% by volume of Scania anti-

freeze and corrosion protection is needed to pro-

IMPORTANT!

vide sufficient protection against corrosion.

Measure the ethylene glycol content (antifreeze

Containers, which are used for mixing coolant,

and corrosion protection) with a refractometer

must be intended for the purpose and free from

following the instructions in the Checking the

any dirt or contaminants. When the containers

coolant's antifreeze and corrosion protection sec-

not in use they must be kept closed to avoid col-

tion.

lecting dirt and dust.

Risk of freezing

Note:

IMPORTANT!

Within the coolant change interval, coolant may

only be reused if it has been cleaned of dirt,

The engine should not be subjected to heavy

sludge and particles. If the coolant is contaminat-

loads if ice starts to form in the cooling system.

ed with oil or fuel, it must not be reused.

If the coolant starts to freeze, the water in the

coolant starts to crystallise and the ethylene gly-

col content in the coolant increases. If freezing

produces a great increase in the amount of ice,

circulation problems could arise. There is no risk

of damage by freezing if the content of Scania

antifreeze and corrosion inhibitor, or an equiva-

lent mixture of a similar product, is at least 35%

by volume.

Minimal ice formation in the coolant sometimes

causes minor problems without any risk of dam-

age. For example, the auxiliary heater may not

work for up to one hour after the engine has been

started.

36

Cooling system

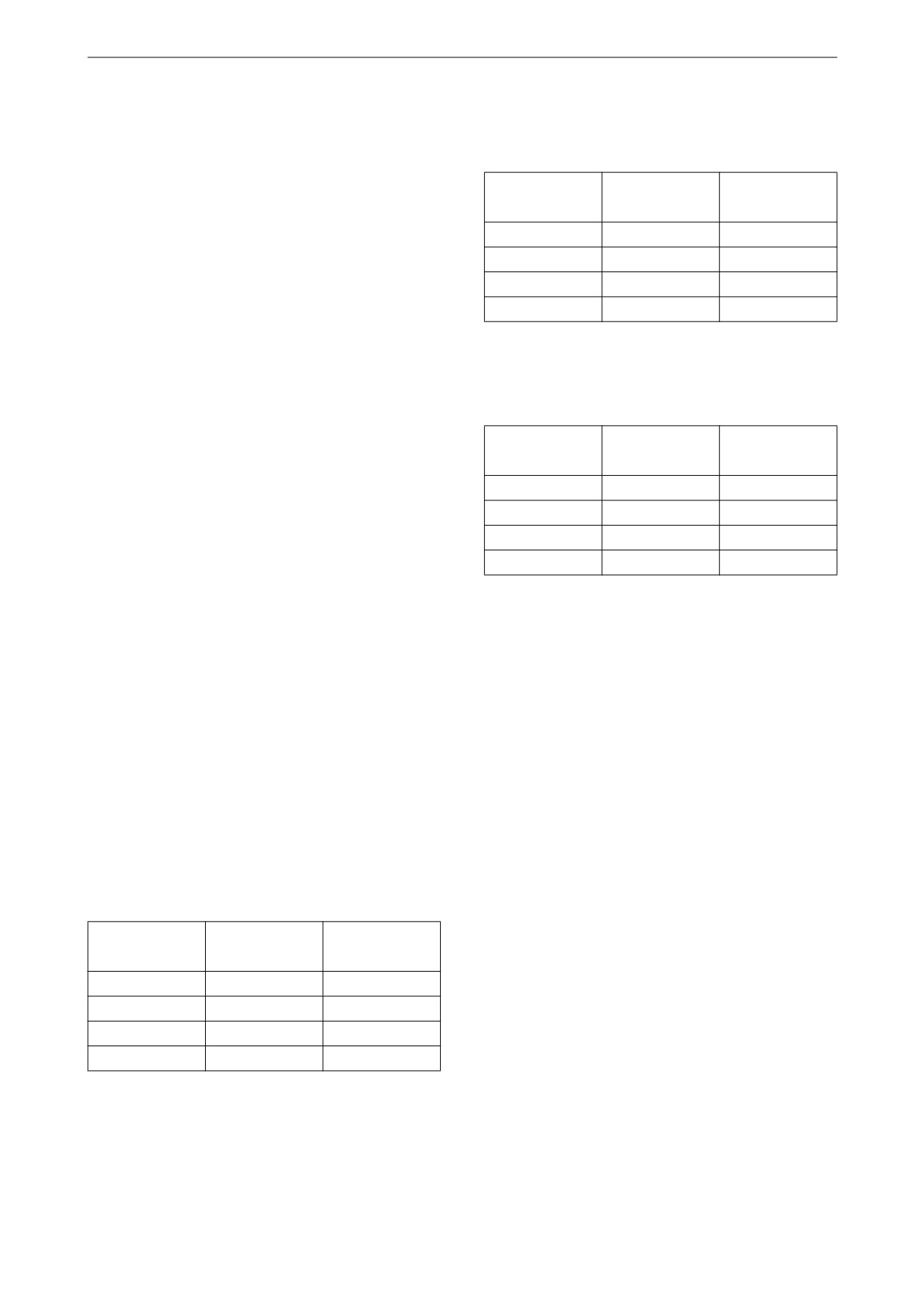

Antifreeze and corrosion protection

concentration table, litres

Freezing point (°C)

-21

-24

-30

-38

-50

Cooling system volume

Ethylene glycol (vol. %)

35

40

45

50

60

(litres)

11

12

14

15

18

30

14

16

18

20

24

40

18

20

23

25

30

50

21

24

27

30

36

60

25

28

32

35

42

70

28

32

36

40

48

80

32

36

41

45

54

90

35

40

45

50

60

100

39

44

50

55

66

110

Ethylene glycol (litres)

42

48

54

60

72

120

46

52

59

65

78

130

49

56

63

70

84

140

53

60

68

75

90

150

56

64

72

80

96

160

60

68

77

85

102

170

63

72

81

90

108

180

67

76

86

95

114

190

70

80

90

100

120

200

37

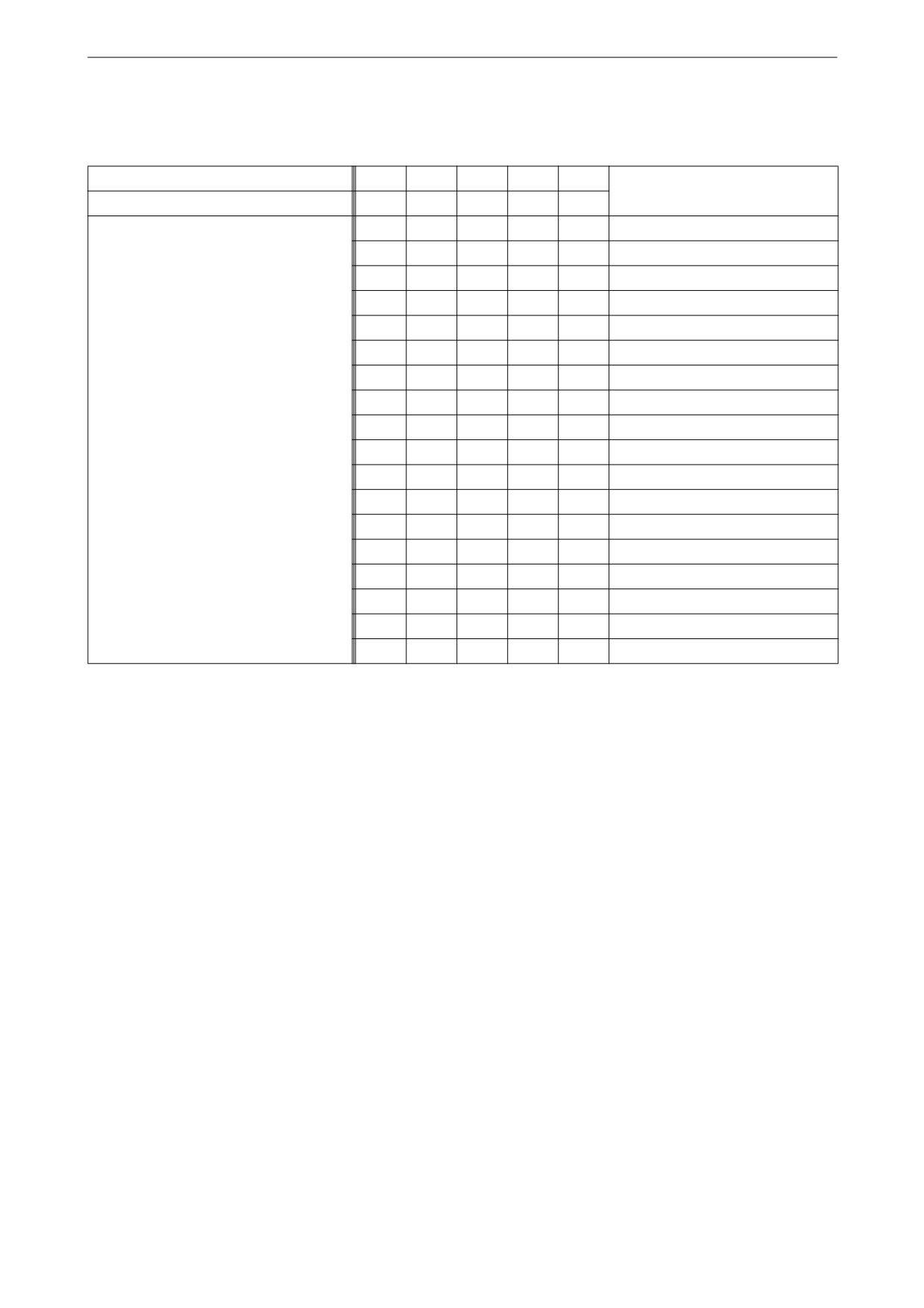

Cooling system

Antifreeze and corrosion protection

concentration table, US gallons

Freezing point (°F)

-6

-11

-22

-36

-58

Cooling system volume

Volume of ethylene glycol (%)

35

40

45

50

60

(US gallons)

2.9

3.2

3.7

4

4.8

7.9

3.7

4.2

4.8

5.3

6.3

10.6

4.8

5.3

6.1

6.6

7.9

13.2

5.5

6.3

7.1

7.9

9.5

15.9

6.6

7.4

8.5

9.2

11.1

18.5

7.4

8.5

9.5

10.6

12.7

21.1

8.5

9.5

10.8

11.9

14.3

23.8

9.2

10.6

11.9

13.2

15.9

26.4

Volume of ethylene glycol (US gal-

10.3

11.6

13.2

14.5

17.4

29.1

lons)

11.1

12.7

14.3

15.9

19

31.7

12.2

13.7

15.6

17.2

20.6

34.3

12.9

14.8

16.6

18.5

22.2

37

14

15.9

18

19.8

23.8

39.6

14.8

16.9

19

21.1

25.4

42.3

15.9

18

20.3

22.5

26.9

44.9

16.6

19

21.4

23.8

28.5

47.6

17.7

20.1

22.7

25.1

30.1

50.2

18.5

21.1

23.8

26.4

31.7

52.8

38

Cooling system

Checking coolant level

WARNING!

Do not open the coolant filler cap in the expan-

sion tank if the engine is hot. Hot coolant and

steam may spray out and cause burns.

If the cap has to be opened do it slowly to release

the pressure before removing the cap. Wear pro-

tective gloves as the coolant is still very hot.

IMPORTANT!

It is not permissible to top up large amounts of

coolant via the expansion tank. Filling via the ex-

pansion tank leads to air locks in the cooling sys-

tem which can lead to e.g. cavitation damage to

the coolant pump shaft seal. If a large amount of

coolant needs to be added, follow the instruc-

tions in the section Filling coolant.

Only pour pre-mixed coolant into the cooling

system.

The following instructions apply to Scania ex-

pansion tanks. For other types of expansion

tanks, follow the manufacturer's instructions.

1. Open the expansion tank cap and check the

coolant level.

- The right coolant level on a cold engine is

even with the lower edge of the filler neck.

- The right coolant level on a hot engine is

approximately 25 mm (1 in) over the low-

er edge of the filler neck.

2. Top up with coolant as necessary.

39

Cooling system

Checking the coolant's anti-

The following rules apply to ethylene glycol-

based coolant:

freeze and corrosion protec-

tion

• The antifreeze and corrosion inhibitor content

must be minimum 35 percent by volume for

Tools

corrosion protection to be sufficient.

• An antifreeze and corrosion protection con-

Designation

Illustration

tent greater than 55 per cent by volume im-

pairs the ability to protect against frost.

Refractometer

• If ice forms in the coolant, there are disrup-

tions initially, but there is no immediate risk

of damage. The engine should not be subject-

ed to heavy loads if ice starts to form.

IMPORTANT!

Use only pure fresh water that is free of particles,

sludge and other impurities.

1. Pour a small amount of coolant into a con-

tainer and check that the coolant is pure and

clear.

2. Change the coolant if it is contaminated or

cloudy.

3. Measure the antifreeze content with a refrac-

tometer.

40

Cooling system

Changing the coolant and

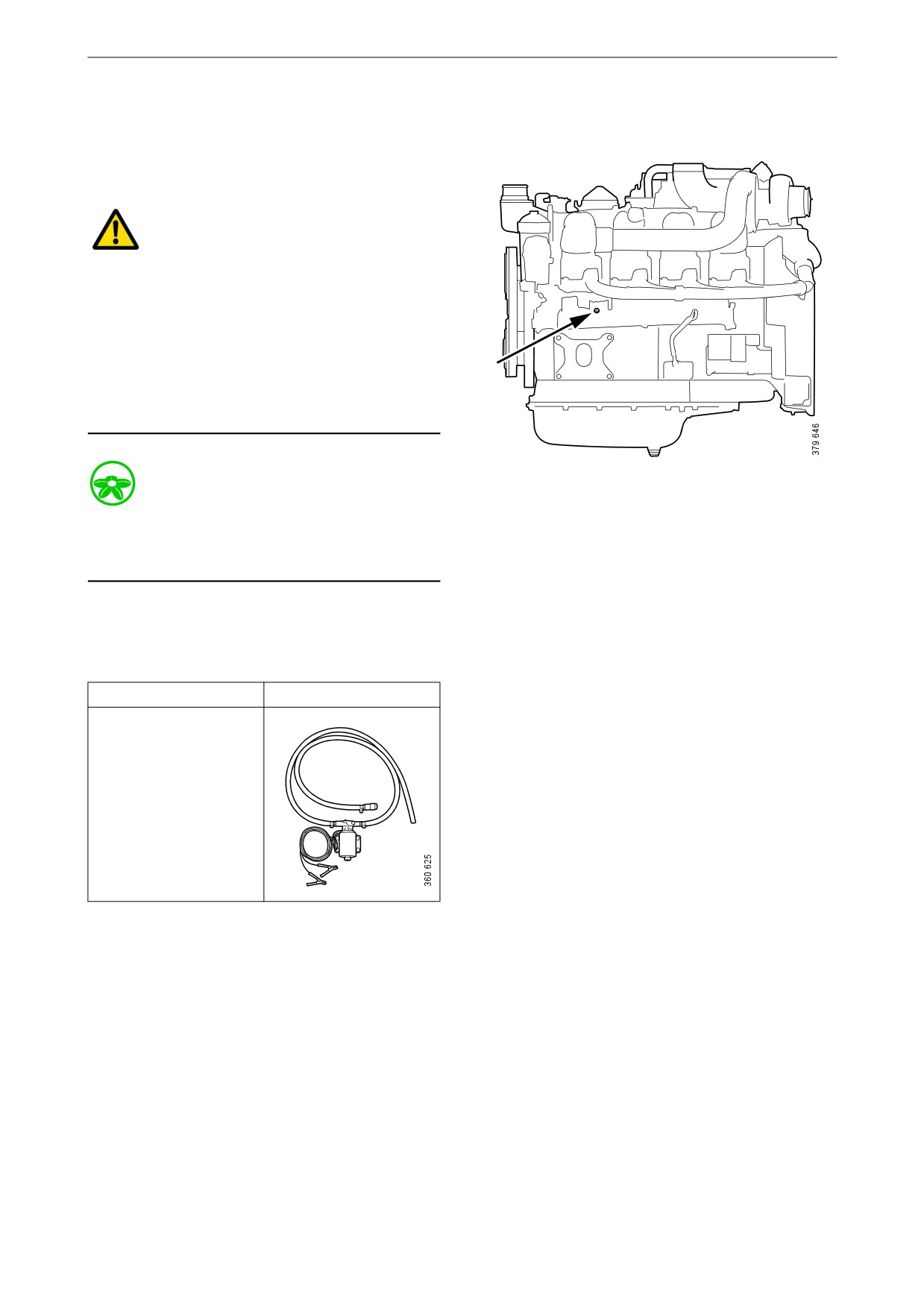

3. Connect the pump to the draining nipple in

the cylinder block. See illustration.

cleaning the cooling system

Draining coolant

WARNING!

Do not open the coolant filler cap in the expan-

sion tank if the engine is hot. Hot coolant and

steam may spray out and cause burns. If the cap

has to be opened do it slowly to release the pres-

sure before removing the cap.

Use protective gloves as coolant can cause irrita-

tion if it comes in contact with the skin. Hot cool-

ant can also cause scalding.

4. Connect the pump’s two cable terminals to

Environment

the battery’s negative and positive terminals.

Make sure that the drainage starts. If the

Use a suitable container. Used coolant must be

drainage does not start: Change the position

disposed of as specified in national and interna-

of the cable terminals.

tional laws and regulations.

Repeat the procedure at the cooling system's

5.

lowest drainage point. The location of the

lowest drainage point on the engine may dif-

Draining coolant with coolant pump

fer depending on engine application.

Special tool

Number, designation

Illustration

2 443 679, coolant

pump

1. Open the expansion tank cap.

2. Position the hose from the coolant pump in

an empty container.

41

Cooling system

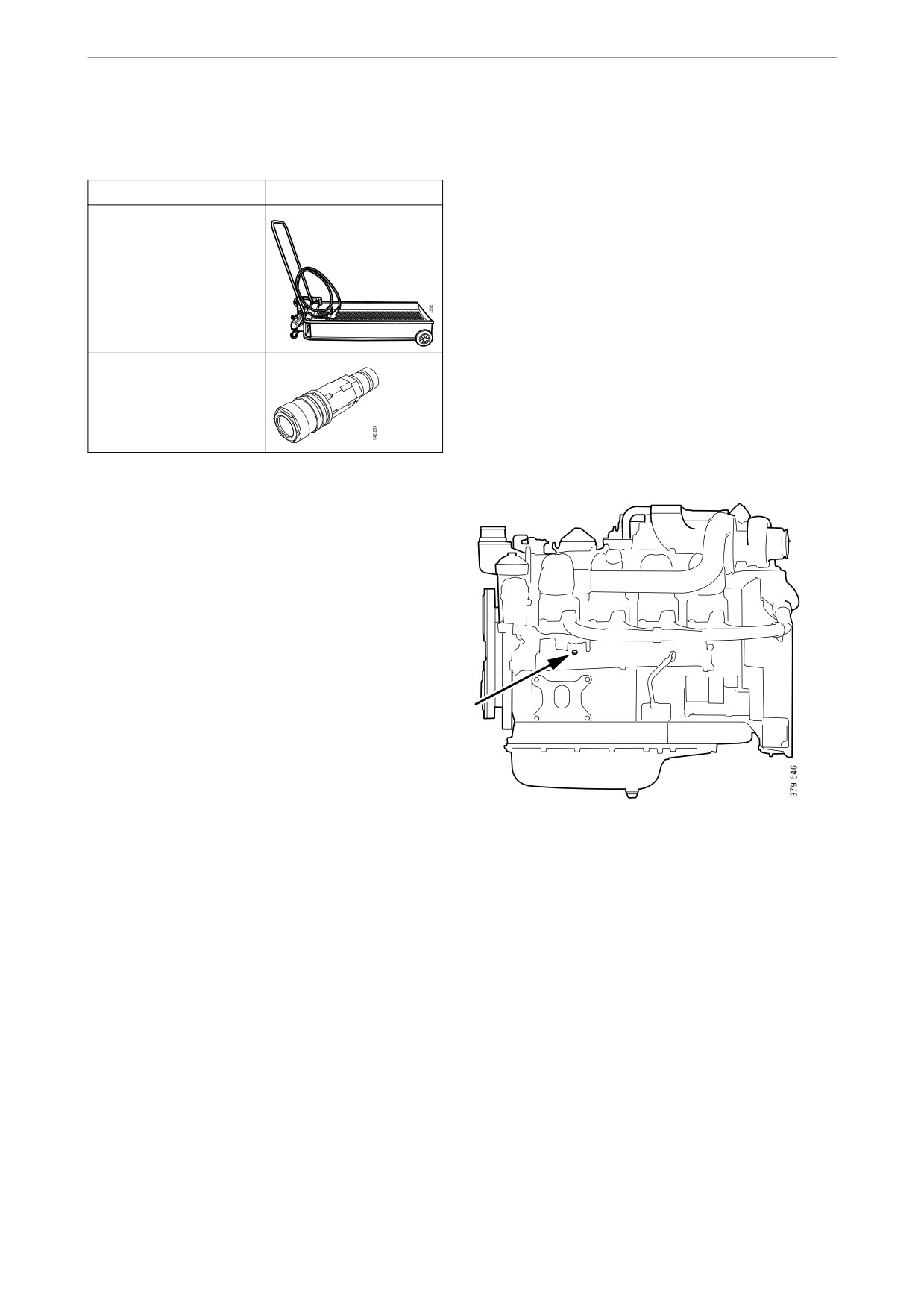

Draining coolant with coolant trolley

Tools

Designation

Illustration

588 540 Coolant trolley

99 301 Adapter

1. Open the expansion tank cap.

2. Position the hose from the coolant trolley in

an empty container.

3. Connect the trolley to the draining nipple in

the cylinder block. See illustration. The

adapter must be used when using the trolley.

4. Drain the coolant.

5. Repeat the procedure at the cooling system's

lowest drainage point. The location of the

lowest drainage point on the engine may dif-

fer depending on engine application.

42

Cooling system

Cleaning the cooling system

Note:

Clean the cooling system more often than speci-

fied in the maintenance interval if necessary.

External: Cleaning the radiator and

charge air cooler

IMPORTANT!

Do not use caustic soda or other alkaline deter-

gent as this could damage the aluminium.

Read the warning text on the detergent packag-

ing.

1. Check that the radiator and the charge air

cooler are not clogged on the air side and that

the cooling fins are not damaged.

2. Carefully scrape away any deposits from the

radiator cooling fins. Use a paraffin-based

engine cleaner if necessary.

3. Carefully straighten bent cooling fins using a

steel brush or the like.

43

Cooling system

Internal: Removing oil and grease

3. Fill the cooling system with clean hot water

mixed with detergent 2 479 017. Detergent

2 479 017 must make up 5-10% (depending

Environment

on the degree of dirt) of the total coolant vol-

ume.

Use a suitable container. Used coolant must be

disposed of as specified in national and interna-

If detergent 2 479 017 is not available, use a

tional laws and regulations.

dishwasher detergent for household dish-

washers that does not foam. Concentration

1%.

Always fit a new thermostat and a new cover to

4. Run the engine until it has reached operating

the expansion tank after cleaning, as the oil in the

temperature for approximately 20-30 min-

cooling system destroys the seals. If the engine is

utes. Remember to switch on the cab heating

equipped with a coolant filter, also renew this fil-

system, if one is installed.

ter.

5. Drain the cooling system.

It may be necessary to wash it multiple times if

6. Fill the cooling system with clean, hot water

the cooling system is very dirty. One cause of

and run the engine for about 20-30 minutes.

contamination can be that oil is lying on top of

7. Repeat steps 3-6 if the cooling system is not

the coolant and collecting high up in the cooling

clean.

system. If several rinses are needed, this is not

necessarily because work has been carried out

8. Drain the water from the cooling system.

incorrectly. Oil residues often need to be rinsed

9. If necessary, clean the expansion tank by de-

repeatedly from the expansion tank and the ex-

taching all hoses and rinsing and cleaning

ternal heating system to be completely clean.

with a degreasing agent and a dishwashing

brush.

Repeated washing is more effective and prefera-

ble to using higher concentrations of detergent

Alternatively, dismantle the expansion tank

(max. 10%) or cleaning for a longer period (max

and clean it with water with 10% of detergent

30 minutes).

2 479 017. Fill the expansion tank with the

mixture, shake it and drain it. Renew the cov-

If only a small amount of dirt has collected in the

er of the expansion tank.

expansion tank after cleaning, one extra rinse

10. Refit the thermostats.

and clean of the expansion tank only is usually

sufficient. There is no need to clean the whole

11. Fill the cooling system with new coolant as

cooling system again.

described in the next section.

12. Check again whether further dirt or oil has

1. Run the engine until it has reached operating

collected in the expansion tank. Decide

temperature and then drain the cooling sys-

whether it it is necessary to carry out another

tem following the previous description.

full cleaning or whether only rinsing or

2. Remove the thermostats.

cleaning of the expansion tank will suffice.

44

Cooling system

Internal: Removing deposits

Filling coolant

These procedures apply when the cooling system

Environment

has been drained and needs to be filled with a

large amount of coolant.

Use a suitable container. Used coolant must be

disposed of as specified in national and interna-

WARNING!

tional laws and regulations.

Use protective gloves as coolant can cause irrita-

1. Run the engine until it has reached operating

tion if it comes in contact with the skin. Hot cool-

temperature and then drain the cooling sys-

ant can also cause scalding.

tem following the previous description.

2. Remove the thermostats.

3. Fill the cooling system with clean, hot water

IMPORTANT!

mixed with radiator detergent which is based

on sulphamic acid and contains dispersing

Mix the coolant as specified in the section head-

agents. Follow the manufacturer's instruc-

ed Coolant.

tions for the concentration and cleaning peri-

Never fill a large amount of cold coolant in a hot

od.

engine. There is great risk of cracks forming in

4. Run the engine for the specified time. Re-

the cylinder block and cylinder heads.

member to switch on the cab heating system,

if one is installed.

Do not start the engine until the correct coolant

level has been obtained. If the engine is started

5. Drain the cooling system.

with an insufficient coolant level, it can damage

6. Fill the cooling system with clean, hot water

the coolant pump shaft seal, which leads to cool-

and run the engine for about 20-30 minutes.

ant leakage.

7. Drain the water from the cooling system.

8. Refit the thermostats.

9. Fill the cooling system with new coolant as

described in the next section.

45

Cooling system

Filling coolant with coolant pump

Special tool

Number, designation

Illustration

2 443 679, coolant

pump

1. Open the expansion tank cap.

2. Connect the coolant pump to the filler nipple

in the cylinder block. See illustration.

3. Connect the pump's 2 cable terminals to the

battery's negative and positive terminal.

Make sure that the filling starts. If the filling

does not start: Change the position of the ca-

ble terminals.

4. Start the engine and run it at idling for

15 minutes.

IMPORTANT!

It is very important that the engine is idling. En-

gine overspeed could damage the coolant pump

shaft seal, which leads to coolant leakage.

5. Switch off the engine and fill with coolant to

the maximum level through the expansion

tank.

Air pockets may still be left in the cooling sys-

tem. These will disappear after the engine has

been operated for a period of time. Therefore, the

coolant may need topping up at a later stage.

46

Cooling system

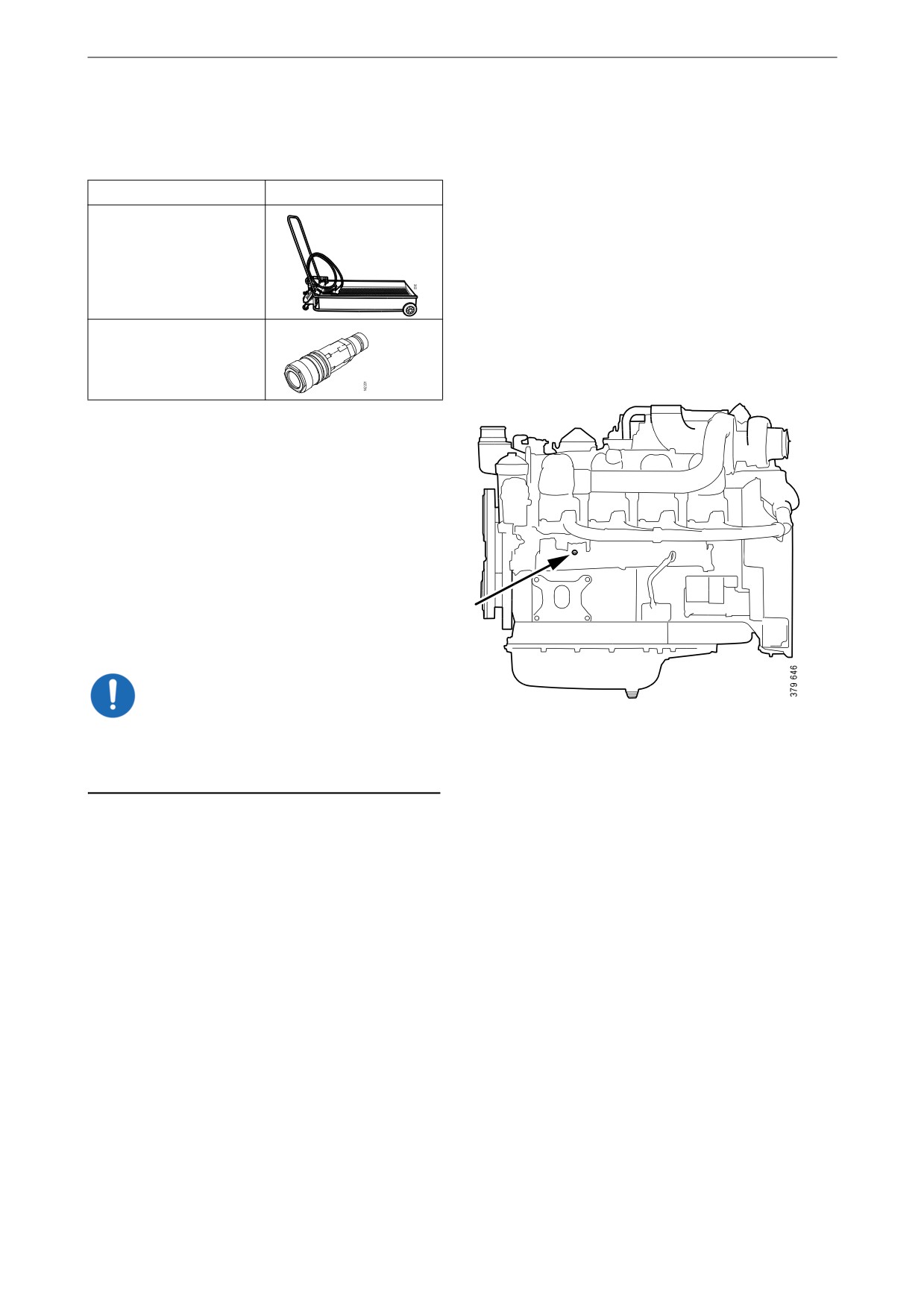

Refilling coolant with coolant trolley

Tools

Designation

Illustration

588 540 Coolant trolley

99 301 Adapter

1. Open the expansion tank cap.

2. Connect the coolant trolley to the filler nip-

ple in the cylinder block. See illustration.

The adapter must be used when using the

trolley.

3. Fill with coolant using coolant trolley to

pump up to the maximum level of the expan-

sion tank.

4. Disconnect the coolant trolley.

5. Start the engine and run it at idling for

15 minutes.

IMPORTANT!

It is very important that the engine is idling. En-

gine overspeed could damage the coolant pump

shaft seal, which leads to coolant leakage.

6. Switch off the engine and fill with coolant to

the maximum level through the expansion

tank.

Air pockets may still be left in the cooling sys-

tem. These will disappear after the engine has

been operated for a period of time. Therefore, the

coolant may need topping up at a later stage.

After filling, it may be good to start the engine

and check that no coolant leakage occurs.

47