Scania DC16 XPI. Industrial engine. Operator’s manual - part 2

Environment and safety

Starter lock

Safety precautions for handling ma-

terials

IMPORTANT!

Fuel and lubricating oil

If the instrument panel is not fitted with a starter

lock, the engine compartment should be locked

WARNING!

to prevent unauthorised personnel from starting

the engine. Alternatively, a lockable master

All fuels and lubricants as well as many chemi-

switch or battery master switch can be used.

cals are flammable. Always follow the instruc-

tions on the relevant packaging.

The work must be carried out on a cold engine.

Starter gas

Fuel leaks and spillage on hot surfaces can cause

fire.

WARNING!

Store used rags and other flammable materials

safely so as to avoid spontaneous combustion.

Never use starter gas or similar agents to help

start the engine. This can cause an explosion in

the intake manifold and possible injury.

Batteries

Running

WARNING!

The batteries contain and form oxyhydrogen gas,

WARNING!

particularly during charging. Oxyhydrogen gas

is flammable and highly explosive.

The engine must not be run in environments

where there is a risk of explosion, as all of the

There must be no smoking, naked flames or

electrical or mechanical components can gener-

sparks near the batteries or the battery compart-

ate sparks.

ment. Incorrect connection of a battery cable or

jump lead can cause a spark, which can cause the

Approaching a running engine always poses a

battery to explode.

safety risk. Parts of the body, clothes or dropped

tools can get caught in rotating parts such as the

fan and cause injury. For personal safety all ro-

tating parts and hot surfaces must be fitted with

guards.

16

Environment and safety

Chemicals

REQUIREMENT!

WARNING!

Use only reductant which fulfils the require-

ments in the Reductant for SCR section.

Most chemicals such as glycol, anti-corrosive

agents, preservative oils and degreasing agents,

are hazardous to health. Some chemicals are also

Safety precautions for maintenance

flammable: preservative oil, for example. Al-

ways follow the safety precautions on the pack-

Switch off the engine

aging.

Store chemicals and other materials which are

WARNING!

hazardous to health in approved and clearly

marked containers, where they are inaccessible

Working with a running engine always poses a

to unauthorised persons.

safety risk. Parts of the body, clothes or dropped

tools can get caught in rotating parts and cause

injury.

Environment

Always switch off the engine before carrying out

Excess and used chemicals must be disposed of

maintenance, unless otherwise indicated.

as specified in national and international laws

and regulations.

Make it impossible to start the engine: Remove

any starter key, or cut the power using the main

power switch or battery master switch and lock

Reductant

them.

Reductant (AdBlue®, DEF, ARLA 32 eller

Fix a warning plate somewhere appropriate,

AUS 32) is used in the reductant tank on engines

showing that work is being carried out on the en-

equipped with an SCR system.

gine.

The reductant is not toxic, but it is still important

Hot surfaces and fluids

to observe the following when working on the re-

ductant circuit:

WARNING!

• If reductant comes in contact with the skin:

Wash with soap and plenty of water.

There is always a risk of sustaining burns when

• If reductant splashes in the eyes: Rinse imme-

an engine is hot. Particularly hot parts are engine

diately using an eye bath and then seek med-

manifolds, turbochargers, oil sumps, as well as

ical attention.

hot coolant and oil in pipes and hoses.

• Change out of clothes which have spills on.

17

Environment and safety

Lubrication system

Fuel system

WARNING!

WARNING!

Hot oil can cause burns and skin irritation. Wear

Maintenance and repairs of injection equipment

protective gloves and goggles when changing

are to be carried out by an authorised Scania

hot oil.

workshop.

Make sure that there is no pressure in the lubri-

Always use Scania spare parts for the fuel and

cation system before starting work on it.

electrical systems. Scania spare parts are de-

signed to minimise the risk of fire and explosion.

Make sure that the oil filler cover is fitted when

starting and running in order to avoid oil escap-

ing.

Environment

Use a suitable container. The fuel collected must

Environment

be disposed of as specified in national and inter-

national laws and regulations.

Used oil must be disposed of as specified in na-

tional and international laws and regulations.

SCR system

Cooling system

IMPORTANT!

WARNING!

Cleanliness is very important when working on

the reductant circuit. Clean thoroughly around

Never open the coolant filler cap when the en-

all parts to be dismantled to prevent dirt from en-

gine is hot. Hot coolant and steam may spray out

tering the system.

and cause burns. If the cap has to be opened do it

slowly to release the pressure before removing

When working on the SCR system, the reductant

the cap. Wear protective gloves as the coolant is

connections may only be lubricated with soapy

still very hot.

water or with distilled water with a 3% urea mix-

ture. Any other types of lubricants may block

Avoid skin contact with coolant as this may

and damage the components in the SCR system.

cause irritation to the skin. Wear protective gog-

gles and gloves when handling coolant.

Reductant causes certain metals to corrode. Al-

ways rinse away reductant spillage on connec-

Ethylene glycol can be fatal if ingested.

tions and other parts with lukewarm water to

prevent corrosion. If reductant seeps into electri-

cal connections or electrical cables, these must

be renewed.

Environment

Used coolant must be disposed of as specified in

national and international laws and regulations.

18

Environment and safety

Electrical system

Batteries

WARNING!

WARNING!

Switch off the engine and switch off the power

The batteries contain highly corrosive sulphuric

by disconnecting the electrical cables to the bat-

acid. Take care to protect your eyes, skin and

tery. External power supplies to extra equipment

clothes when charging or handling batteries.

on the engine must also be disconnected.

Wear protective gloves and goggles.

Always use Scania spare parts for the fuel and

If sulphuric acid comes in contact with the skin:

electrical systems. Scania spare parts are de-

Wash with soap and plenty of water. If it gets in

signed to minimise the risk of fire and explosion.

your eyes: Rinse immediately with plenty of wa-

ter and seek medical attention.

Electric welding

Environment

WARNING!

Used batteries must be disposed of as specified

When carrying out welding work on and near the

in national and international laws and regula-

engine, disconnect the battery and alternator

tions.

leads. Pull out the multi-pin connector for the en-

gine control unit as well.

Before starting

Connect the welding clamp close to the compo-

nent to be welded. The welding clamp must not

WARNING!

be connected to the engine, or so that the current

can cross a bearing.

Ensure that all guards are in place before starting

the engine. Ensure that no tools or other objects

When welding is finished:

have been left on the engine.

1. Connect the alternator and engine control

The air filter must be fitted before starting the en-

unit cables.

gine. Otherwise there is a risk of objects being

2. Connect the batteries.

sucked into the compressor impeller or of injury

if you come into contact with the air filter.

19

Engine data plate

Engine data plate

The engine data plate indicates, in the form of a

code, the engine type, its size and applications. It

also indicates the engine type power range and

the nominal engine speed. The engine EU type

approval for exhaust emissions is indicated un-

der Output, where applicable.

The engine power is stated on a plate which is lo-

cated on the engine control unit. The engine seri-

al number is stamped onto the top of the cylinder

block at the front right.

Made b y

Example: DC16 084A

DC Supercharged diesel engine with air-

Type

DC16 084A

cooled charge air cooler.

Engine No

6950106

16

Displacement in whole dm3

Output.

405-493

kW

2100

r pm.

084

Performance and certification code. The

code indicates, together with the applica-

tion code, the normal gross engine out-

put.

Example of an engine data plate.

A

Code for application. A means for gen-

eral industrial use.

20

Component identification

Component identification

Engine

1

2

7

8

6

5

4

3

2

9

The illustration shows a normal version of a DC16 engine. The engine ordered may have different equipment.

1. Centrifugal oil cleaner

2. Oil filler

3. Oil dipstick

4. Nipples for draining and filling coolant (1 on each side)

5. Fuel filter

6. Oil filter

7. Engine control unit

8. Engine data plate and engine serial number, stamped into the cylinder block

9. Oil plug

Note: The water separating prefilter for the fuel is located between the fuel tank and engine.

21

Component identification

SCR system

The illustration provides an overview of SCR

system components.

6

2

1

3

5

4

7

12

13

8

10

11

9

1. Evaporator or hydrolysis catalytic converter

8. Reductant pump and control unit

2. Pressure line for reductant

9. Coolant hose, return from tank and pump heating

3. Coolant hose for tank and pump heating

10. Exhaust gas temperature sensor

4. NOx sensor with control unit1

11. SCR catalytic converter

5. Coolant valve

12. NOx sensor with control unit

6. Reductant return line

7. Reductant tank

1. DC16 084A/384A/085A/385A only.

22

Starting and running

Starting and running

1

Checks before first start

Before the engine is started for the first time, car-

ry out the maintenance items listed under First

start in the maintenance schedule. Check the fol-

lowing:

• Oil level.

• Coolant.

• Fuel level.

2

• Fluid level in batteries.

• State of battery charge.

• Condition of the drive belt.

• Level in the reductant tank, if the engine is

equipped with an SCR system.

See also Maintenance intervals.

IMPORTANT!

Running the engine without reductant in the re-

3

ductant tank violates emissions legislation and

will damage the SCR system.

Reductant tank

Reductant tanks come in 5 different sizes. The

volumes indicated for each tank are filling vol-

umes.

1. 38 litres (10 US gallons).

4

2. 60 litres (15.8 US gallons).

3. 45 litres (11.9 US gallons).

4. 63 litres (16.6 US gallons).

5. 70 litres (18.5 US gallons).

A filler filter with magnet is fitted in the reduct-

ant tank to prevent the reductant from becoming

contaminated when topping up. It is used when

refuelling at a filling station. A filler filter with-

out a magnet is also supplied for use when filling

manually.

5

23

Starting and running

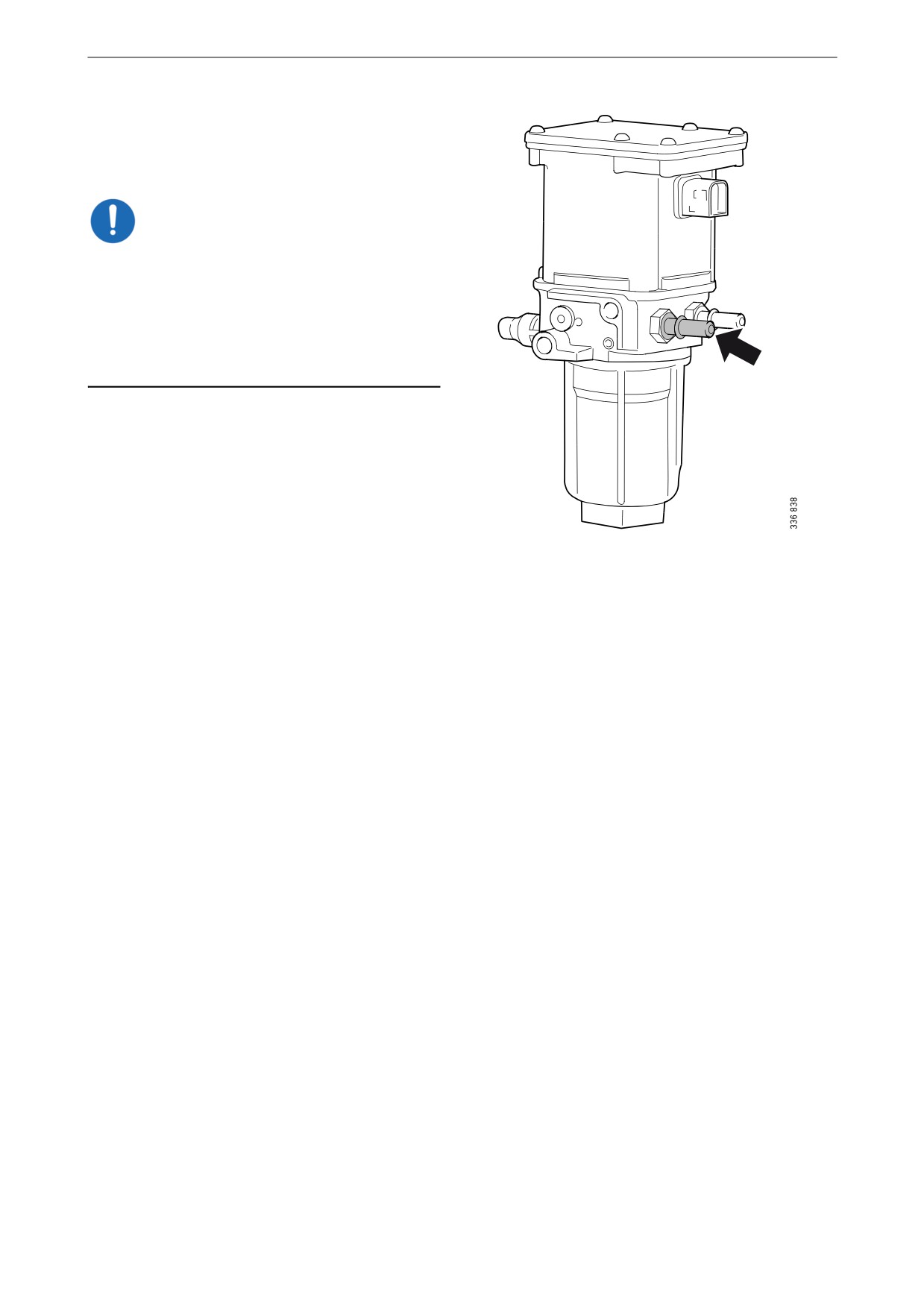

Reductant pump

When the reductant pump is new, the check

valves may need to be slackened.

IMPORTANT!

Blow the reductant pump suction nipple with

compressed air (approx. 6 bar/87 psi) for at least

3 seconds before starting the engine for the first

time.

Start the reductant pump immediately after the

reductant tank has been filled for the first time.

Reductant pump suction nipple.

Checks before running

Carry out daily maintenance as described in the

maintenance schedule prior to operation. See

Maintenance intervals.

24

Starting and running

Starting the engine

Starting at low temperatures and at

high altitudes

Take the local environmental requirements into

WARNING!

account. Use a fuel heater and engine heater to

avoid starting problems and white smoke.

Never use starter gas or similar agents to help

start the engine. This can cause an explosion in

Scania recommends that an engine heater should

the intake manifold and possible injury.

be used if the engine will be used at temperatures

below -10°C (14°F) or at an altitude of more than

Only start the engine in a well ventilated area.

2,000 metres.

When the engine is run in an enclosed space,

there must be effective devices to extract exhaust

A low engine speed and a moderate load on a

gases and crankcase gases.

cold engine limits white smoke, gives better

combustion and warms up the engine more

quickly than warming it up with no load.

IMPORTANT!

Avoid running it longer than necessary at idling

speed.

The starter motor must only be cranked twice for

30 seconds at a time. After that, it must rest for at

Running

least 5 minutes before the next attempt to start it.

Check instruments and warning lamps at regular

intervals.

For environmental reasons the Scania engine has

been developed to be started with a low fuel feed.

Engine speed range

Using unnecessarily large amounts of fuel when

The engine operating speed range is between low

starting the engine always results in emissions of

idling and the nominal engine speed. The nomi-

unburnt fuel.

nal engine speed is indicated on the engine data

plate. Low idling can be set between 500 and 975

1. Open the fuel cock if fitted.

rpm.

2. Disengage the engine.

A slightly higher engine speed than the nominal

3. If the engine has a battery master switch:

engine speed may occur at low or negative load.

Switch on the power by means of the battery

master switch.

Driving at high altitude

4. Start the engine.

When driving at high altitudes engine power is

If the fuel tank has been run dry or if the engine

reduced automatically due to the lower oxygen

has not been used for a long time, bleed the fuel

content in the air. It is then not possible to run the

system. See the section Bleeding the fuel system.

engine at maximum power.

Note:

Driving at an altitude higher than 4,000 metres

above sea level is only permitted if it has first

been approved by Scania.

25

Starting and running

Emission control

The system provides a warning if there are faults

on the SCR system or if the level of reductant in

the reductant tank is too low. In the case of some

faults, for example if doser cooling is not work-

ing, the torque is reduced.

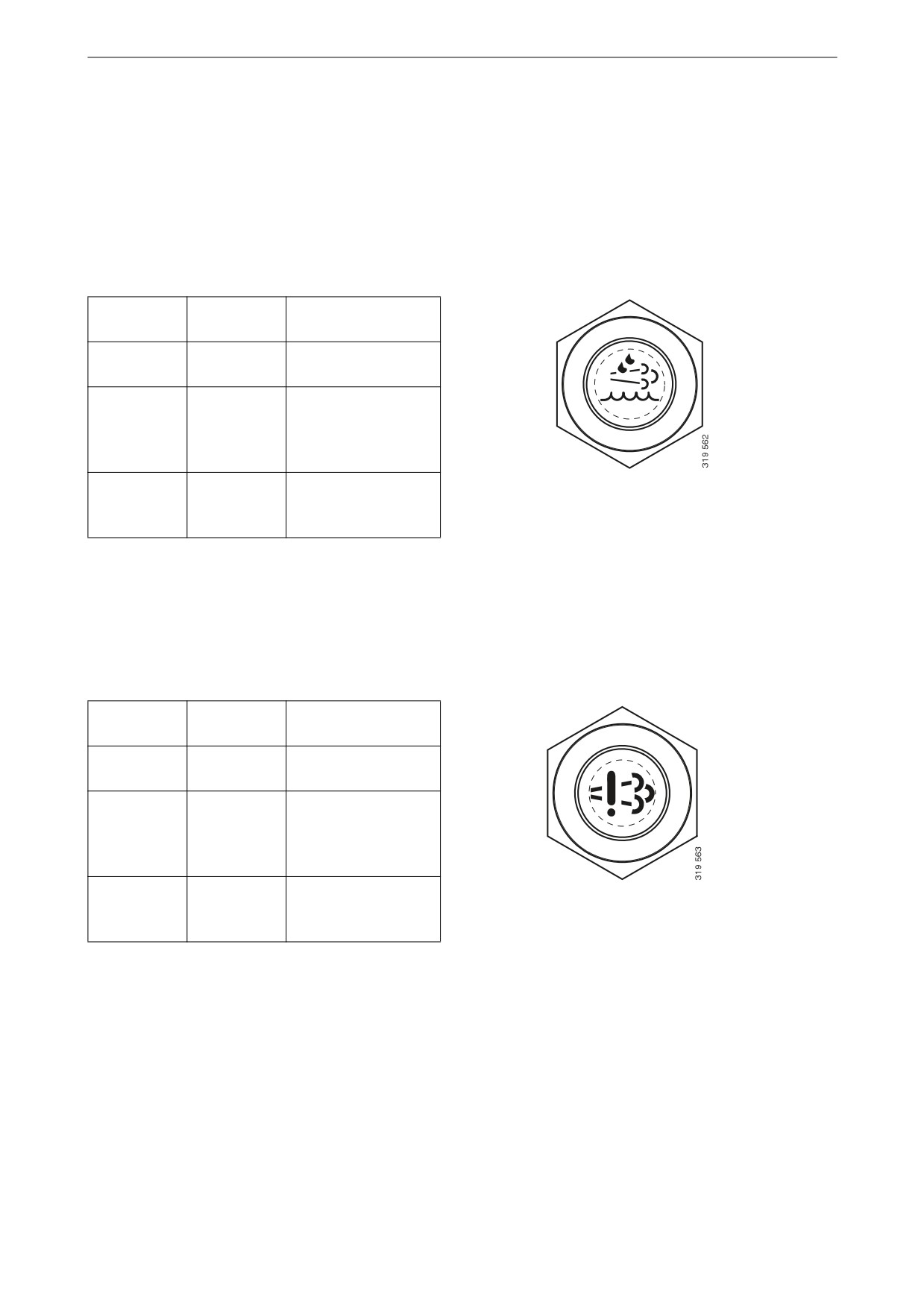

Reaction at low reductant level

Reductant

Warning

Torque reduction1

level

lamp

20%

Constant

light

10%

Flashing

Torque is reduced by

1% per minute to

70% of the highest

torque

0%

Flashing rap-

Torque is reduced to

Symbol for low reductant level.

idly

0% (low idling)

within 2-10 minutes

1. Applies only to engines that are certified according to

Tier 4.

The engine resumes normal torque after reduct-

ant has been filled to a level of at least 20%.

Reaction to fault in SCR system

Time

Warning

Torque reduction1

lamp

Fault detect-

Constant

ed

light

After 30

Flashing

Torque is reduced by

minutes

1% per minute to

70% of the highest

torque

After 4 hours

Flashing rap-

Torque is reduced to

Symbol for fault in SCR system.

idly

0% (low idling)

within 2-10 minutes

1. Applies only to engines that are certified according to

Tier 4.

26

Starting and running

Once the fault has been remedied and the engine

control unit has received an indication that it is

working, torque returns to the normal level.

If a new fault occurs within 40 hours of opera-

tion since the first fault, the warning lamp will

come on. After 30 minutes of operation, the

warning lamp will flash rapidly and torque will

be reduced to 0% (low idling) within 30 minutes.

IMPORTANT!

If the torque has been reduced to 0% (low

idling), the control unit does not detect that the

SCR system is functioning again. A service tech-

nician must then reset the system so that the

torque returns to the normal level.

Note:

The torque reduction applies only to engines that

are certified according to Tier 4.

Some emergency vehicles do not have torque re-

duction.

27

Starting and running

Coolant temperature

Oil pressure

Normal oil pressure during operation is 3-6 bar

IMPORTANT!

(43.5-87 psi). The lowest permitted oil pressure

when idling is 0.7 bar (10.2 psi).

An excessive coolant temperature can cause en-

The engine management system issues an alarm

gine damage.

at the following levels:

• At an engine speed below 1,000 rpm and an

Normal coolant temperature during operation is

oil pressure below 0.7 bar (10.2 psi).

90 to 95°C (194 to 203°F).

• At an engine speed above 1,000 rpm and an

The alarm levels are set in the engine control

oil pressure below 2.5 bar (36.3 psi) for

unit. The default setting for the lowest and high-

longer than 3 seconds.

est limit values for high coolant temperature are

95 °C (203 °F) and 105°C (221°F) respectively.

The following function is standard as alarm for

The following function is standard as alarm for

incorrect oil pressure:

high coolant temperature:

• Alarm and torque reduction by 30%.

• Alarm and torque reduction at the lowest lim-

Depending on the engine configuration, the fol-

it value.

lowing alarm functions may also be available:

Depending on the engine configuration, the fol-

• Alarm only.

lowing alarm functions may also be available:

• Alarm and engine shutdown.

• Alarm only.

• Alarm and engine shutdown override control.

• Alarm and engine shutdown at the highest

limit value.

Note:

• Alarm, torque reduction at the lowest limit

High oil pressure (above 6 bar/87 psi) is normal

value and engine shutdown at the highest lim-

if the engine is cold when started.

it value.

• Alarm and engine shutdown at the highest

limit value with the possibility of engine shut-

Charging indicator lamp

down override control.

If the lamp comes on during operation: Check

• Alarm, torque reduction at the lowest limit

and adjust the alternator drive belt according to

value and engine shutdown at the highest lim-

the instructions in the section Checking the drive

it value, with the possibility of engine shut-

belt.

down override control.

If the charging indicator lamp is still on, this

If run for extended periods under an extremely

could be due to an alternator fault or a fault in the

light load, the engine may have difficulty in

electrical system.

maintaining the coolant temperature. At an in-

creased load the coolant temperature rises to the

normal value.

28

Starting and running

Belt transmission

When the belt transmission is new, it may make

a squeaking noise when running. This noise is

normal and disappears after 50-100 hours of op-

eration. The noise does not affect the service life

of the belt transmission.

Raised idling speed on engines with

SCR and EGR system

If the engine is run without load for an extended

period of time, the SCR system needs to be heat-

ed by raising the idling speed. The function is

called periodic hydrocarbon evaporation and is

used to avoid damaging the SCR catalytic con-

verter.

Periodic hydrocarbon evaporation functions dif-

ferently depending on how the engine is

equipped. A warning is output for all engines if

the engine needs to be warmed up. The warning

is output after approx. eight hours if the engine is

idling without load and the outdoor temperature

is 20°C (68°F). The time is reduced as the out-

door temperature becomes colder.

For some engines, a request for automatic raising

of the idling speed is also output after the warn-

ing. If the request is confirmed, the idling speed

is raised automatically. The function is active for

45 minutes or less and is deactivated automati-

cally. If the request is not confirmed, the engine

is switched off after approx. 45 minutes, if the

engine has been configured with engine shut-

down.

29

Starting and running

Engine shutdown

IMPORTANT!

There is risk of post boiling and of damage to the

turbocharger if the engine is switched off with-

out cooling. The power must not be switched off

before the engine has stopped.

If the engine is equipped with a battery master

switch and an SCR system, the SCR system must

run for a while after the engine has been switched

off to allow it to cool down. During this period

the power must not be cut using the battery mas-

ter switch.

Note:

The battery voltage must remain on for a few

seconds after the 15 voltage is switched off so

that the control units can store the values and

switch to standby mode.

10 prohibited engine shutdowns will cause a

torque reduction (70% of fuel quantity). Reset

the engine by switching it off correctly once.

1. Run the engine without a load for a few min-

utes if it has been run continuously with a

heavy load.

2. Switch off the engine.

30

Starting and running

Checks after running

WARNING!

Block the starting device when working on the

engine. If the engine starts unexpectedly, there is

a serious risk of injury.

There is always a risk of sustaining burns when

an engine is hot. Particularly hot parts are engine

manifolds, turbochargers, oil sumps, as well as

hot coolant and oil in pipes and hoses.

IMPORTANT!

Check the coolant level following the first start.

Top up with coolant as necessary.

1. Check that the power supply has been cut.

2. Top up the fuel tank. Make sure that the filler

cap and the area round the filler opening are

clean to avoid contamination of the fuel.

3. If the engine is equipped with an SCR sys-

tem: Top up the reductant tank. Make sure

that the filler cap and the area round the filler

opening are clean to avoid contamination of

the reductant.

4. If there is a risk of freezing, the cooling sys-

tem must contain enough glycol. See the sec-

tion Risk of freezing.

5. If the temperature is below 0°C (32°F): Pre-

pare for the next start by connecting the en-

gine heater (if fitted).

31