Scania DC09 XPI. Industrial engine. Operator’s manual - part 8

Preparing the engine for storage

9. Detach the fuel pipe at the overflow valve

and connect a return hose to a separate can.

10. Connect and bleed the fuel system.

11. Start the engine and run it at about 1,100 rpm

for 20 minutes.

If the engine has an SCR system and the re-

ductant tank is empty, it is possible to run the

engine for this limited time without damag-

ing the components of the SCR system. This

applies if the engine is run without load.

12. If the engine has an SCR system and the re-

ductant tank is full of reductant: Seal all con-

nections in the SCR system.

13. Remove the rocker covers and lubricate the

valve mechanisms with pushrods and the

valve tappets, as well as the injector mecha-

nism, using a liberal amount of preservative

oil. Refit the rocker covers.

14. Drain the coolant if the engine is not to be

stored with coolant in the system. Plug and

tape all coolant connections if the engine is

to be stored without coolant in the cooling

system.

15. Renew the filter element in the air cleaner.

16. Cover the air intake and exhaust pipe.

17. Spray the outside of the alternator and starter

motor with water-repellent anti-corrosive

oil: CRC 226, LPS1 or equivalent.

18. Spray the outside of bright engine parts, first

with penetrating preservative oil such as

Dinitrol 25B and then with Dinitrol 112 or

the equivalent.

19. Clearly mark the engine with the storage

preparation date, and state that the engine

must not be started or cranked.

112

Preparing the engine for storage

Batteries

WARNING!

Wear protective gloves and protective goggles

when charging and handling batteries. The bat-

teries contain a highly corrosive acid.

Remove the batteries and trickle charge them at

the battery charging station. This does not apply

to batteries specified as maintenance-free by the

manufacturer.

The same applies to short-term storage, even if

the engine has not been prepared for storage as

above.

Storage

After the preparation, the engine should be

stored indoors in a dry location at room temper-

ature. The engine must be packed in packaging

made of VCI plastic to protect against dust, dirt

and moisture.

113

Preparing the engine for storage

When the engine is to be taken into

operation again

1. If the engine is equipped with an SCR sys-

tem: Drain and clean the reductant tank and

fill with new reductant.

2. Remove plugs and tape from the coolant

connections, air intake and exhaust pipe.

3. Fill the cooling system with coolant.

4. Drain the preservative oil.

5. Renew the oil filter and fuel filter.

6. Fill with new engine oil.

7. Remove the rocker covers and lubricate the

valve mechanisms with pushrods and the

valve tappets, as well as the injector mecha-

nism, using a liberal amount of oil. Refit the

rocker covers.

8. Drain the preservative fuel from the fuel

manifold.

9. Connect and bleed the fuel system.

10. Wash off any preservative oil on the outside

using white spirit.

114

Technical data

Technical data

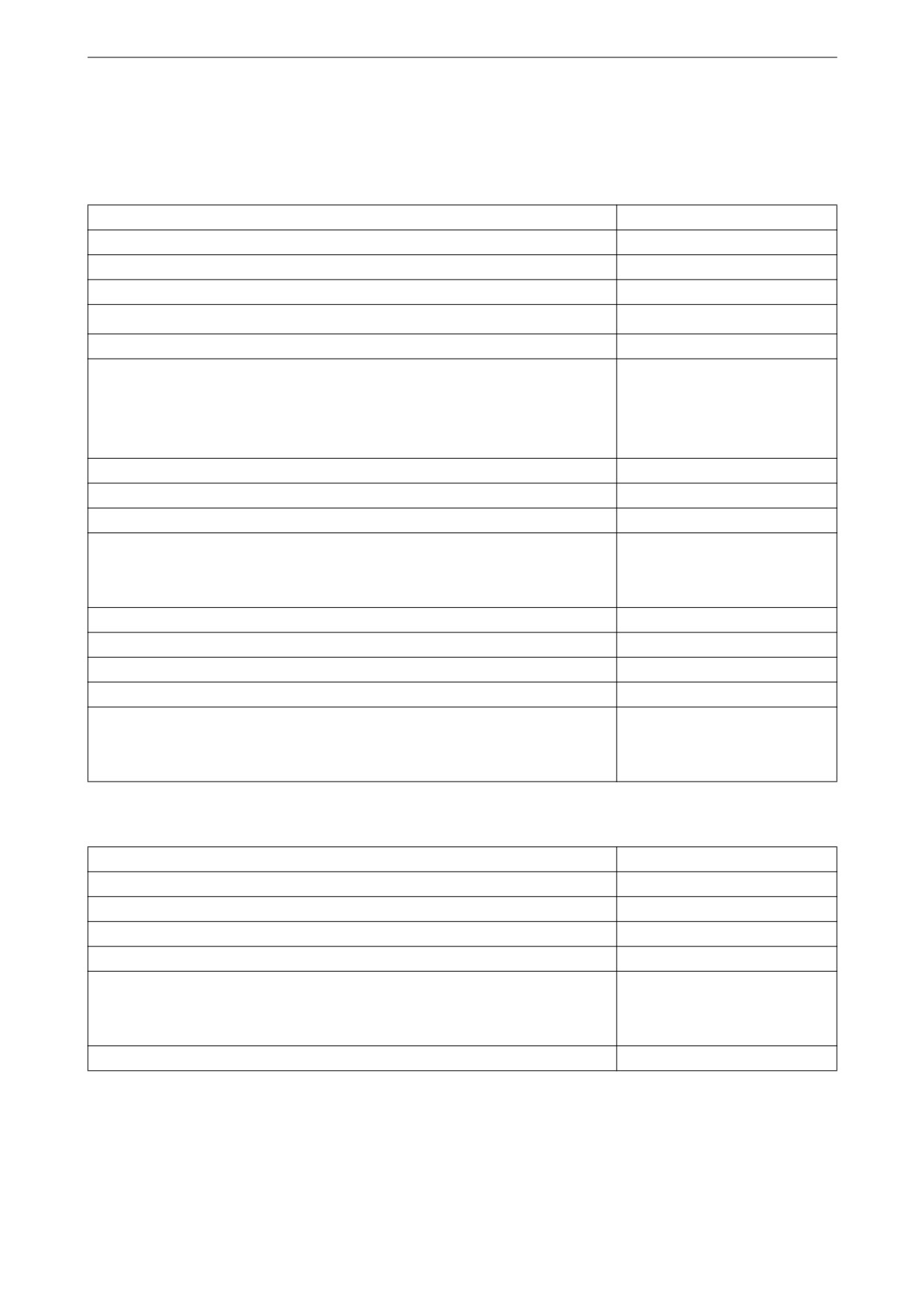

General data

Number of cylinders and configuration

5, straight

Working principle

4-stroke engine

Cylinder diameter (mm/in)

130/5.12

Piston stroke (mm/in)

140/5.51

9.3/567.5

Displacement (dm3/in3)

Firing order

1 - 2 - 4 - 5 - 3

Compression ratio

DC09 076/078/080A

18:1

DC09 084/384/085/385/086/386/087/387/089/389A

17:1

Other engine types

16:1

Engine direction of rotation viewed from rear

Anti-clockwise

Fan direction of rotation viewed from front

Clockwise

Cooling

Coolant

Valve clearances, cold engine

Intake valve (mm/in)

0.45/0.018

Exhaust valve (mm/in)

0.70/0.028

Number of teeth on the flywheel

158

Low idling speed (rpm)

500-975

Maximum full-load speed (rpm)

1,800/2,100

Fuel

Diesel

Approximate weight, without coolant and oil (kg/lb)

DC09 084/384/085/385/086/386/087/387/089/389A

975/2,150

Other engine types

950/2,094

Lubrication system

Oil volume

See Maintenance

Oil cleaning

Centrifugal oil cleaning

Oil cooler

Coolant cooled, full flow

Oil filter

Paper filter from Scania

Interval between oil changes (h)

500

Oil pressure (bar/psi)

Normal with the engine at operating temperature, operating speed

3-6/43.5-87

Minimum permitted at idling speed

0.7/10.2

Crankcase pressure with closed crankcase ventilation (mbar/psi)

-5.4 to 2.0/-0.08 to 0.03

115

Technical data

Intake system

Permissible pressure drop in the intake system with cleaned or new filter

30/0.44

(mbar/psi)

Permissible pressure drop in the intake system with blocked (dirty) filter

65/0.94

(mbar/psi)

Cooling system

Coolant volume, excluding radiator (dm3/US gallons)

DC09 084/085/086/087/089/384/385/386/387/389A

16/4.2

Other engine types

15/4.0

Coolant volume including 1.1 m2 radiator (dm3/US gallons)

DC09 084/085/086/087/089/384/385/386/387/389A

38/10.0

Other engine types

37/9.8

Coolant temperature (°C/°F)

90-95/194-203

Number of thermostats

1

Thermostat opening temperature (°C/°F)

80/176 and 87/189

Fuel system

Injection system

XPI (Extra High Pressure In-

jection)

Engine management system

EMS

Fuel filter

Paper filter from Scania

Water separating prefilter

Paper filter from Scania

Electrical system

Type

1-pin, 24 V, DC

Starter motor, standard equipment

1-pin, 24 V, 6 kW

Alternator, standard equipment

1-pin, 28 V, 100 A

116

Scania Assistance

Scania Assistance

Wherever you are, you can always get assistance

from the Scania service organisation, Scania As-

sistance, all day, every day of the year.

Always call the contact for your country.

Country

Tel

Country

Tel

Austria

+43 1 256 44 11

Latvia

+371 29 44 24 24

America

+1 (0) 800 272 2642

Lithuania

+46 8 52 24 24 24

America

1 800 272 2642

Luxembourg

+32 2 264 00 00

Argentina

800 999 722 642

Malaysia

1800 08 8500

Australia

+611300722642

Malaysia

+6035590907

Belgium

+32 2 264 00 00

Mexico

+543327451092

Botswana

+267 72 102 591

Morocco

+3222640000

Brazil

+8000194224

Namibia

+264634461352

Bulgaria

+359 88 666 0001

Netherlands

+31 76 52 54 111

Chile

188 800 722 642

Norway

+47 223 217 00

Colombia

+1800184548

Peru

0800-51-727

Czech Republic

+420 225 020 225

Peru

(01)512-1877

Denmark

+45 333 270 44

Poland

+48 22 331 22 33

Estonia

Tallinn: +372 5153 388

Portugal

+34 91 678 9247

Estonia

Tartu: +372 5126 333

Romania

+40 723 27 27 26

Estonia

Pämu: +372 5071 477

Russia

+7(495) 925 77 75

Estonia

Rakvere: +372 5074 655

Singapore

+6565917180

Finland

+358 10 555 24

Slovakia

+421 903 722 048

France

+33 2 414 132 32

South Africa

0 800 005 798

Germany

+49 261 887 8888

South Africa

+27 11 226 5005

Great Britain

0 800 800 660

Spain

+34 91 678 80 58

Great Britain

+441274301260

Sweden

+46 42 100 100

Hungary

+36 209 727 197

Switzerland

+41 800 55 24 00

Ireland

+353 71 963 4000

Thailand

+66819397525

Italy

+39046 1996222

Thailand

+1800 019 88

Latvia

+46 8 52 24 24 24

Uruguay

0 800 835 1

Other countries: +46 8 52 24 24 24

Note:

Calls will be recorded for training purposes.

117

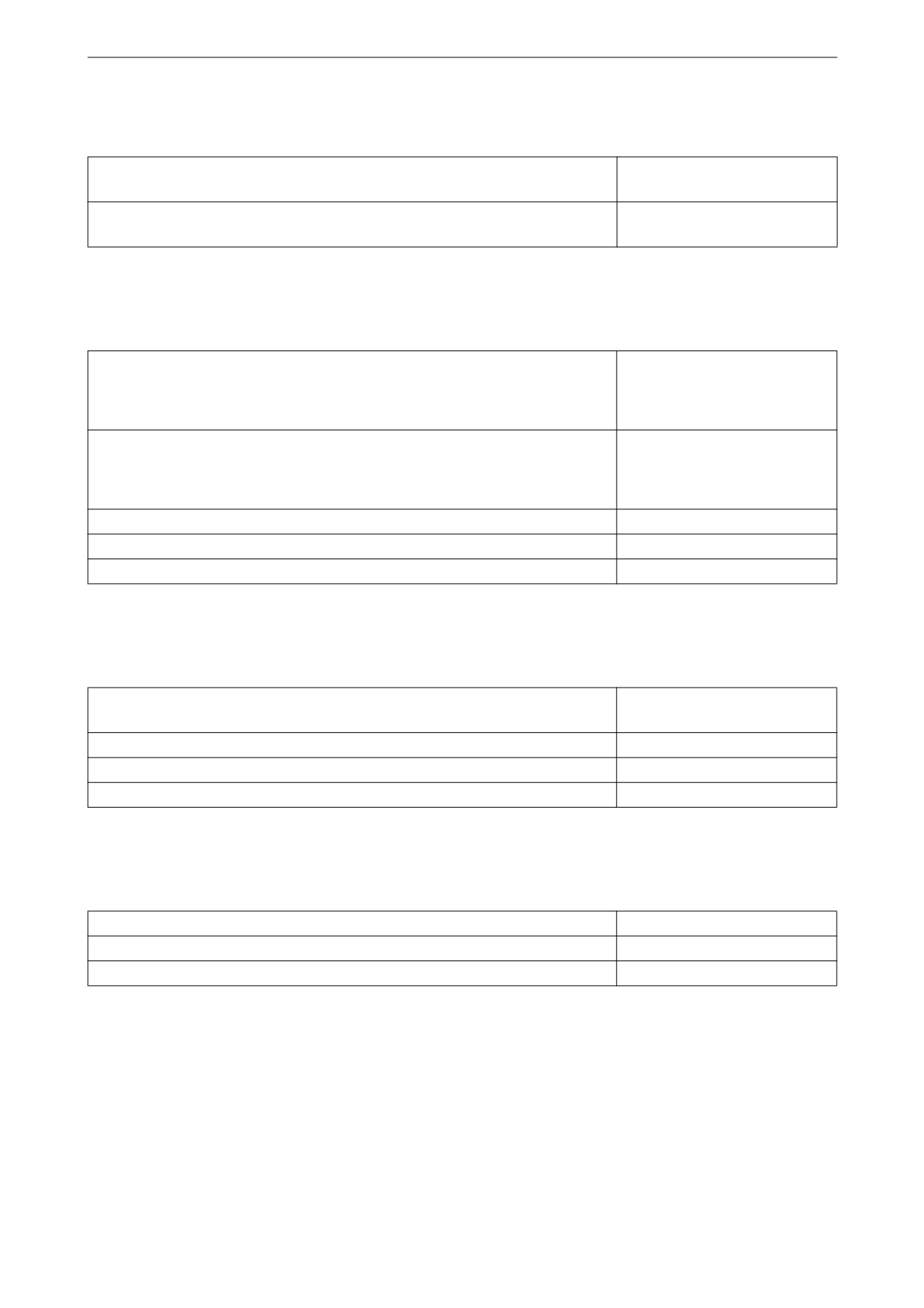

General tightening torques for screw joints

General tightening torques

for screw joints

Hexagon screws, hexagon

socket screws, Torx screws,

hexagon nuts

Metric thread. Strength class 8.8/8.

Tightening torque

Thread

Nm

Lb-ft

M4

2.9

21

M5

6

4

M6

9.5

7

M8

24

18

M10

47

35

M12

84

62

M14

135

100

M16

210

155

M18

290

214

M20

420

310

M22

580

428

M24

730

538

Flange screws with hexago-

nal head and hexagonal

flange nuts

Metric thread. Strength class 8.8/8.

Tightening torque

Thread

Nm

Lb-ft

M5

6.7

5

M6

10.2

8

M8

26

19

M10

50

37

M12

92

38

M14

149

110

M16

184

136

118

General tightening torques for screw joints

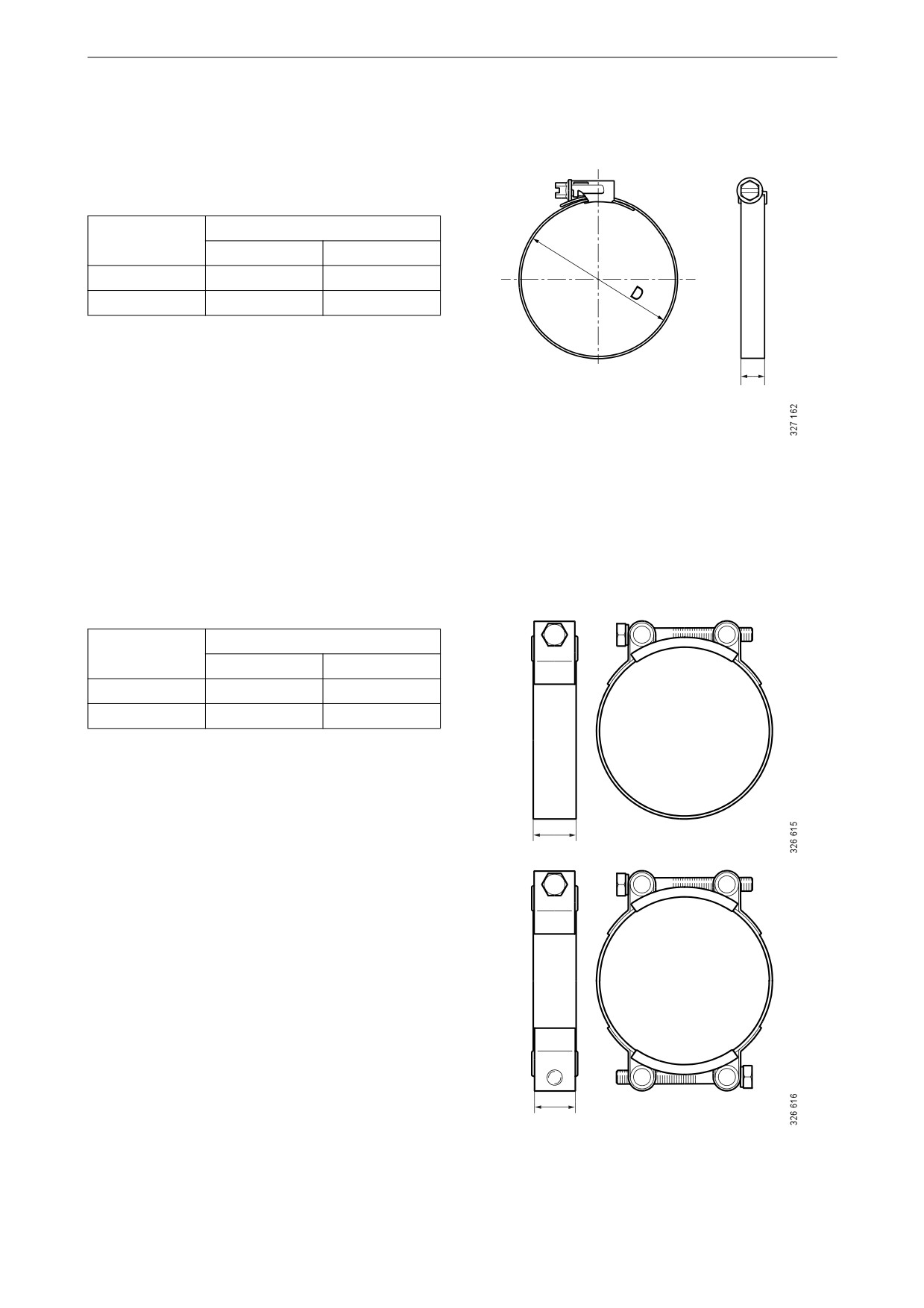

Hose clamps

Specifications in the tables show tightening

torque when tightening by hand.

A = width

Tightening torque

(mm)

Nm

Lb-ft

7.5-9

1.5

1

12

5

4

A

Tightening torque for new unfitted hose clamp is

max 1 Nm (0.7 lb-ft).

A = width

Tightening torque

(mm)

Nm

Lb-ft

20

10

7

25

20

15

A

A

119