Scania DI12, DC12. Industrial engine. Operator’s manual - part 2

17

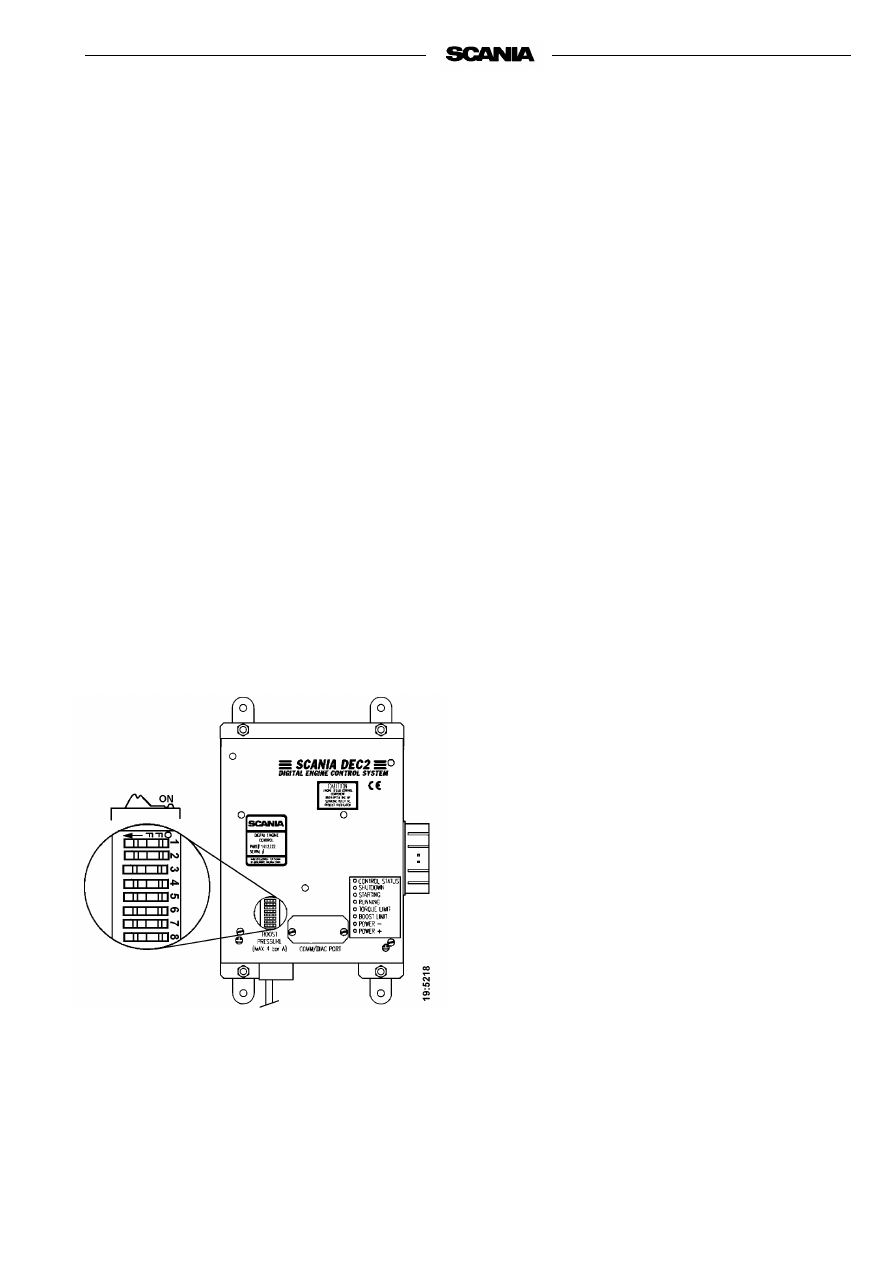

Changing functions using the DIP

switches in the control unit

There are 8 DIP switches in the control unit under the

round black rubber cover.

These switches shall be in the ON position to obtain

normal functions according to the operating program.

However, for single-speed engines, the normal

position of DIP switches 6, 7, and 8 may also be OFF

Shutdown at threshold values for low oil pressure and

high coolant temperature can be selected by setting

DIP switch 4 to OFF

With DIP switch 4 in position ON, Power- indication

is obtained for these threshold values. Engine output

reduction (LOP) can be selected to prevent damage to

the engine. Changes to the program must only be

performed by authorized personnel.

Note:

Do not operate the engine with a Power-

indication except for in emergencies.

Readout of fault codes

Note:

If the engine has stopped or lost power but

the main indicator lamp is out and neither

POWER- nor SHUTDOWN are on, the fault

is outside the control unit detection range.

Probable causes: fuel shortage, temporary

overload, mechanical fault.

- Activate the lamp test/fault code switch. In

Scania electrical equipment the main indicator

lamp is located in this switch on the main supply

box.

- All LEDs will then come on for 2 seconds to

indicate that they are intact and in working order.

This also applies to the main indicator lamp in the

main supply box and the instrument panel

.

Make

a note of any LED that is defective.

- All LEDs will then be out for approximately 4

seconds.

- Following this, a fault code will be indicated on

one of the LEDs for 2 seconds. Note which LED

it is.

- The control unit then resumes the operating mode

automatically.

- After having made a note of the fault code, reset

the lamp test/fault code switch and reset the

control unit by turning off its power supply

momentarily.

- The most probable cause of the fault can then be

found in the trouble shooting schedule on the next

page.

- When the fault or faults have been rectified the

engine can be restarted.

- If the control system continues to indicate a fault

by way of the main indicator lamp, further faults

may have been recorded. The fault code readout

must then be repeated as per above since the

system can only display one fault code at a time.

- The fault(s) will be stored in a special memory in

the control unit along with information about the

operating time when it(they) occurred. Stored

faults can be accessed and erased by authorised

service personnel.