Scania DI9, DC9 with DEC2. Industrial engine. Operator’s manual - part 4

49

Alternative 2

- Set No. 1 cylinder to TDC by turning the engine in its direction of

rotation until all four valves are closed.

- Adjust all valves for No. 1 cylinder. Correct valve clearances are

indicated on the instruction plate on one of the rocker covers.

- Repeat this procedure with the other cylinders in the order

5 - 3 - 6 - 2 - 4 (firing order) by turning the engine 1/3 revolution in its

direction of rotation between each adjustment.

Note:

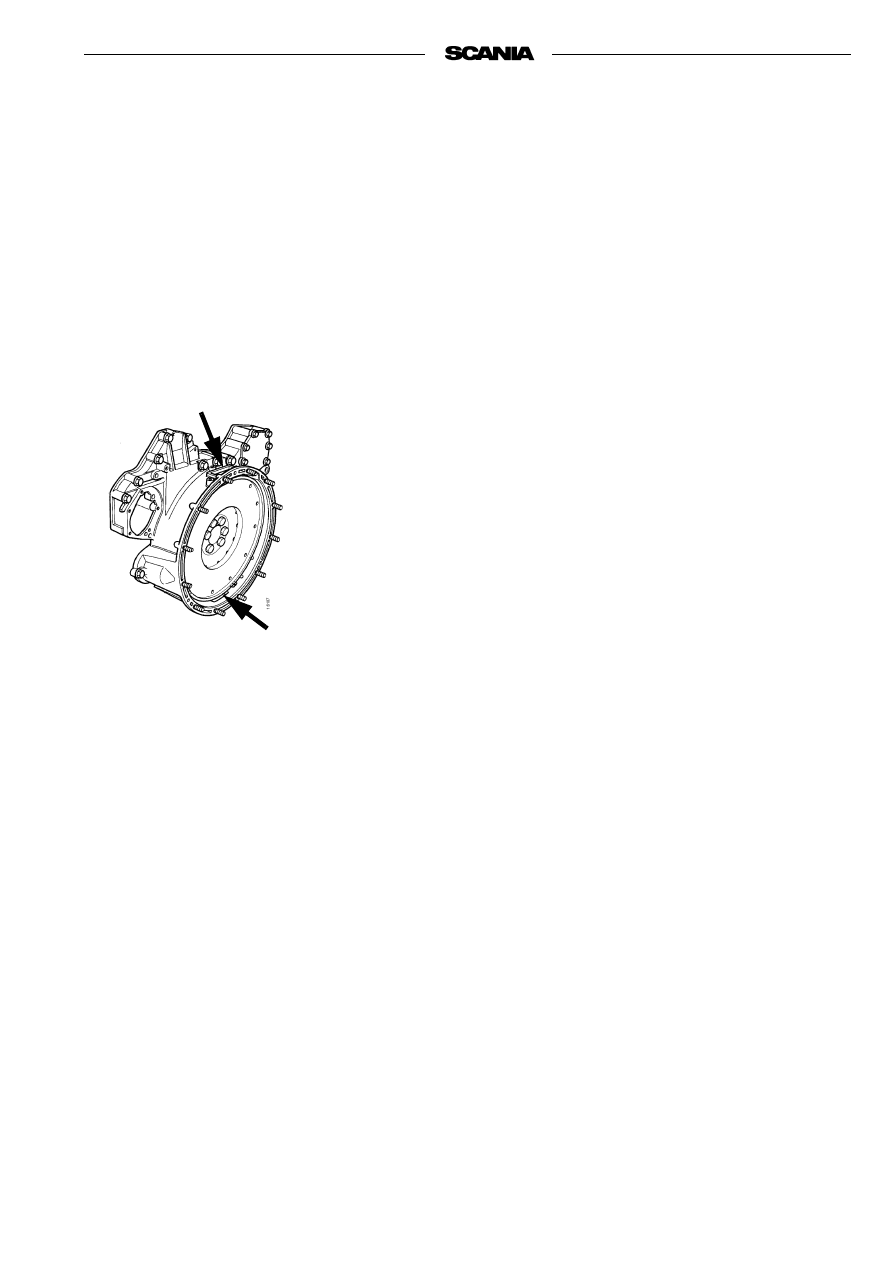

Readings can be taken from the

flywheel through covers in the

flywheel housing either from

above or underneath depending

on access when fitting.

It says up or down on the flywheel

Both covers are fitted with a cover

at delivery.

Covers for reading

on the flywheel housing