SCANIA INDUSTRIAL ENGINES (specification) - part 30

SCANIA industrial engines

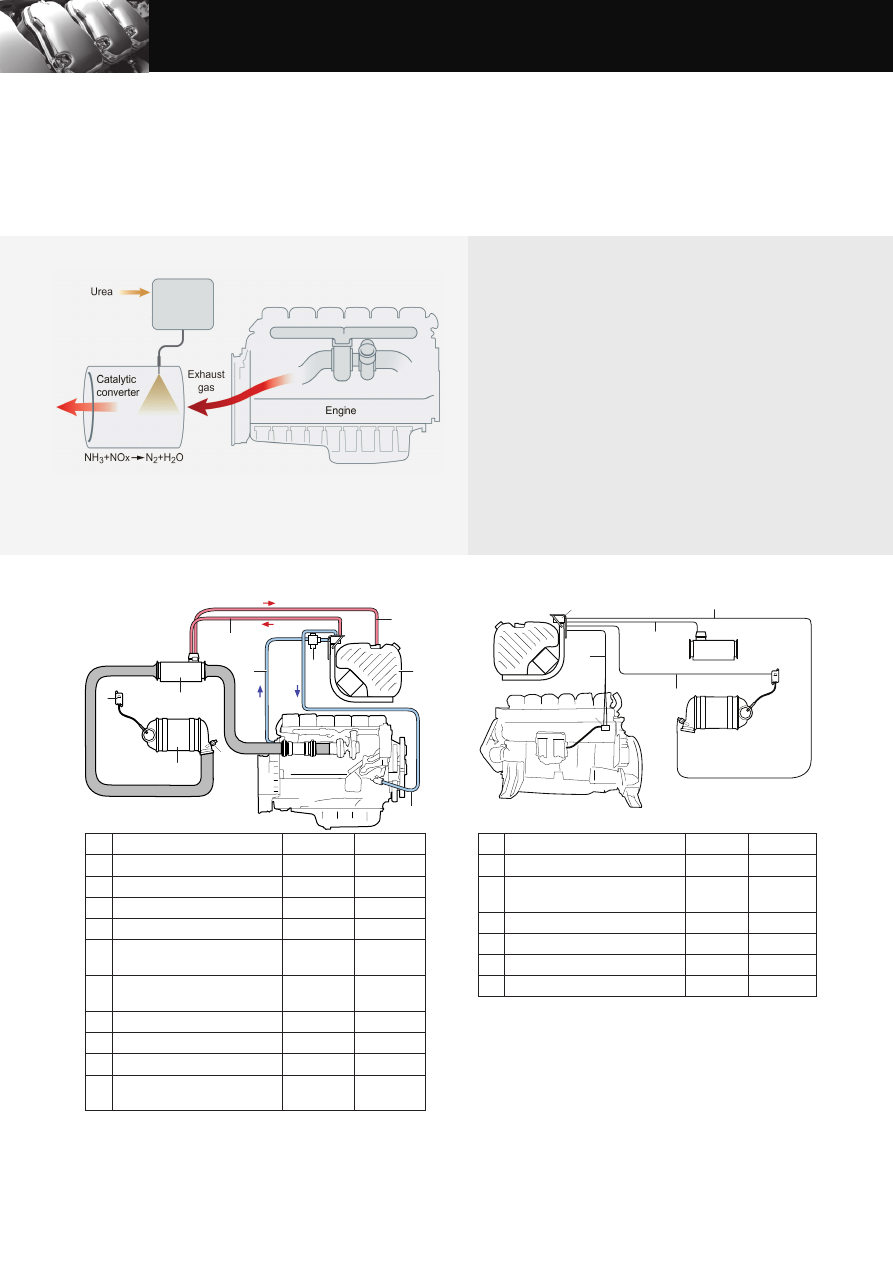

sCr system

us tier 4i, eu stage iiiB

SCR (Selective Catalytic Reduction) technology is used on Scania’s engines

for Stage IIIB and Tier 4i to reduce the NO

X

content in the exhaust gases.

A chemical process is started by injecting reductant, a urea and water

mixture, into the exhaust gas stream. During injection the water evaporates

and the urea breaks down to form ammonia. The ammonia then reacts

with the nitrogen gases in the catalytic converter and forms harmless

products such as nitrogen gas and water. Through the use of SCR the

exhaust gases are purged of poisonous levels of NO

X

in the best possible

way. Scania is making use of a system that is carefully developed and

tested in our own laboratory.

The reductant tank holds 38 or 60 litres and is heated by the engine’s

cooling system in order to avoid freezing of the urea solution, urea

freezes at -11°C. The reductant tank and a pump module are delivered

as a unit which is fi tted to brackets for an easy installation. The Scania

system contains all mechanical and electrical parts needed except from

the exhaust piping which is to be adapted according to the customers

installation.

Mechanical system

Standard

Optional

1

Reductant tank and pump module

38 l

60 l

2

Reductant fl uid return line

2 m

3.5 m

3

Coolant valve

–

4

Reductant pressure line

2 m

3.5 m

5

Coolant hose for tank and pump

heating

–

–

6

Evaporator module / Hydrolysis

catalyst with reductant doser

–

7

NO

X

sensor with control unit

–

8

SCR catalyst

–

9

Temperature sensor

–

10

Coolant hose, return from tank and

pump heating

–

–

Mechanical system

Electric system

Electric system

Standard

Optional

1

Customer interface, SCR system

–

2

Pipe network between engine and

SCR control unit

3 m

6 m

3

Electrical interface, SCR system

–

4

Temperature sensor electrical cable

3 m

6 m, 9 m

5

Reductant doser electrical cable

3 m

6 m

6

NO

X

sensor electrical cable

3 m

6 m

The principle for Scania SCR system

This specifi cation may be revised without notice.

6

1

9

2

8

3

7

5

10

4

1:7058

3

1

2

6

5

4

1:7059