содержание .. 6 7 8 9 ..

Scania 16 litre engine. Work Description - part 8

0101w14b.mkr

©

29

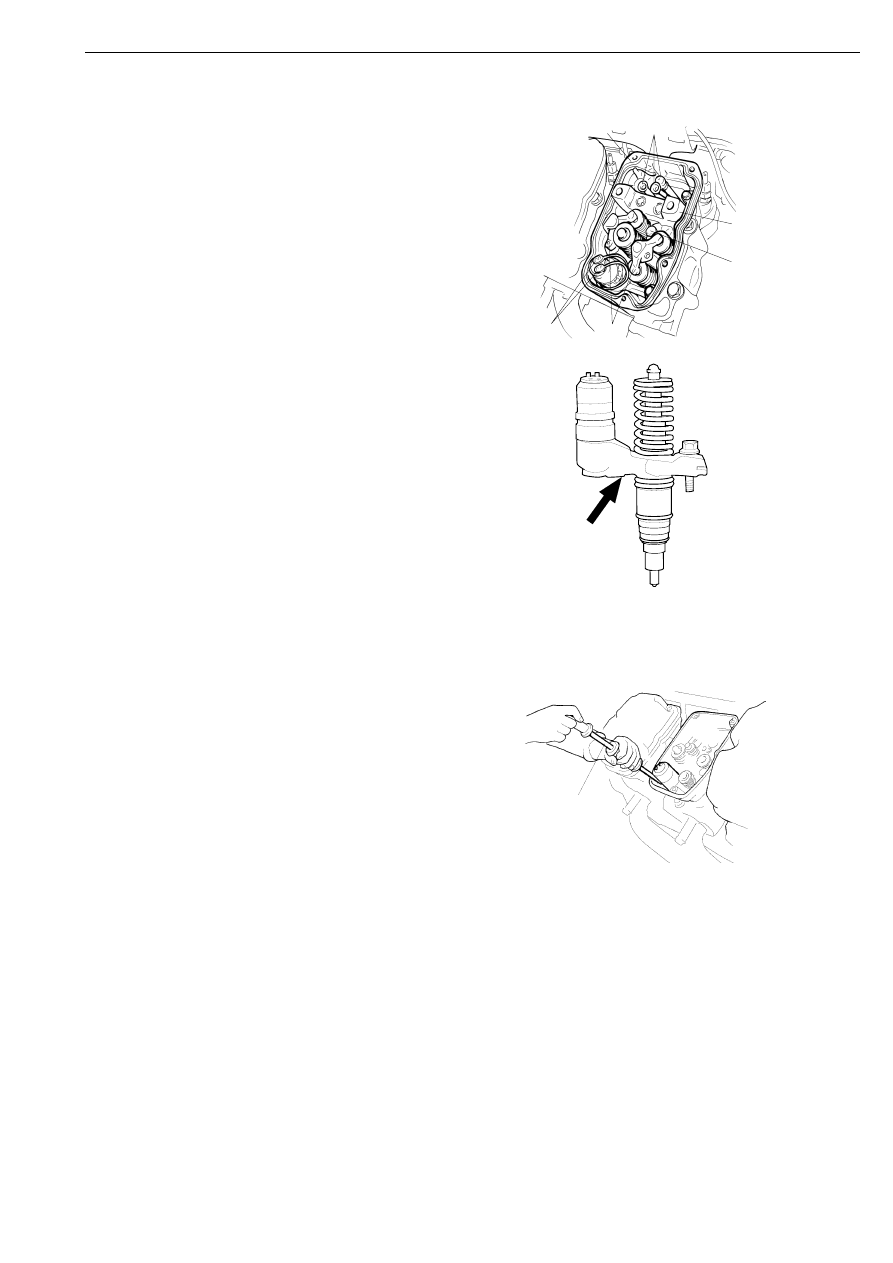

14 Remove the bearing bracket.

15 Remove the pushrods.

Note: The pushrod for the unit injector is

secured with a retaining ring. Jiggle and pull

carefully on the pushrod to loosen it.

16 Remove the valve yokes.

17 Disconnect the cables on the unit injector

and pull them out through the opening in the

rocker cover.

18 Remove the lower rocker cover.

19 Remove the screw for the fork clamp

holding the unit injector in place.

Note: Do not lift the unit injector by its spring,

the spring can come loose.

20 Turn the unit injectors clockwise until they

stop. Place the slide hammer 87 596

between the solenoid valve and the edge of

the lower rocker cover as illustrated.

114 728

17

14

18

15

16

19

Place the slide hammer as indicated by the

arrow

116 271

111 685

87 596

21 Pull out the unit injector. If the unit injector

is stuck, tap carefully with a rubber mallet

on the solenoid valve housing.

22 Remove the cylinder head. Mark the

cylinder heads if more than one is being

removed at the same time.

Cylinder head