Renault Scenic 3 Chassis. Manual - part 22

35B

-

1

TYRE PRESSURE MONITOR

Description

35B

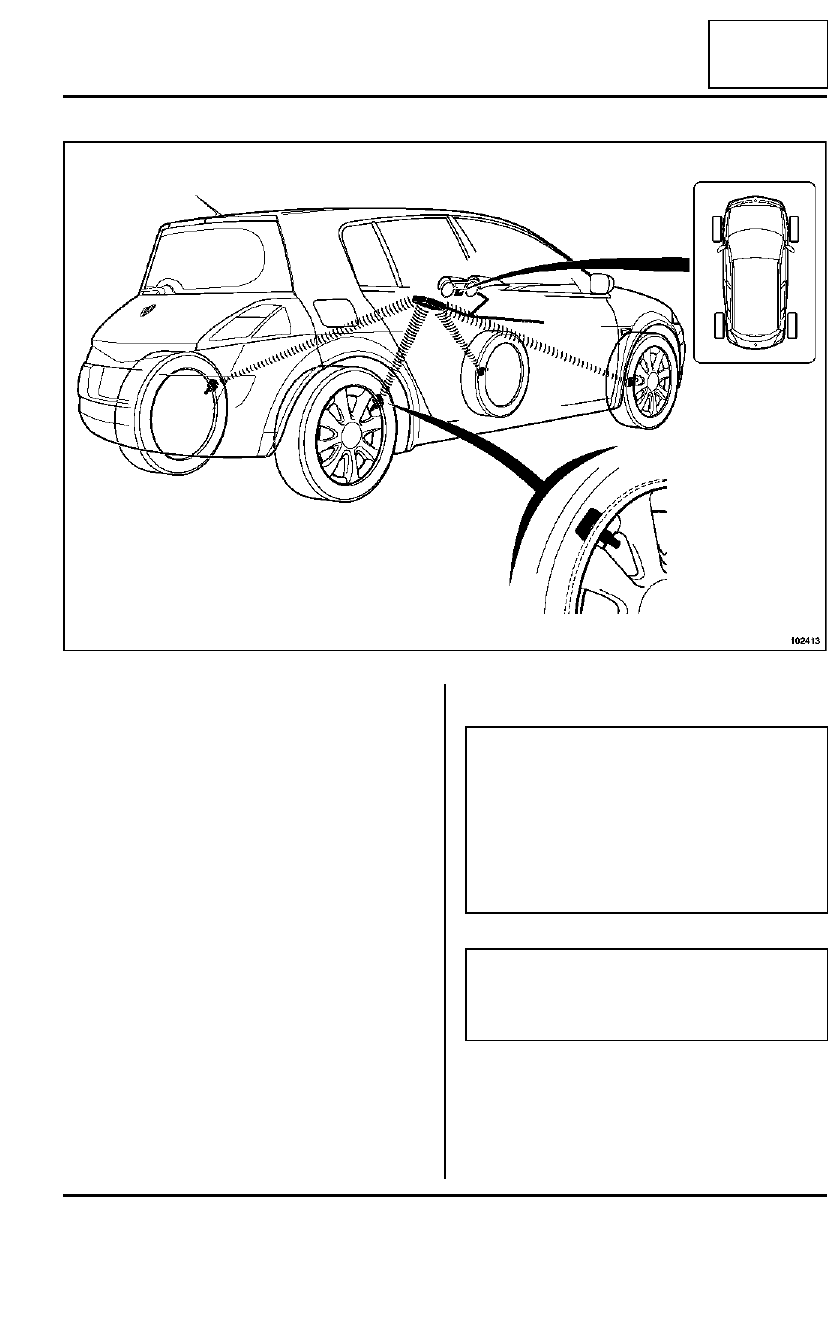

This system continuously monitors the pressure status

of the vehicle's four tyres and any system malfunctions.

The spare wheel is not monitored.

The system warns the driver in the event of:

- overinflation,

- under-inflation,

- puncture,

- tyre inflation pressure inappropriate for the vehicle

speed,

- slow puncture between left-hand and right-hand tyres,

- left - right imbalance when starting,

- sensor failure.

The system corrects the pressures measured against

the coldest tyre. The corrected pressure is used to de-

tect leaks and left - right imbalance.

The system comprises:

- four pressure sensors built into the valves (one per

wheel); they transmit a radio frequency signal,

- the UCH, which collects, decodes and processes si-

gnals from the sensors, then determines which mes-

sage to display,

- a display built into the instrument panel.

102413

Note:

Each sensor is identified by a coloured marking

round the valve:

- green = front left,

- yellow = front right,

- red = rear left,

- black = rear right.

WARNING

Be sure to follow the colour coding, so that the sys-

tem displays the signals correctly. A unique code

enables the UCH to recognise each sensor.