Opel Karl (2019 year). Manual - part 10

150

Vehicle care

12. Proceed to the left side rear

wheel, and repeat the procedure

in Step 9. The horn sounds twice

to indicate that the sensor

identification code has been

matched to the left side rear

wheel, and the tyre pressure

sensor matching process is no

longer active.

13. Turn off the ignition.

14. Set all four tyres to the

recommended air pressure level

as indicated on the tyre

information label.

15. Ensure the tyre loading status is

set according to the selected

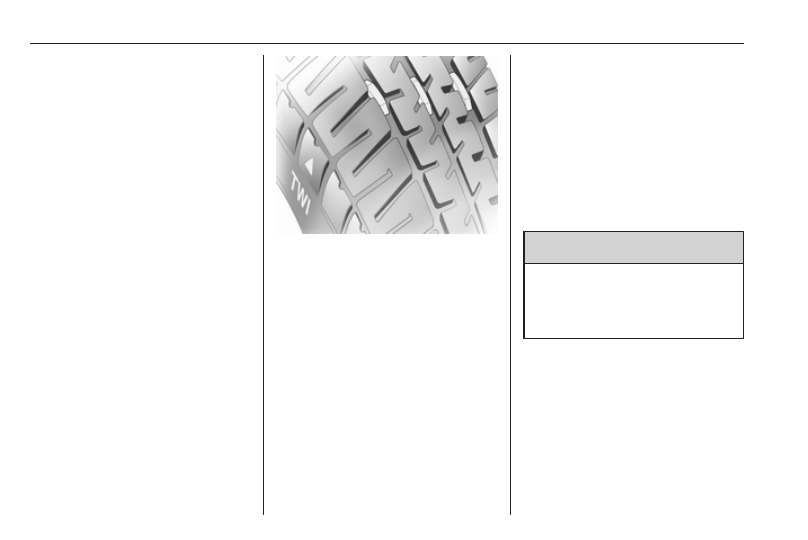

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than

2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be

necessary to reprogramme the

nominal tyre pressure and make

other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.