Opel Combo (2018 year). Manual - part 10

150

Vehicle care

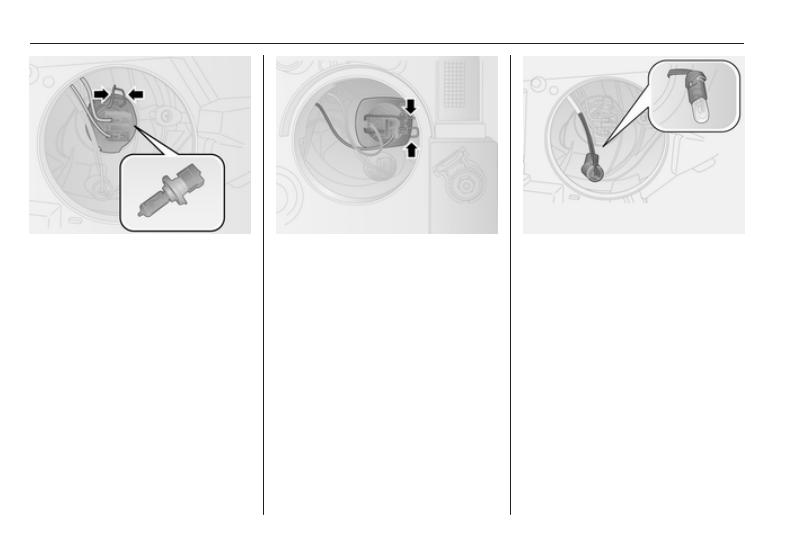

4. Insert new bulb in reflector so that

the locating tab of the bulb aligns

with the reflector recess.

5. Attach connector to bulb.

6. Engage wire clip.

7. Install protective cover.

High beam

1. Remove protective cover.

2. Detach connector from bulb.

3. Disengage wire clip and remove

bulb from reflector.

4. Insert new bulb in reflector so that

the bulb aligns with the reflector

recess.

5. Engage wire clip and attach

connector onto bulb.

6. Install protective cover.

Sidelight

1. Remove protective cover.

Withdraw bulb holder from

reflector by turning anticlockwise.

2. Remove bulb from socket, insert

new bulb.

3. Insert bulb holder in reflector.

4. Rotate clockwise to engage.

5. Install protective cover.

Daytime running light

1. Remove protective cover.