Nissan Altima L32. Manual - part 885

LAN

MAIN LINE BETWEEN DLC AND ABS CIRCUIT

LAN-69

< COMPONENT DIAGNOSIS >

[CAN SYSTEM (TYPE 3)]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

COMPONENT DIAGNOSIS

MAIN LINE BETWEEN DLC AND ABS CIRCUIT

Diagnosis Procedure

INFOID:0000000004203901

INSPECTION PROCEDURE

1.

CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side).

-

Harness connector M1

-

Harness connector E30

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair the terminal and connector.

2.

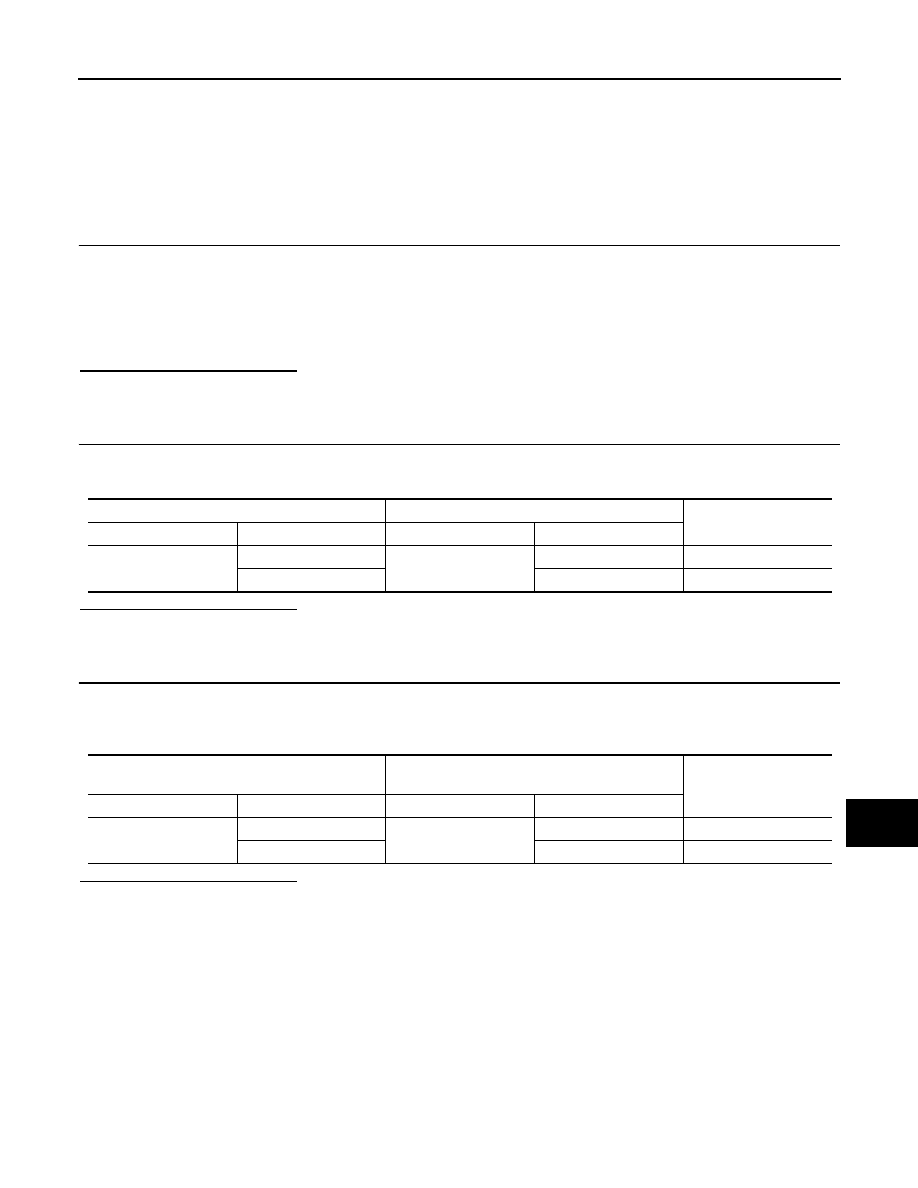

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the harness connectors M1 and E30.

2. Check the continuity between the data link connector and the harness connector.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair the main line between the data link connector and the harness connector M1.

3.

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the connector of ABS actuator and electric unit (control unit).

2. Check the continuity between the harness connector and the ABS actuator and electric unit (control unit)

harness connector.

Is the inspection result normal?

YES (Present error)>>Check CAN system type decision again.

YES (Past error)>>Error was detected in the main line between the data link connector and the ABS actuator

and electric unit (control unit).

NO

>> Repair the main line between the harness connector E30 and the ABS actuator and electric unit

(control unit).

Data link connector

Harness connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

M22

6

M1

15G

Existed

14

8G

Existed

Harness connector

ABS actuator and electric unit (control unit)

harness connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

E30

15G

E26

26

Existed

8G

15

Existed