Nissan Altima L32. Manual - part 806

HA-44

< ON-VEHICLE REPAIR >

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

Removal and Installation for Refrigerant Pressure Sensor

INFOID:0000000004205510

REMOVAL

1. Discharge the refrigerant. Refer to

HA-32, "HFC-134a (R-134a) Service Procedure"

.

2. Remove the front grille. Refer to

EXT-17, "Removal and Installation"

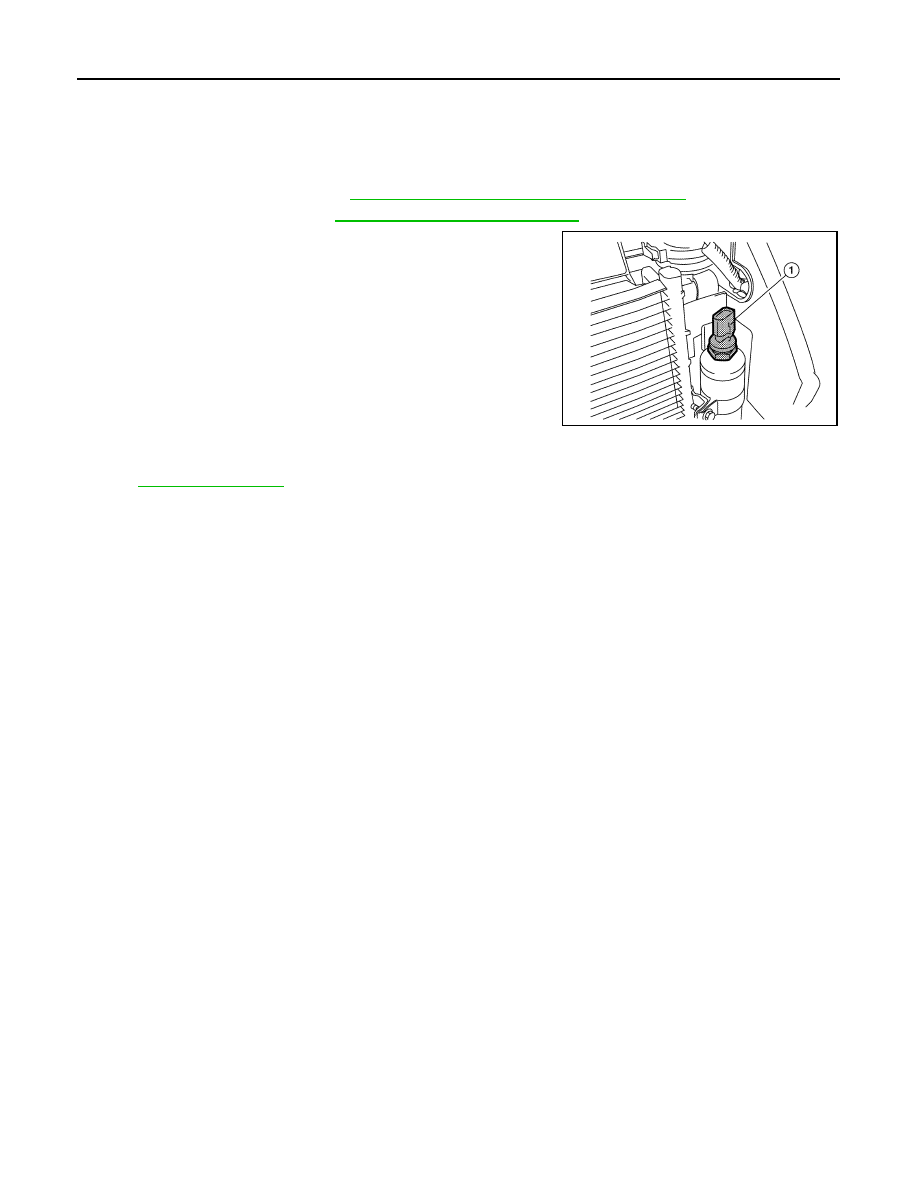

3. Disconnect the refrigerant pressure sensor connector and

remove the refrigerant pressure sensor (1) from the liquid tank

on the condenser.

CAUTION:

Do not damage the condenser fins.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace the O-ring of the refrigerant pressure sensor with a new one, then apply compressor oil to it

when installing it.

ALIIA0004ZZ