Nissan Altima L32. Manual - part 648

EM-128

< ON-VEHICLE MAINTENANCE >

[VQ35DE]

COMPRESSION PRESSURE

COMPRESSION PRESSURE

On-Vehicle Service

INFOID:0000000004202157

CHECKING COMPRESSION PRESSURE

1. Run the engine until it reaches normal operating temperature.

2. Turn the ignition switch to OFF.

3. Release fuel pressure and leave the fuel pump electrically disconnected.

4. Remove all six spark plugs.

EM-119, "Removal and Installation"

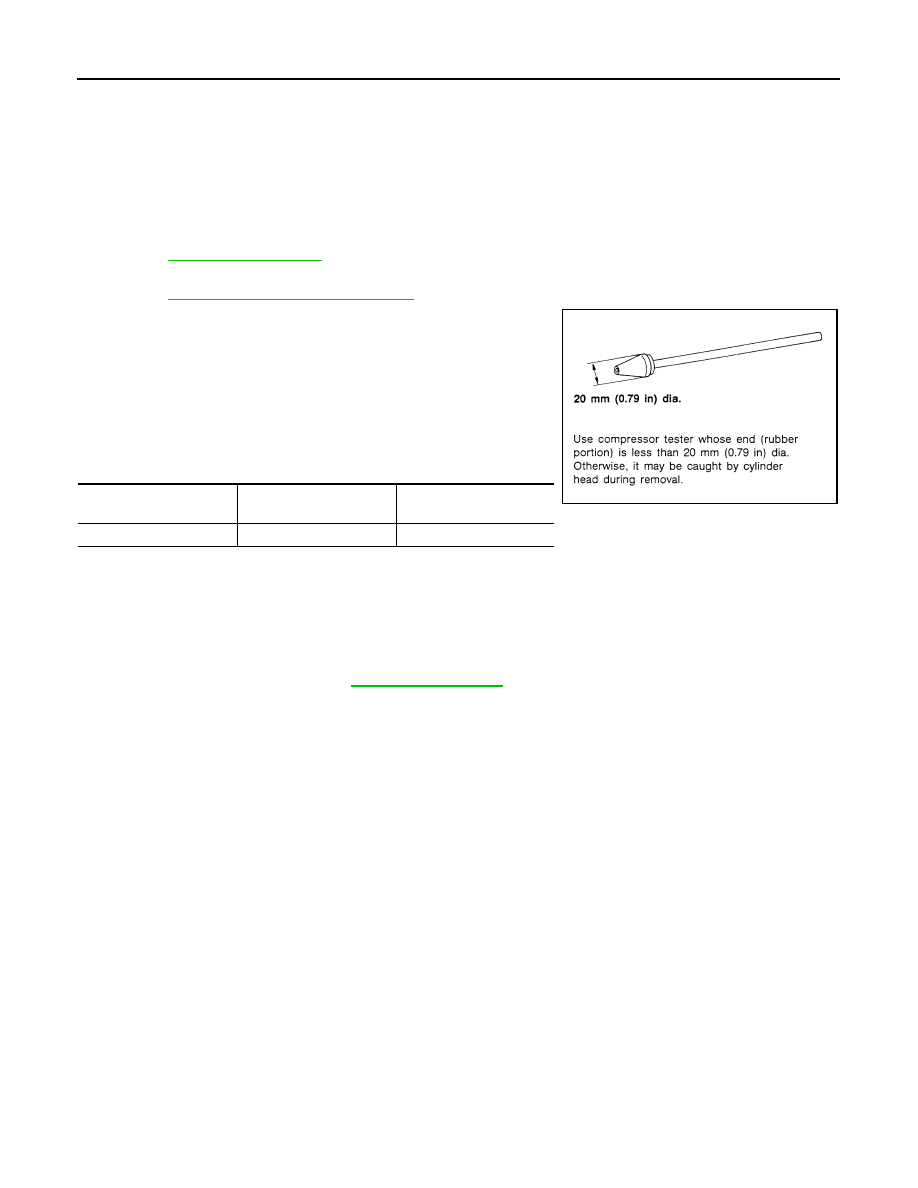

5. Attach a compression tester to No. 1 cylinder.

6. Depress accelerator pedal fully to keep the electric throttle con-

trol actuator butterfly-valve wide open to maximize air intake

flow.

7. Crank the engine and record the highest gauge indication.

8. Repeat the measurement on each cylinder (steps 5 - 7).

• Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (kg/cm

2

, psi)/rpm

9. If compression in one or more cylinders is low:

a. Pour a small amount of engine oil into cylinders through the spark plug holes.

b. Retest compression (steps 5 - 8).

• If adding oil helps raise compression pressure, then the piston rings may be worn or damaged. If so,

replace piston rings after checking piston.

• If the pressure stays low, a valve may be sticking or is seating improperly. Inspect and repair the

valve and/or valve seat. Refer to

. If the valve and/or valve seat is damaged

excessively, replace as necessary.

• If compression stays low in two or more cylinders that are next to each other:

- The cylinder head gasket may be leaking.

- Both cylinders may have valve component damage. Inspect and repair as necessary.

Standard

Minimum

Difference limit between

cylinders

1,275 (13.0, 185)/300

981 (10.0, 142)/300

98 (1.0, 14)/300

SEM387C