Nissan Altima L32. Manual - part 634

EM-72

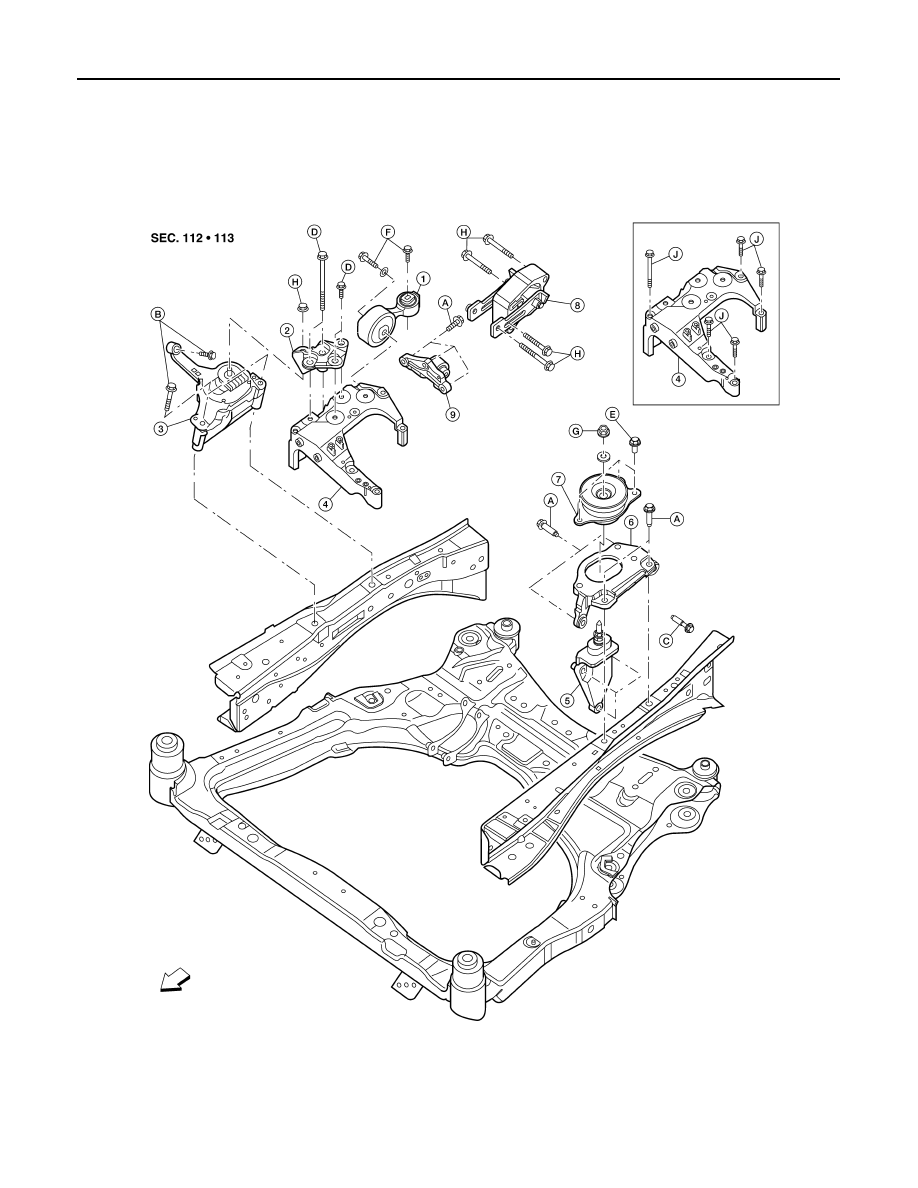

< REMOVAL AND INSTALLATION >

[QR25DE]

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

Removal and Installation

INFOID:0000000004202133

ALBIA0550ZZ

1.

RH engine mount torque rod

2.

RH engine support bracket

3.

RH engine mounting insulator

4.

RH engine mounting bracket

5.

Transmission mounting bracket

6.

LH engine mounting bracket

7.

LH engine mounting insulator

8.

Rear engine mount torque rod

9.

Rear engine mount torque rod bracket

A. 40 N·m (4.1 kg-m, 30 ft-lb)

B. 41 N·m (4.2 kg-m, 30 ft-lb)

C. 45 N·m (4.6 kg-m, 33 ft-lb)

D. 50 N·m (5.1 kg-m, 37 ft-lb)

E. 60 N·m (6.1 kg-m, 44 ft-lb)

F.

85 N·m (8.7 kg-m, 63 ft-lb)