Nissan Altima L32. Manual - part 364

MULTIPORT FUEL INJECTION SYSTEM

EC-577

< FUNCTION DIAGNOSIS >

[QR25DE EXCEPT FOR CALIFORNIA]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

MULTIPORT FUEL INJECTION SYSTEM

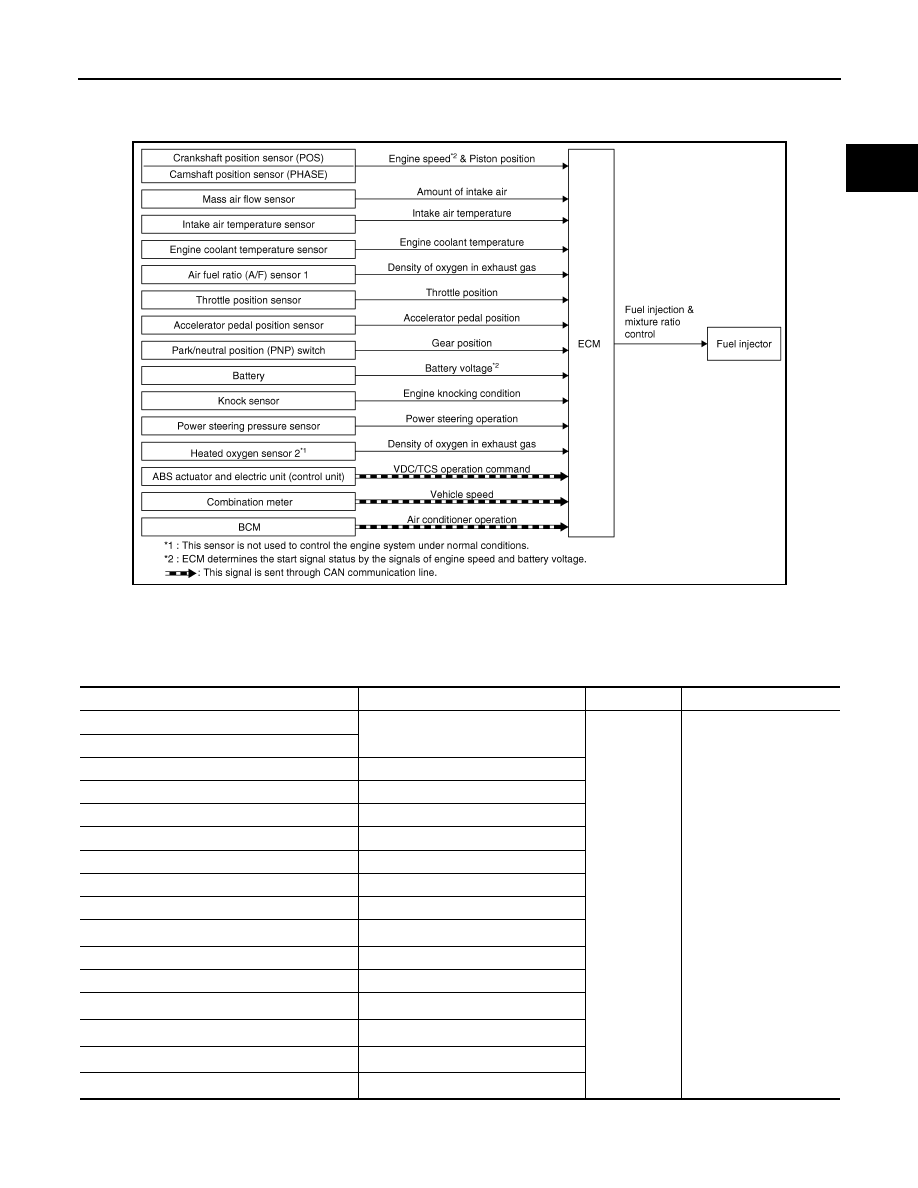

System Diagram

INFOID:0000000004349604

System Description

INFOID:0000000004349605

INPUT/OUTPUT SIGNAL CHART

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM through CAN communication line.

JMBIA0173GB

Sensor

Input Signal to ECM

ECM function

Actuator

Crankshaft position sensor (POS)

Engine speed*

3

Piston position

Fuel injection

& mixture ratio

control

Fuel injector

Camshaft position sensor (PHASE)

Mass air flow sensor

Amount of intake air

Intake air temperature sensor

Intake air temperature

Engine coolant temperature sensor

Engine coolant temperature

Air fuel ratio (A/F) sensor 1

Density of oxygen in exhaust gas

Throttle position sensor

Throttle position

Accelerator pedal position sensor

Accelerator pedal position

Park/neutral position (PNP) switch

Gear position

Battery

Battery voltage*

3

Knock sensor

Engine knocking condition

Power steering pressure sensor

Power steering operation

Heated oxygen sensor 2*

1

Density of oxygen in exhaust gas

ABS actuator and electric unit (control unit)*

2

ABS operation command

BCM

Air conditioner operation*

2

Combination meter

Vehicle speed*

2