Content .. 1579 1580 1581 1582 ..

Nissan Altima L32. Manual - part 1581

ROAD WHEEL TIRE ASSEMBLY

WT-67

< ON-VEHICLE REPAIR >

C

D

F

G

H

I

J

K

L

M

A

B

WT

N

O

P

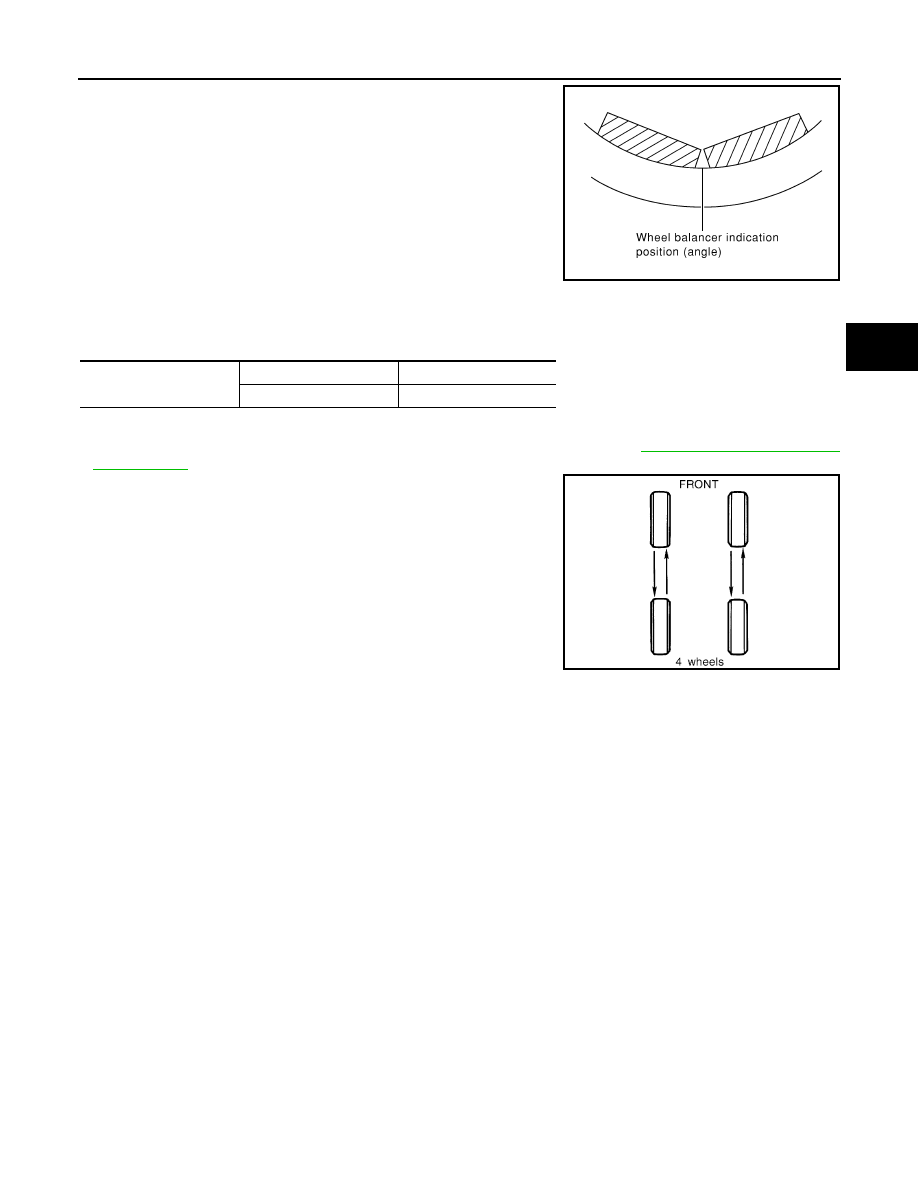

c. If calculated balance weight value exceeds 50 g (1.76 oz.),

install two balance weight sheets in line with each other as

shown.

CAUTION:

Do not install one balance weight sheet on top of another.

5. Start wheel balancer again.

6. Install drive-in balance weight on inner side of road wheel in the

wheel balancer indication position (angle).

CAUTION:

Do not install more than two balance weights.

7. Start wheel balancer. Make sure that inner and outer residual

unbalance values are 5 g (0.18 oz.) each or below.

• If either residual unbalance value exceeds 5 g (0.18 oz.), repeat installation procedures.

Wheel balance (Maximum allowable unbalance):

TIRE ROTATION

• Follow the maintenance schedule for tire rotation service intervals. Refer to

.

• Do not include the T-type spare tire when rotating the tires.

CAUTION:

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the

criteria for preventing strain of disc rotor.

Maximum allowable un-

balance

Dynamic (At rim flange)

5 g (0.18 oz.) (one side)

Static

10 g (0.35 oz.)

SMA056D

Tightening torque of

wheel nut

: 113 N·m (12 kg-m, 83 ft-lb)

SMA829C