Content .. 1515 1516 1517 1518 ..

Nissan Altima L32. Manual - part 1517

TM-412

< PRECAUTION >

[CVT: RE0F10A]

PRECAUTIONS

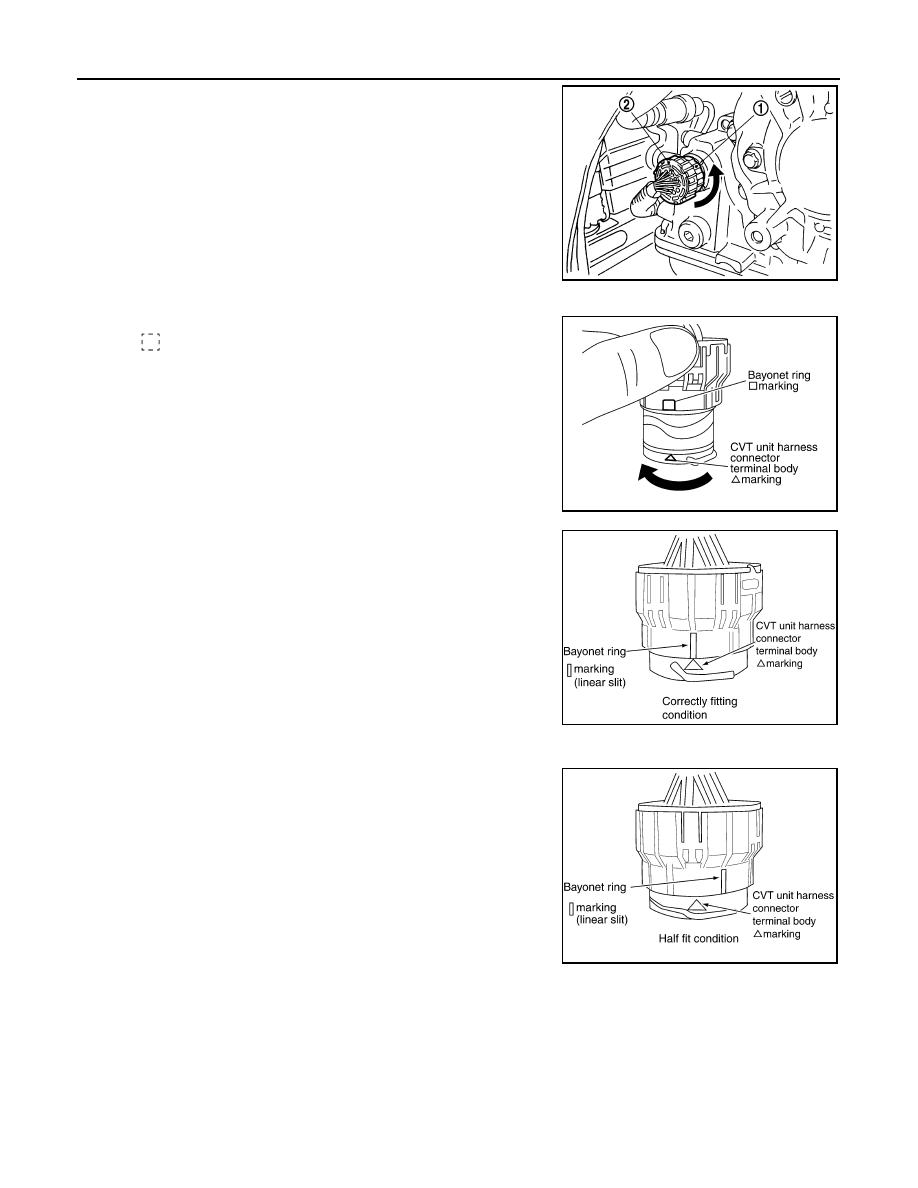

Rotate bayonet ring (1) counterclockwise, pull out CVT unit harness

connector (2) and remove it.

INSTALLATION

1. Align

∆ marking on CVT unit harness connector terminal body

with marking on bayonet ring, insert CVT unit harness con-

nector, and then rotate bayonet ring clockwise.

2. Rotate bayonet ring clockwise until

∆ marking on CVT unit har-

ness connector terminal body is aligned with the slit on bayonet

ring as shown in the figure (correctly fitting condition), install

CVT unit harness connector to CVT unit harness connector ter-

minal body.

CAUTION:

• Securely align

∆ marking on CVT unit harness connector

terminal body with bayonet ring slit. Then, be careful not

to make a half fit condition as shown in the figure.

• Do not mistake the slit of bayonet ring for other dent por-

tion.

Precaution

INFOID:0000000004201987

NOTE:

If any malfunction occurs in the RE0F10A model transaxle, replace the entire transaxle assembly.

SCIA6685J

SCIA2097E

SCIA2098E

SCIA2099E