Nissan Titan. Manual - part 353

COIL SPRING AND SHOCK ABSORBER

FSU-11

< REMOVAL AND INSTALLATION >

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

COIL SPRING AND SHOCK ABSORBER

Removal and Installation

INFOID:0000000009885599

REMOVAL

1. Remove the wheel and tire using power tool. Refer to

.

2. Turn steering knuckle out to gain enough clearance for removal.

3. Remove the shock absorber lower bolt using power tool.

4. Remove the three shock absorber upper nuts using power tool.

5. Remove the coil spring and shock absorber.

INSTALLATION

Installation is in the reverse order of removal.

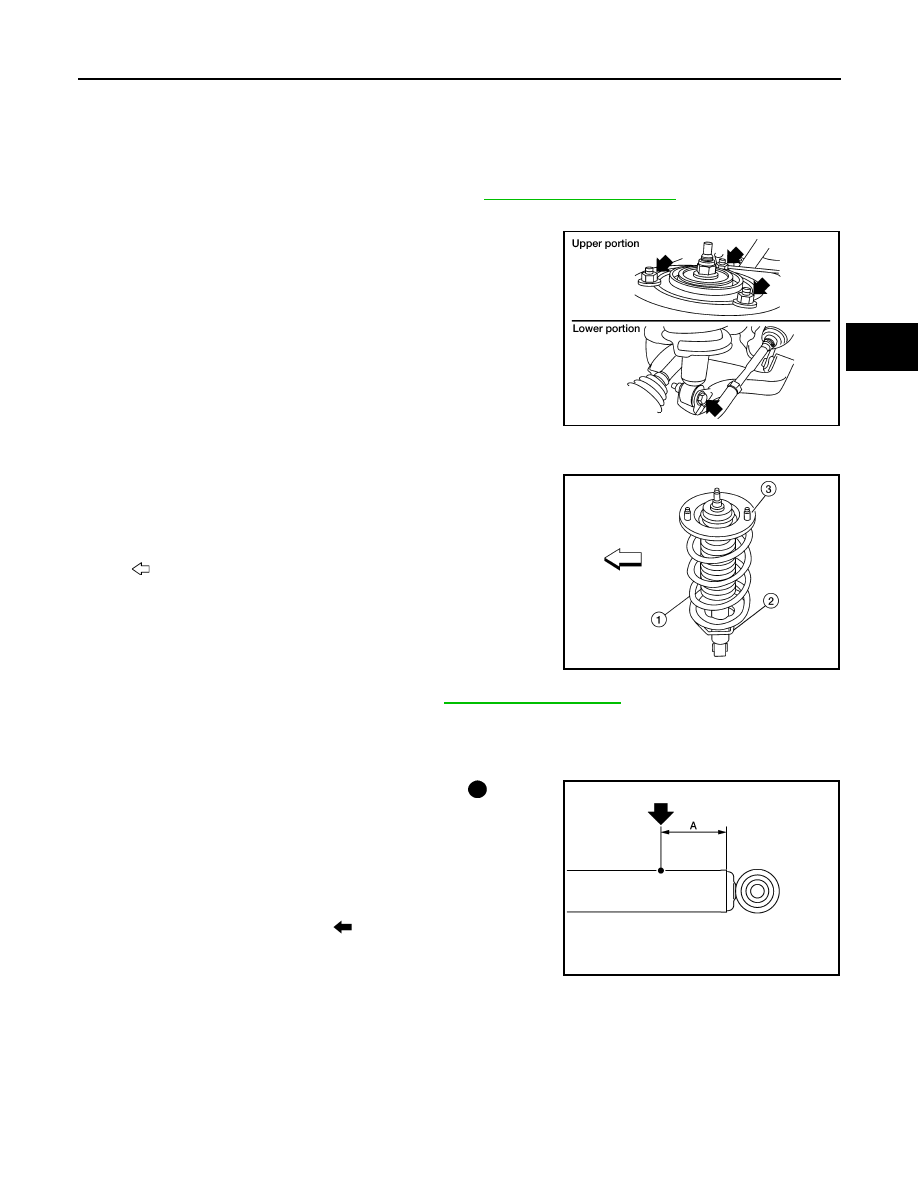

• Position the coil spring and shock absorber (1) in the vehicle with

the studs on the shock absorber mounting insulator (3) in line with

the lower shock mount and the lower seat step (2). The lower seat

step faces the outside of the vehicle.

• Tighten all nuts and bolts to specification. Refer to

.

Disposal

INFOID:0000000009885600

1. Set shock absorber horizontally with the piston rod fully extended.

2. Drill 2 – 3 mm (0.08 – 0.12 in) hole at the position ( ) from top

as shown to release gas gradually.

CAUTION:

• Wear eye protection (safety glasses).

• Wear gloves.

• Be careful with metal chips or oil blown out by the com-

pressed gas.

NOTE:

• Drill vertically in this direction (

).

• Directly to the outer tube avoiding brackets.

• The gas is clear, colorless, odorless, and harmless.

3. Position the drilled hole downward and drain oil by moving the piston rod several times.

CAUTION:

Dispose of drained oil according to the law and local regulations.

LEIA0093E

: Front

WEIA0155E

(A) : 20 – 30 mm (0.79 – 1.18 in)

JPEIA0161ZZ