Nissan Quest E52. Manual - part 501

EC-214

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

P0132, P0152 A/F SENSOR 1

With GST

Follow the procedure “With CONSULT” above.

Is 1st trip DTC detected?

YES

>> Proceed to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000009651072

1.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY

1.

Disconnect A/F sensor 1 harness connector.

2.

Turn ignition switch ON.

3.

Check the voltage between A/F sensor 1 harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> GO TO 2.

2.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect IPDM E/R harness connector.

3.

Check the continuity between A/F sensor 1 harness connector and IPDM E/R harness connector.

Is the inspection result normal?

YES

>> Perform the trouble diagnosis for power supply circuit.

NO

>> Repair or replace error-detected parts.

3.

CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

4.

Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector

and ground.

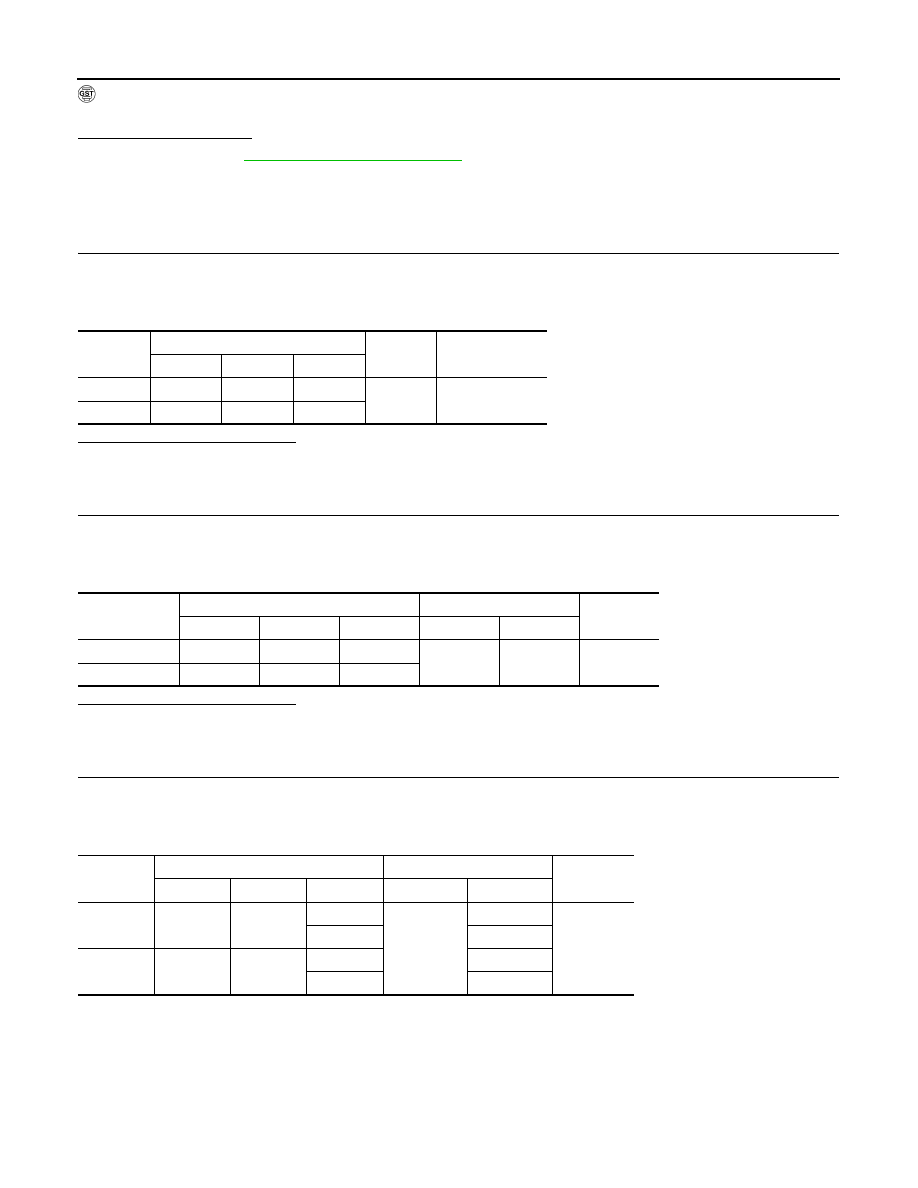

DTC

A/F sensor 1

Ground

Voltage

Bank

Connector

Terminal

P0132

1

F27

4

Ground

Battery voltage

P0152

2

F64

4

DTC

A/F sensor 1

IPDM E/R

Continuity

Bank

Connector

Terminal

Connector

Terminal

P0132

1

F27

4

F12

57

Existed

P0152

2

F64

4

DTC

A/F sensor 1

ECM

Continuity

Bank

Connector

Terminal

Connector

Terminal

P0132

1

F27

1

F8

69

Existed

2

73

P0152

2

F64

1

77

2

81