Content .. 1001 1002 1003 1004 ..

Nissan Quest E52. Manual - part 1003

PWC-124

< REMOVAL AND INSTALLATION >

[DRIVER SIDE WINDOW ANTI-PINCH]

SLIDING DOOR POWER WINDOW SWITCH

SLIDING DOOR POWER WINDOW SWITCH

Removal and Installation

INFOID:0000000009653408

REMOVAL

1.

Remove sliding door finisher. Refer to

.

2.

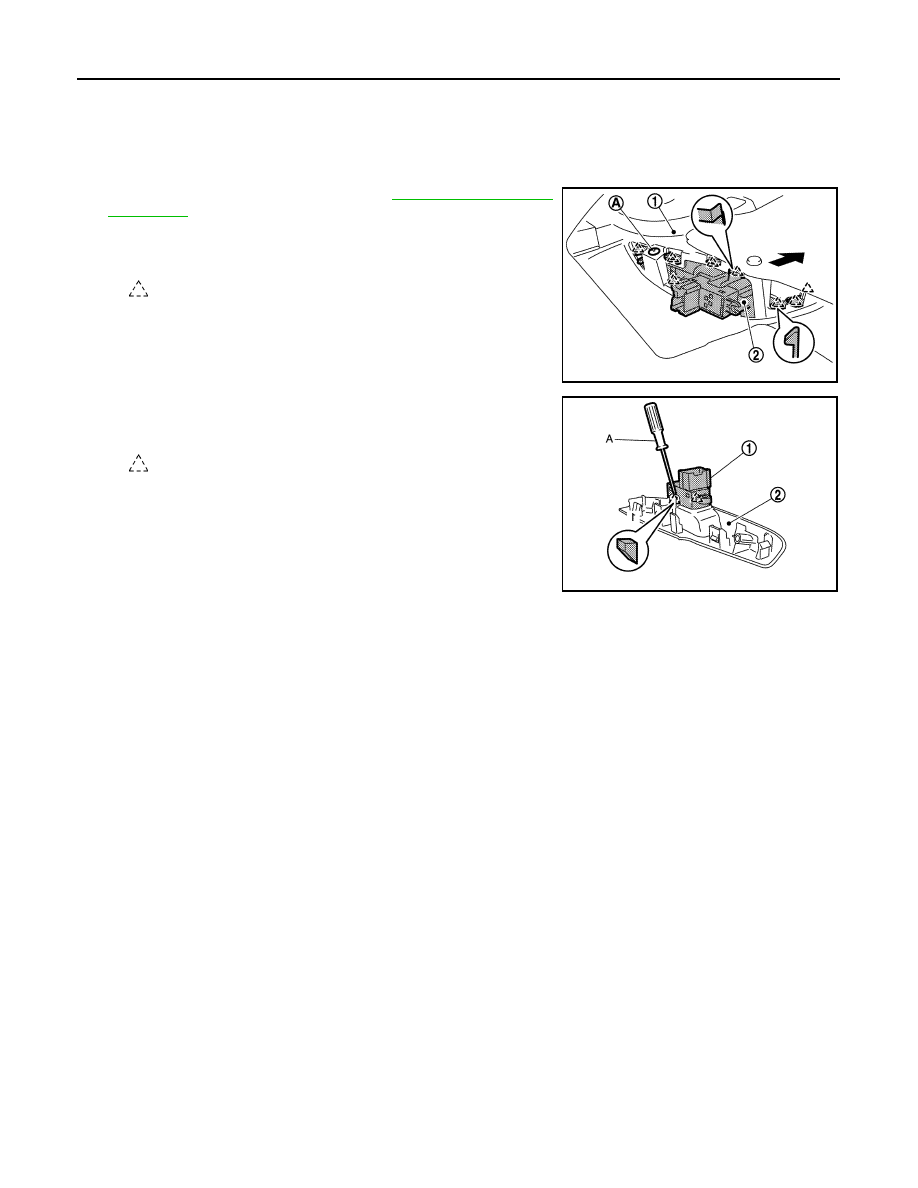

Remove screw (A), disconnect pawls from sliding door finisher

(1), and then remove power window switch finisher (2).

3.

Remove power window switch (1) from power window switch fin-

isher (2) using a remover tool (A).

INSTALLATION

Install in the reverse order of removal.

: Pawl

JMKIA8165ZZ

: Pawl

JMKIA8166ZZ