Nissan Note E12. Manual - part 302

EXL-76

< DTC/CIRCUIT DIAGNOSIS >

HEADLAMP (LO) CIRCUIT

1. Turn ignition switch OFF.

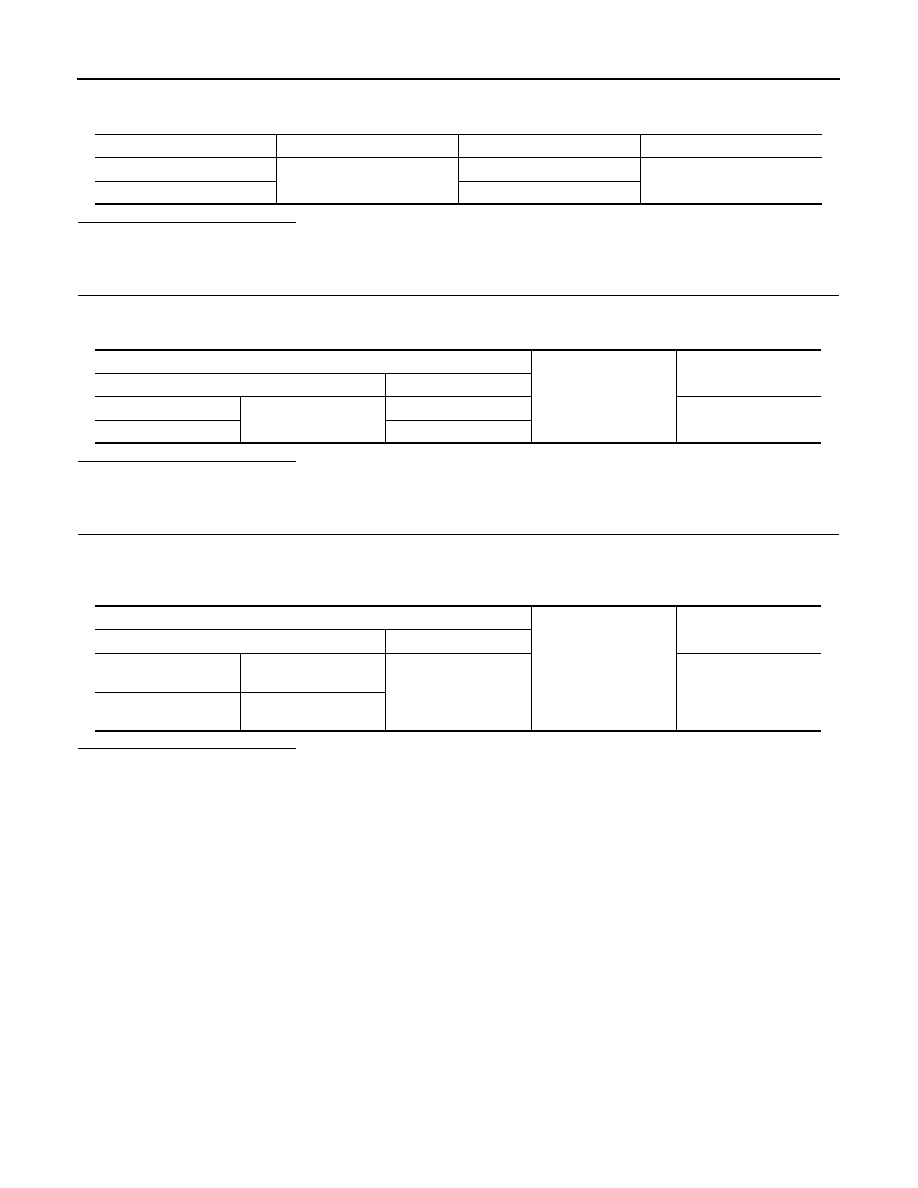

2. Check that the following fuses are not blown.

Is the inspection result normal?

YES

>> Replace IPDM E/R.

NO

>> GO TO 4.

4.

CHECK HEADLAMP (LO) SHORT CIRCUIT

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal?

YES

>> Replace fuse. (Replace IPDM E/R if the fuse is blown again.)

NO

>> Repair or replace harness. And then replace the fuse.

5.

CHECK HEADLAMP (LO) GROUND OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect headlamp low connector.

3. Check continuity between headlamp low harness connector and ground.

Is the inspection result normal?

YES

>> Replace headlamp (LO) bulb. (Bulb socket is abnormal.)

NO

>> Repair or replace harness.

Unit

Lotion

Fuse No.

Capacity

Headlamp LO (RH)

IPDM E/R

#40

15 A

Headlamp LO (LH)

#41

IPDM E/R

Ground

Continuity

Connector

Terminal

RH

E44

16

No

LH

14

Headlamp low

Ground

Continuity

Connector

Terminal

RH

E26 (without DTRL)

E73 (with DTRL)

2

Yes

LH

E25 (without DTRL)

E74 (with DTRL)