Nissan Note E12. Manual - part 215

P0139 HO2S2

EC-199

< DTC/CIRCUIT DIAGNOSIS >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

1. Check the continuity between HO2S2 harness connector and ECM harness connector.

2. Check the continuity between HO2S2 harness connector or ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.

CHECK HEATED OXYGEN SENSOR 2

EC-199, "Component Inspection"

Is the inspection result normal?

YES

>> Refer to

GI-41, "Intermittent Incident"

.

NO

>> Replace heated oxygen sensor 2. Refer to

.

Component Inspection

INFOID:0000000009582430

1.

INSPECTION START

Do you have CONSULT?

Do you have CONSULT?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

CHECK HEATED OXYGEN SENSOR 2

With CONSULT

1. Turn ignition switch ON and select “ENGINE” using CONSULT.

2. Select “DATA MONITOR” mode.

3. Start engine and warm it up to the normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

6. Let engine idle for 1 minute.

7. Select “FUEL INJECTION” in “ACTIVE TEST” mode, and select “HO2S2 (B1)” as the monitor item with

CONSULT.

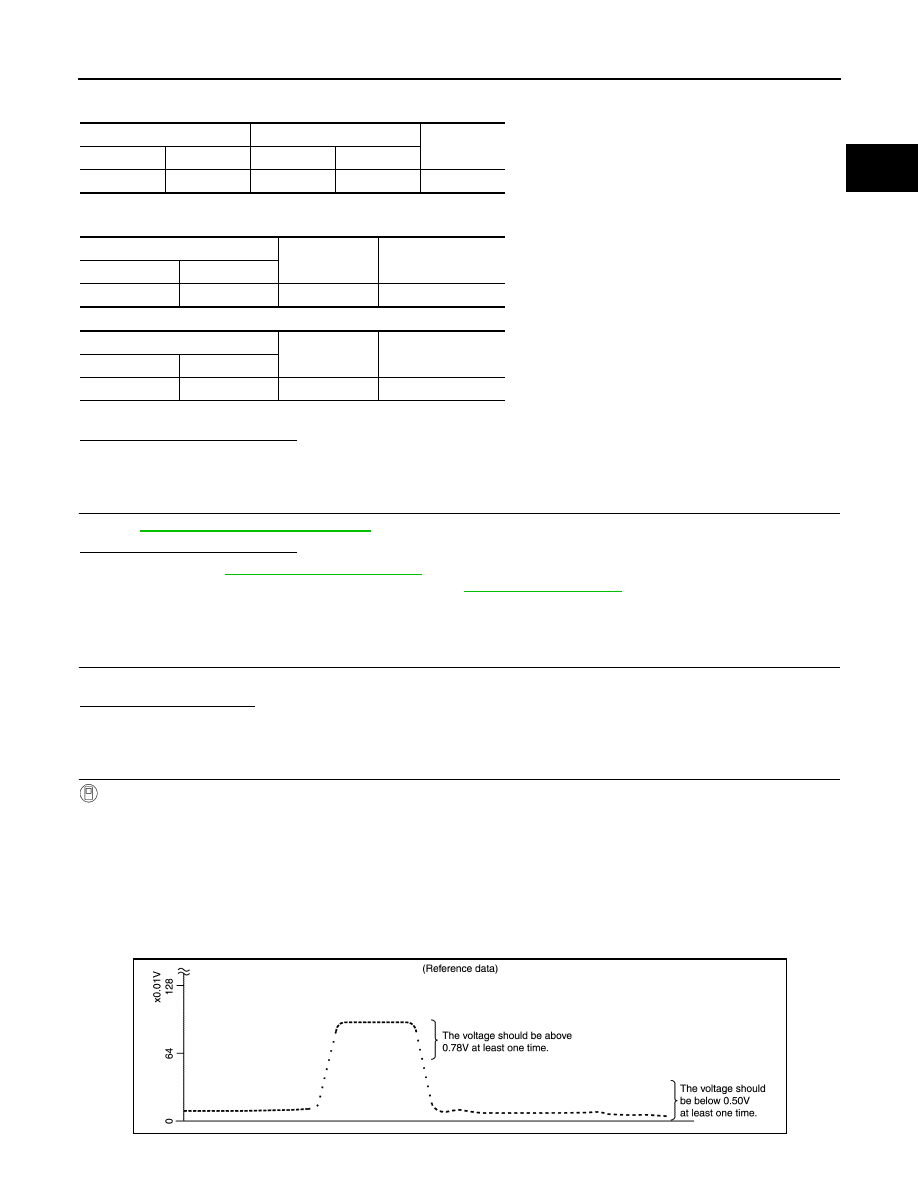

8. Check “HO2S2 (B1)” at idle speed when adjusting “FUEL INJECTION” to

±25%.

HO2S2

ECM

Continuity

Connector

Terminal

Connector

Terminal

E63

4

F11

50

Existed

HO2S2

Ground

Continuity

Connector

Terminal

E63

4

Ground

Not existed

ECM

Ground

Continuity

Connector

Terminal

F11

50

Ground

Not existed

JSBIA1202GB