Nissan Rogue. Manual - part 200

CHG-18

< DTC/CIRCUIT DIAGNOSIS >

B TERMINAL CIRCUIT

B TERMINAL CIRCUIT

Description

INFOID:0000000011278228

“B” terminal circuit supplies power to charge the battery and to operate the vehicles electrical system.

Diagnosis Procedure

INFOID:0000000011278229

Regarding Wiring Diagram information. Refer to

.

1.

CHECK “B” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “B” terminal is clean and tight.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair terminal “B” connection. Confirm repair by performing complete Charging system test

using the EXP-800 NI or GR8-1200 NI (if available). Refer to applicable Instruction Manual for

proper testing procedures.

2.

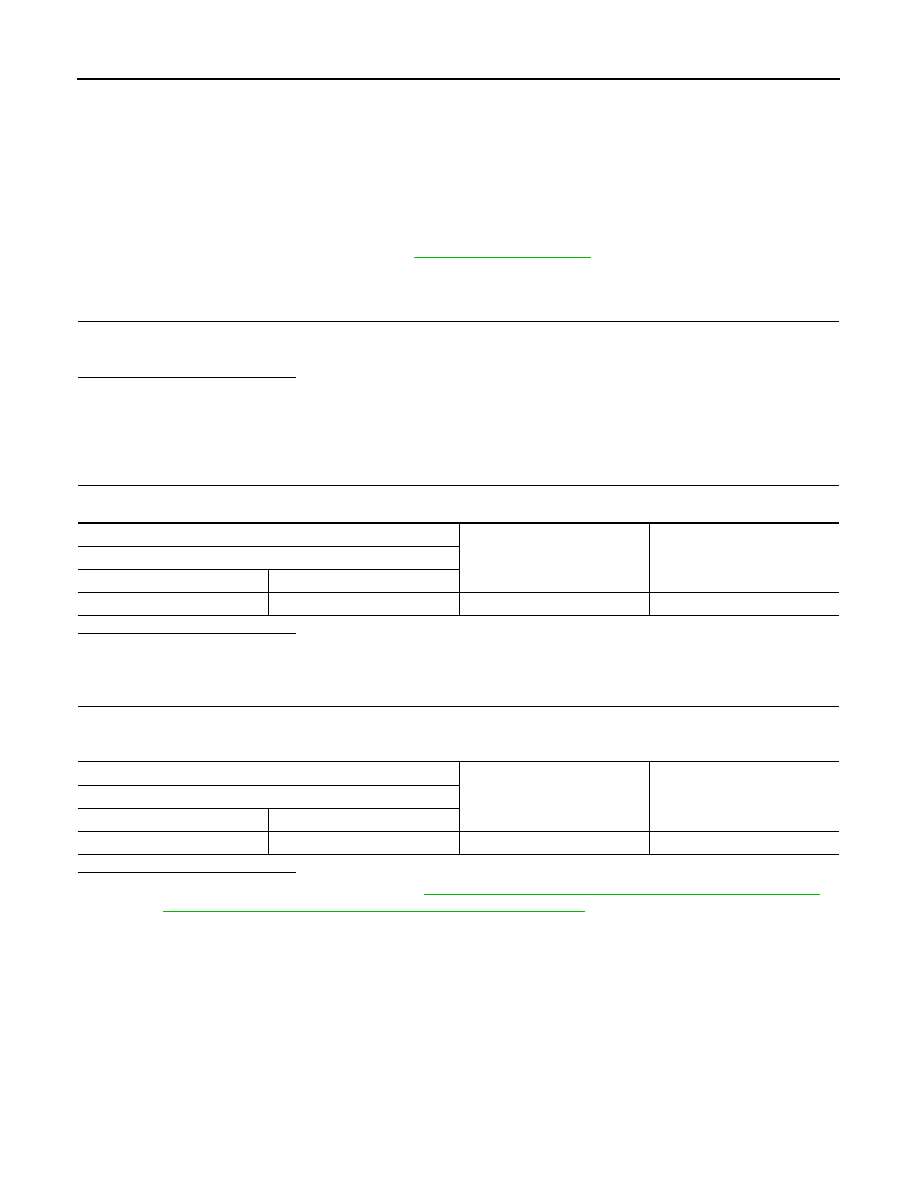

CHECK “B” TERMINAL CIRCUIT

Check voltage between generator “B” terminal and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Check harness for open between generator and fusible link.

3.

CHECK “B” TERMINAL CONNECTION (VOLTAGE DROP TEST)

1. Start engine, then engine running at idle and warm.

2. Check voltage between battery positive terminal and generator connector “B” terminal.

Is the inspection result normal?

YES

>> “B” terminal circuit is normal. Refer to

CHG-11, "Work Flow (With EXP-800 NI or GR8-1200 NI)"

CHG-14, "Work Flow (Without EXP-800 NI or GR8-1200 NI)"

.

NO

>> Check harness between battery and generator for continuity.

(+)

(-)

Voltage

(Approx.)

Generator

Connector

Terminal

F29

1

Ground

Battery voltage

(+)

(-)

Voltage

(Approx.)

Generator

Connector

Terminal

F29

1

Battery positive terminal

Less than 0.2V