Nissan Maxima. Manual - part 236

BR-12

< BASIC INSPECTION >

BRAKE TUBE AND HOSE

BRAKE TUBE AND HOSE

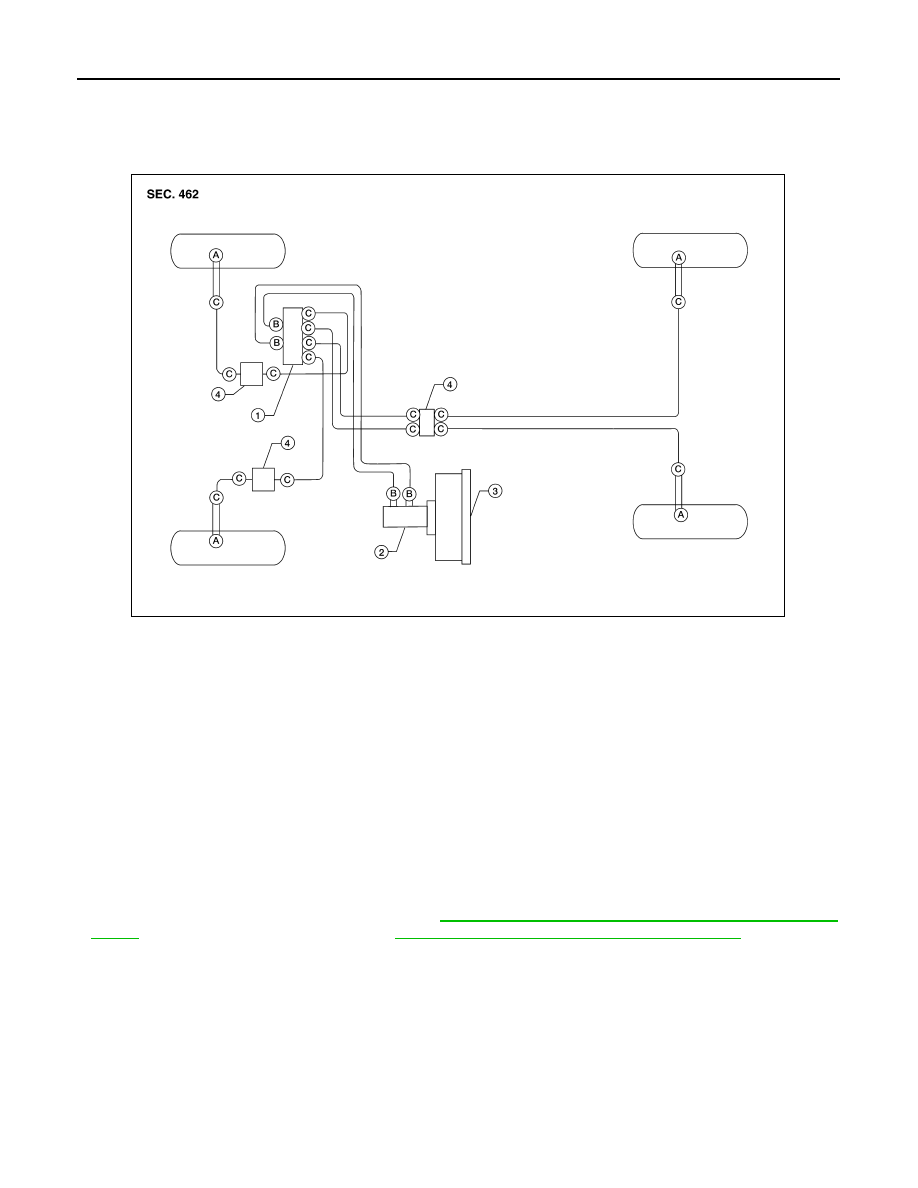

Hydraulic Circuit

INFOID:0000000009466582

CAUTION:

• All hoses and piping (tubes) must be free from excessive bending, twisting and pulling.

• Make sure there is no interference with other parts when turning the steering wheel both clockwise

and counterclockwise.

• The brake piping is an important safety part. If a brake fluid leak is detected, always disassemble the

parts. Replace applicable part with a new one, if necessary.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• Do not bend or twist brake hose sharply, or strongly pull it.

• When removing components, cover connections so that no dirt, dust, or other foreign matter gets in.

• Refill with new specified brake fluid. Refer to

MA-15, "FOR USA AND CANADA : Fluids and Lubri-

(for United States and Canada) or

MA-16, "FOR MEXICO : Fluids and Lubricants"

• Do not reuse drained brake fluid.

FRONT BRAKE

FRONT BRAKE : Inspection

INFOID:0000000009466583

INSPECTION AFTER REMOVAL

CAUTION:

Brake tubes and hoses are important safety parts. Always disassemble the parts and retighten their fit-

tings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged part is

detected.

1.

Actuator

2.

Master cylinder

3.

Brake booster

4.

Connector

A.

Union bolt

18.2 N·m (1.9 kg-m, 13 ft-lb)

B.

Flare nut M12

22.1 N·m (2.3 kg-m, 16 ft-lb)

C.

Flare nut M10

16.2 N·m (1.7 kg-m, 12 ft-lb)

AWFIA0432ZZ