Nissan Altima HL32 Hybrid. Manual - part 305

EC-204

< COMPONENT DIAGNOSIS >

[QR25DE]

P0138 HO2S2

GI-42, "Intermittent Incident"

>> INSPECTION END

9.

CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E9. Refer to Ground Inspection in

.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> Repair or replace ground connection.

10.

CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

1. Clear the mixture ratio self-learning value. Refer to

EC-18, "MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement"

.

2. Activate “INSPECTION MODE 1” (

) to start for at least 10 minutes.

Is the 1st trip DTC P0172 detected? Is it difficult to start engine?

YES

>> Perform trouble diagnosis for DTC P0172. Refer to

.

NO

>> GO TO 11.

11.

CHECK HO2S2 GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect heated oxygen sensor 2 harness connector.

3. Disconnect ECM harness connector.

4. Check the continuity between HO2S2 harness connector and ECM harness connector.

5. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 12.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

12.

CHECK HO2S2 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between HO2S2 harness connector and ECM harness connector.

2. Check the continuity between HO2S2 harness connector or ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal?

YES

>> GO TO 13.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

13.

CHECK HEATED OXYGEN SENSOR 2

EC-205, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 15.

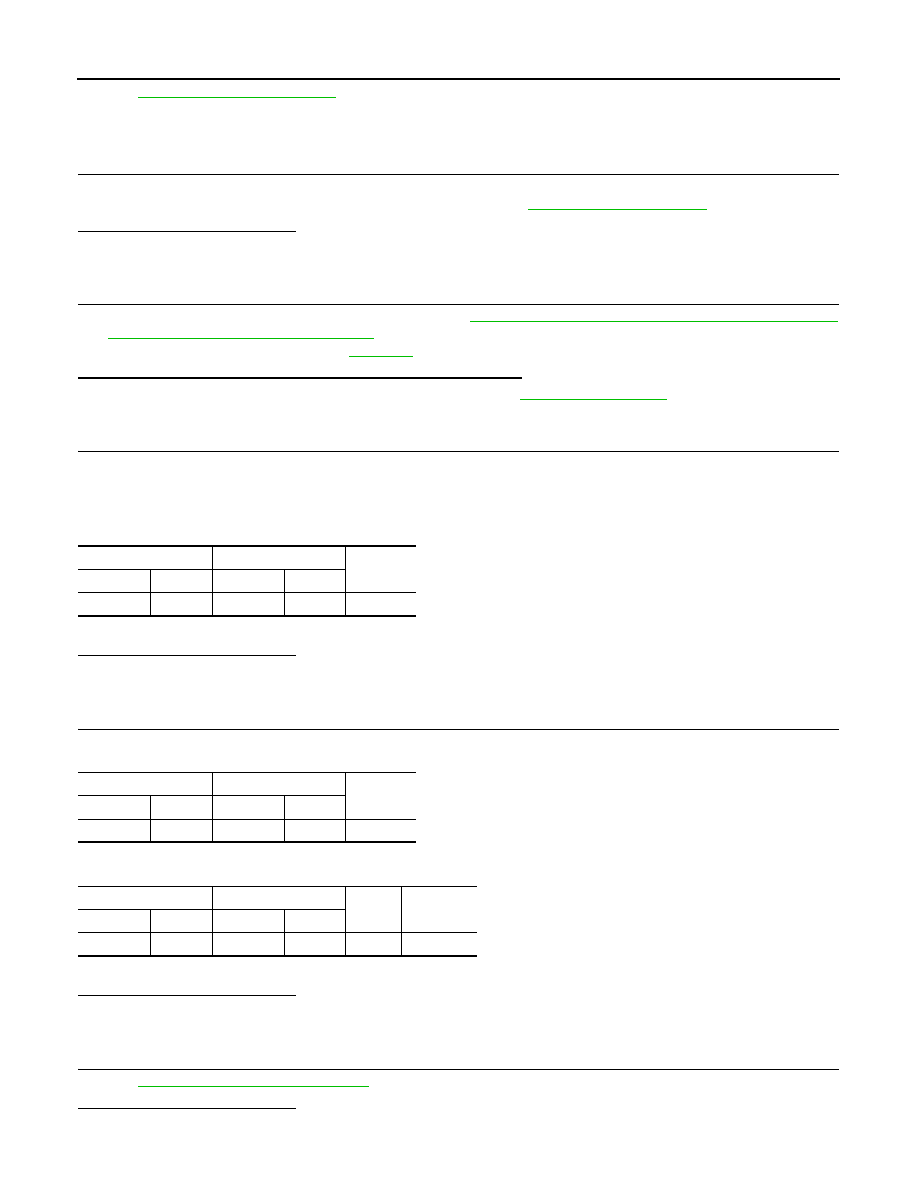

HO2S2

ECM

Continuity

Connector Terminal Connector Terminal

F42

1

F13

35

Existed

HO2S2

ECM

Continuity

Connector Terminal Connector Terminal

F42

4

F13

33

Existed

HO2S2

ECM

Ground

Continuity

Connector Terminal Connector Terminal

F42

4

F13

33

Ground Not existed