Nissan Frontier. Manual - part 758

ENGINE UNIT

EM-221

< UNIT DISASSEMBLY AND ASSEMBLY >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

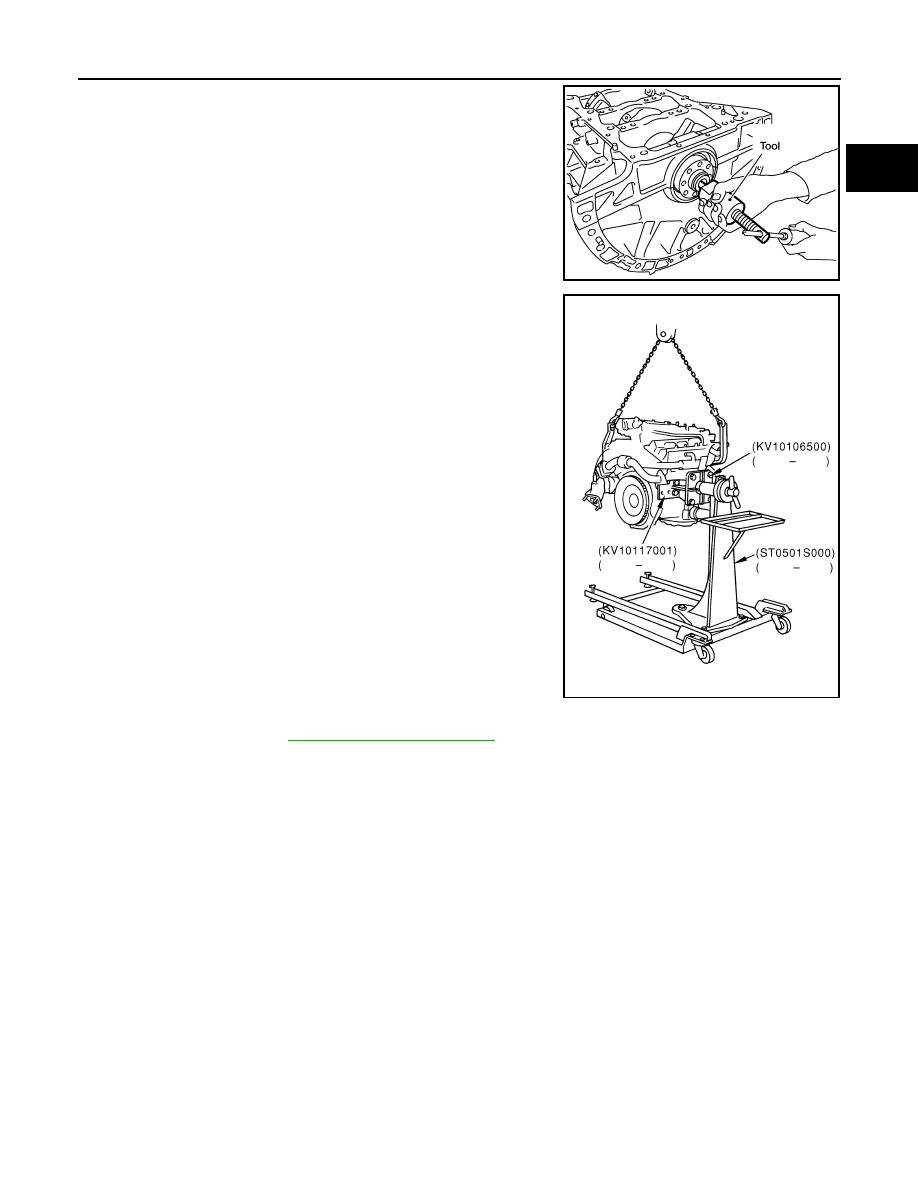

4. Remove pilot converter (A/T models) using Tool as necessary.

5. Lift engine, and mount to engine stand.

CAUTION:

• Use an engine stand that has a load capacity [approxi-

mately 240kg (529 lb) or more] large enough for support-

ing the engine weight.

• Before removing the hanging chains, make sure the

engine stand is stable and there is no risk of overturning.

•

6. Drain engine oil. Refer to

Tool number

: ST16610001 (J-23907)

WBIA0583E

PBIC0805E