Content .. 1272 1273 1274 1275 ..

Nissan Frontier. Manual - part 1274

TRANSMISSION ASSEMBLY

TM-307

< UNIT REMOVAL AND INSTALLATION >

[5AT: RE5R05A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

11. Disconnect the A/T fluid cooler tubes from the A/T assembly.

CAUTION:

Do not reuse copper sealing washers.

12. Remove the dust cover from the converter housing.

13. Turn the crankshaft to access and remove the four bolts for the

drive plate and torque converter.

CAUTION:

When turning the crankshaft, turn it clockwise as viewed

from the front of the engine.

14. Support the A/T assembly using a transmission jack.

CAUTION:

When setting the transmission jack, be careful not to allow

it to collide against the drain plug.

15. Remove the nuts securing the insulator to the crossmember.

16. Remove the crossmember using power tool.

WARNING:

Support the transmission using suitable jack.

17. Tilt the transmission slightly to gain clearance between the body and the transmission, then disconnect

the air breather hose.

18. Disconnect the A/T assembly harness connector.

19. Remove the harness from the retainers.

20. Remove the A/T fluid indicator pipe.

21. Remove the A/T assembly to engine bolts using power tool.

22. Remove A/T assembly from the vehicle using Tool.

CAUTION:

• Secure the torque converter to prevent it from dropping.

• Secure the A/T assembly to a transmission jack.

NOTE:

The actual special service Tool may differ from Tool shown.

INSPECTION

Installation and Inspection of Torque Converter

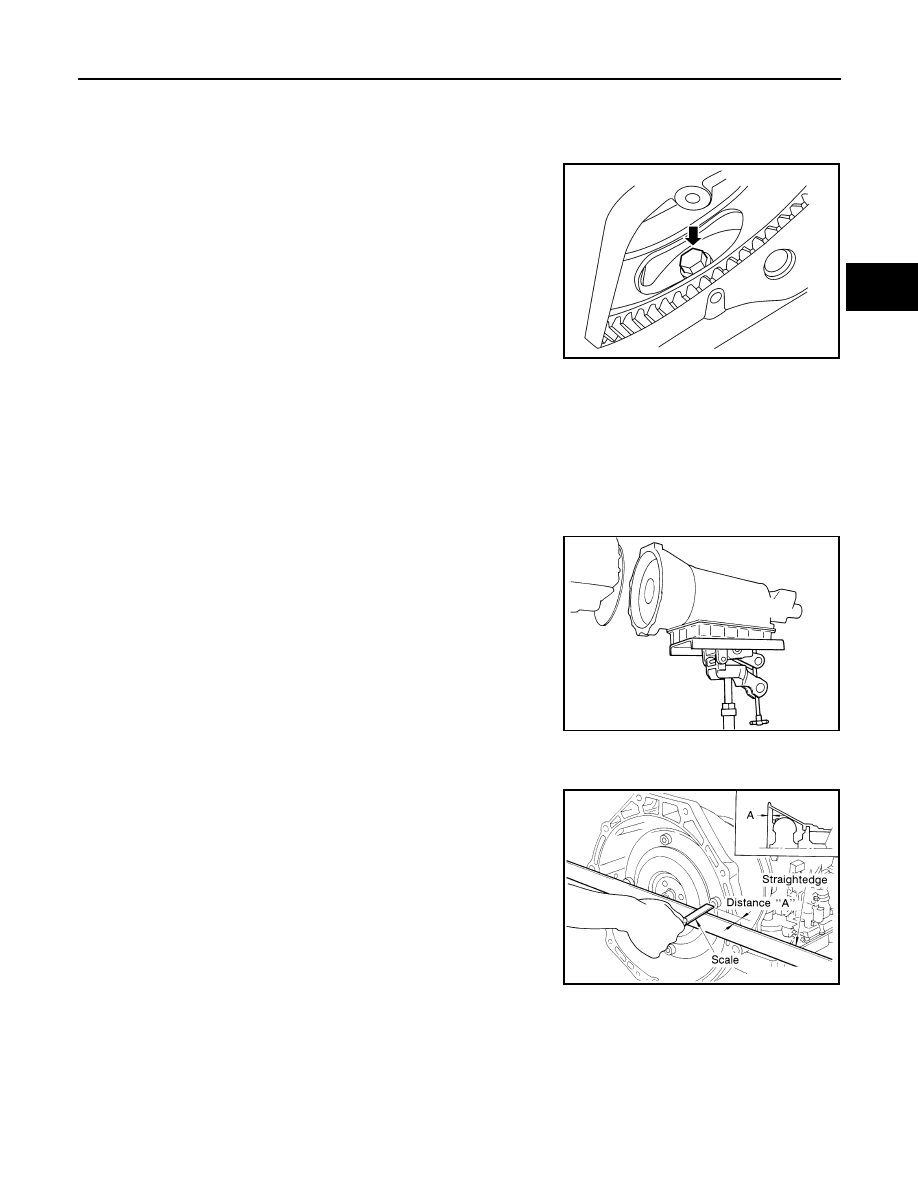

• After inserting a torque converter to a transmission, be sure to

check dimension (A) to ensure it is within the reference value limit.

INSTALLATION

Installation of the remaining components is in the reverse order of the removal, while paying attention to the

following.

Tool number

:

—

(J-47002)

LCIA0335E

SCIA0499E

Dimension (A)

: 25.0 mm (0.98 in) or more

SAT017B