Content .. 1005 1006 1007 1008 ..

Nissan Frontier. Manual - part 1007

CHASSIS AND BODY MAINTENANCE

MA-55

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

STEERING GEAR AND LINKAGE : Checking Steering Gear and Linkage

INFOID:0000000009478681

STEERING GEAR

• Check the steering gear housing for looseness, damage and oil

leakage as shown.

• Check the steering column connections for looseness.

STEERING LINKAGE

• Check the ball joint, dust cover and other component parts for looseness, wear, damage and grease leak-

age.

POWER STEERING FLUID AND LINES

POWER STEERING FLUID AND LINES : Checking Power Steering Fluid and Line

INFOID:0000000009478682

CHECKING FLUID LEVEL

Check fluid level, referring to the scale on the reservoir tank.

Use HOT range for fluid temperatures of 50

°– 80°C (122°– 176°F).

Use COLD range for fluid temperatures of 0

°– 30°C (32°– 86°F).

CAUTION:

• Do not overfill.

• Do not reuse any power steering fluid.

• Recommended fluid is Genuine NISSAN PSF or equivalent.

Refer to

MA-16, "FOR USA AND CANADA : Fluids and Lubri-

(United States and Canada),

(Mexico).

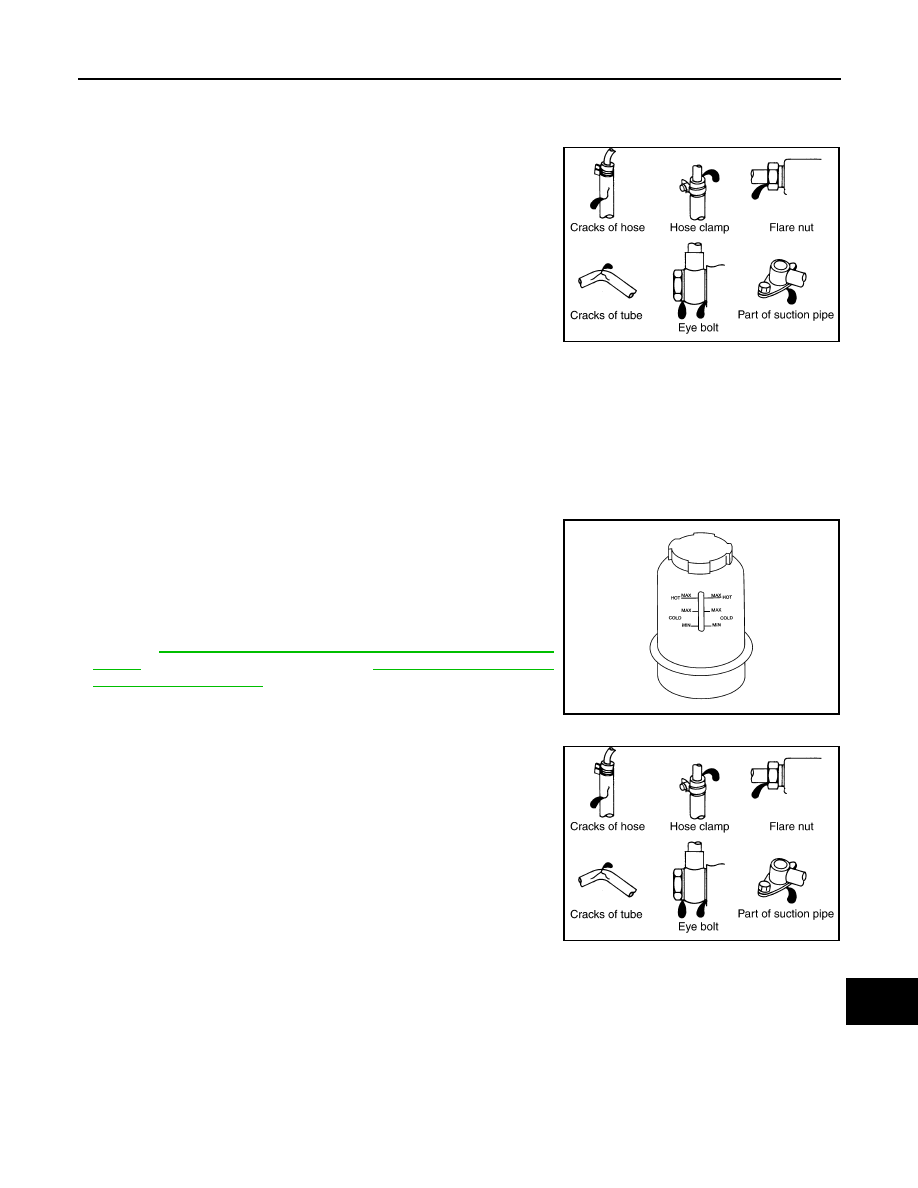

CHECKING LINES

• Check lines for improper attachment, leaks, cracks, damage, loose

connections, chafing and deterioration.

AXLE AND SUSPENSION PARTS

AXLE AND SUSPENSION PARTS : Checking Axle and Suspension Parts

INFOID:0000000009478683

FRONT AND REAR AXLE AND SUSPENSION PARTS

Check front and rear axle and suspension parts for excessive play, cracks, wear or other damage.

SGIA0506E

LGIA0021E

SGIA0506E