Nissan Sentra. Manual - part 713

POWER WINDOW MOTOR

PWC-49

< DTC/CIRCUIT DIAGNOSIS >

C

D

E

F

G

H

I

J

L

M

A

B

PWC

N

O

P

Is the inspection result normal?

YES

>> Check rear power window switch RH. Refer to

PWC-49, "REAR RH : Component Inspection"

NO

>> Repair or replace harness or connectors.

3.

CHECK REAR POWER WINDOW MOTOR RH

Check rear power window motor RH.

PWC-49, "REAR RH : Component Inspection"

.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-39, "Intermittent Incident"

.

NO

>> Replace rear power window motor RH. Refer to

GW-21, "Removal and Installation"

.

REAR RH : Component Inspection

INFOID:0000000009757263

COMPONENT INSPECTION

1.

CHECK REAR POWER WINDOW MOTOR RH

Check motor operation by connecting the battery voltage directly to rear power window motor RH D304.

Is the inspection result normal?

YES

>> Power window motor is OK.

NO

>> Replace rear power window motor RH. Refer to

GW-21, "Removal and Installation"

.

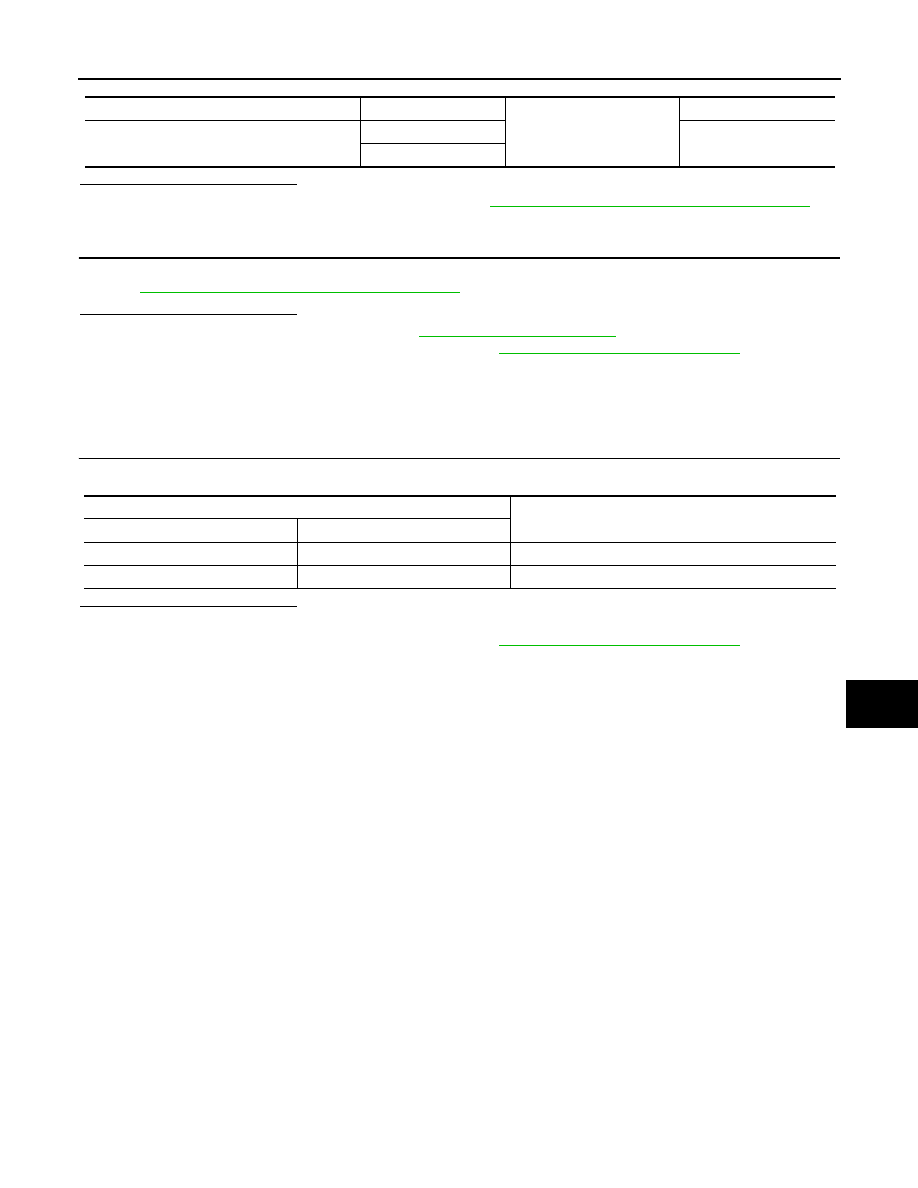

Rear power window switch RH connector

Terminal

Ground

Continuity

D303

5

No

8

Terminal

Motor condition

(+)

(–)

3

1

DOWN

1

3

UP