Nissan Leaf. Manual - part 744

HA-98

< REMOVAL AND INSTALLATION >

[WITHOUT HEAT PUMP SYSTEM]

ELECTRIC COMPRESSOR

WARNING:

To prevent electric shock hazards, be sure to wear protective gear.

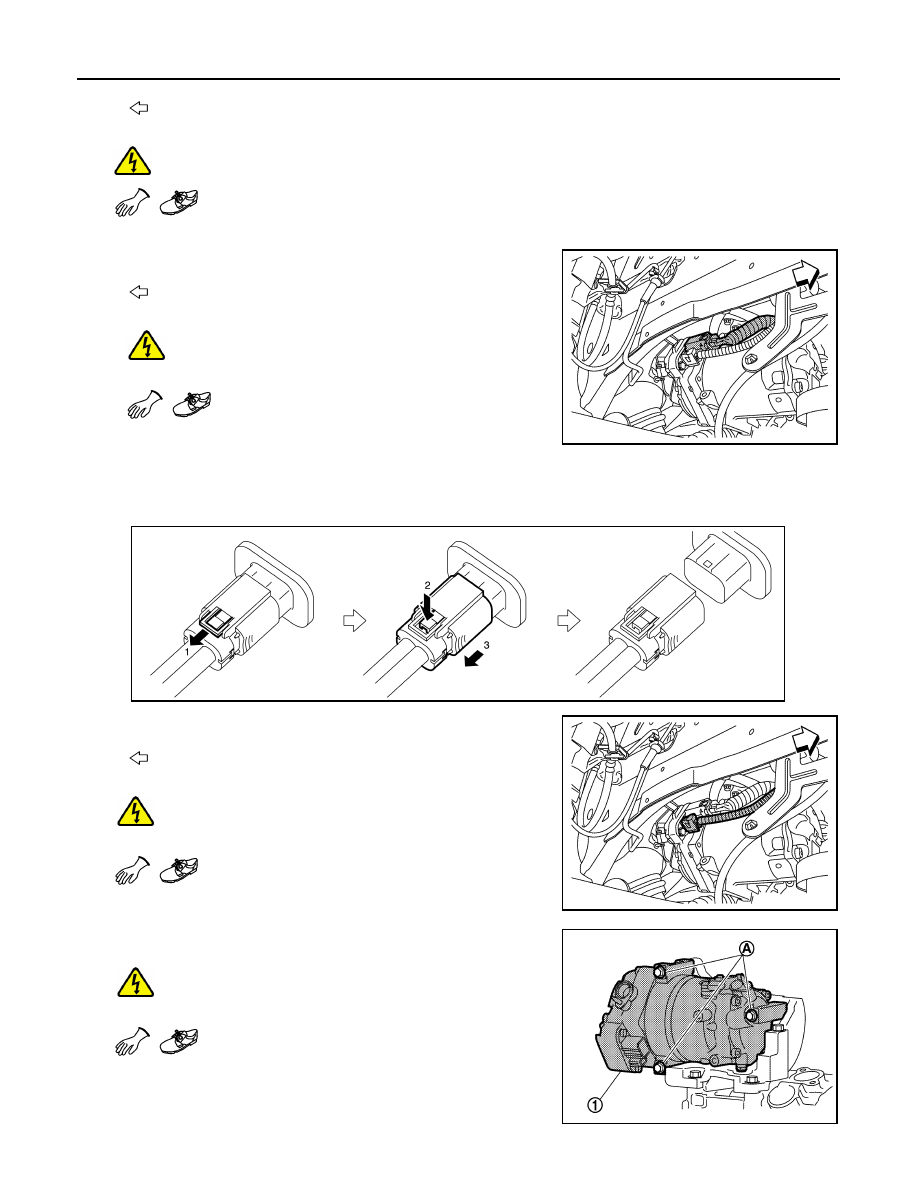

13. Disconnect high voltage harness connector.

WARNING:

•

To prevent electric shock hazards, be sure to wear

protective gear.

• To prevent electric shock hazards, immediately wrap insu-

lating tape around disconnected high voltage connector

terminals.

• Follow the procedure below and disconnect high voltage harness connector.

14. Disconnect low voltage harness connector.

WARNING:

To prevent electric shock hazards, be sure to wear

protective gear.

15. Remove bolts (A) from electric compressor (1).

WARNING:

To prevent electric shock hazards, be sure to wear

protective gear.

: Vehicle front

: Vehicle front

JMIIA2666ZZ

JPCIA0037ZZ

: Vehicle front

JMIIA2667ZZ

JPIIA1766ZZ