Nissan Leaf. Manual - part 531

EVC-148

< DTC/CIRCUIT DIAGNOSIS >

P0A0B HIGH VOLTAGE CONNECTOR INTERLOCK DETECT CIRCUIT

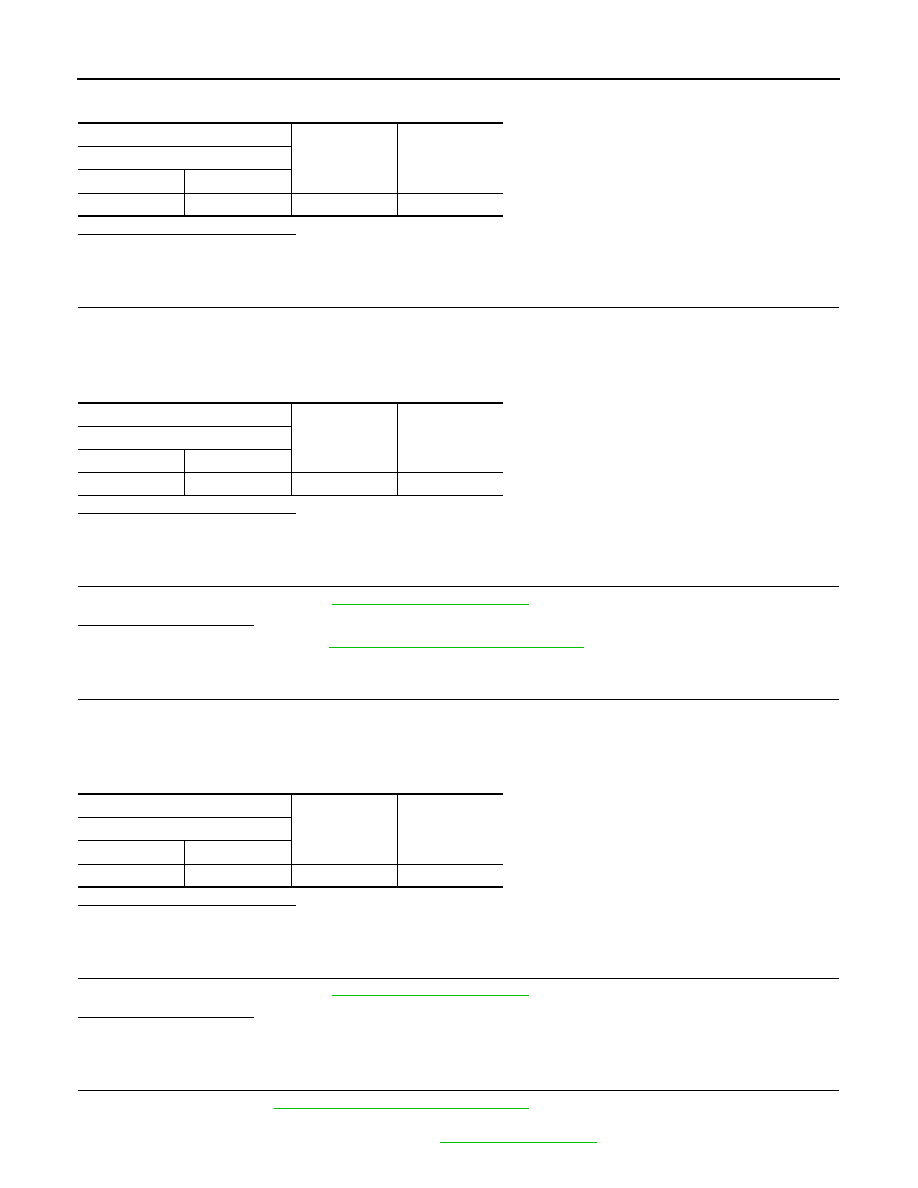

4. Check the voltage between PDM (Power Delivery Module) harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> GO TO 4.

4.

CHECK CONNECTION DETECTING CIRCUIT POWER SUPPLY CIRCUIT

1. Turn power switch OFF.

2. Disconnect VCM harness connector.

3. Check the harness for short to power, between PDM (Power Delivery Module) harness connector and

VCM harness connector.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace error-detected parts.

5.

CHECK INTERMITTENT INCIDENT

Check intermittent incident. Refer to

GI-53, "Intermittent Incident"

.

Inspection result normal?

YES

>> Replace VCM. Refer to

EVC-423, "Removal and Installation"

.

NO

>> Repair or replace error-detected parts.

6.

CHECK CONNECTION DETECTING CIRCUIT SIGNAL CIRCUIT

1. Turn power switch OFF.

2. Disconnect VCM harness connector.

3. Check the harness for short to power, between PDM (Power Delivery Module) harness connector and

VCM harness connector.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Repair or replace error-detected parts.

7.

CHECK INTERMITTENT INCIDENT

Check intermittent incident. Refer to

GI-53, "Intermittent Incident"

.

Inspection result normal?

YES

>> GO TO 8.

NO

>> Repair or replace error-detected parts.

8.

REPLACE VCM

1. Replace VCM. Refer to

EVC-423, "Removal and Installation"

.

2. Reconnect harness connector and parts disconnected.

3. Perform DTC Confirmation Procedure. Refer to

.

+

−

Voltage

PDM (Power Delivery Module)

Connector

Terminal

F23

12

Ground

3 – 7 V

+

−

Voltage

PDM (Power Delivery Module)

Connector

Terminal

F23

12

Ground

0 V

+

−

Voltage

PDM (Power Delivery Module)

Connector

Terminal

F23

15

Ground

0 V