Content .. 1180 1181 1182 1183 ..

Nissan Leaf. Manual - part 1182

PREPARATION

TMS-9

< PREPARATION >

D

E

F

G

H

I

J

K

L

M

A

B

TMS

N

O

P

PREPARATION

PREPARATION

Special Service Tool

INFOID:0000000010120890

The actual shape of the tools may differ from those illustrated here.

Commercial Service Tools

INFOID:0000000010120891

Tool number

(TechMate No.)

Tool name

Description

KV99112300

(J-51050)

Guide pin

Removing and installing traction motor in-

verter

3 pins/set

A: 106 mm (4.17 in) (1 pin) / 96 mm (3.78

in) (2 pins)

JPCIA0332ZZ

Tool name

Description

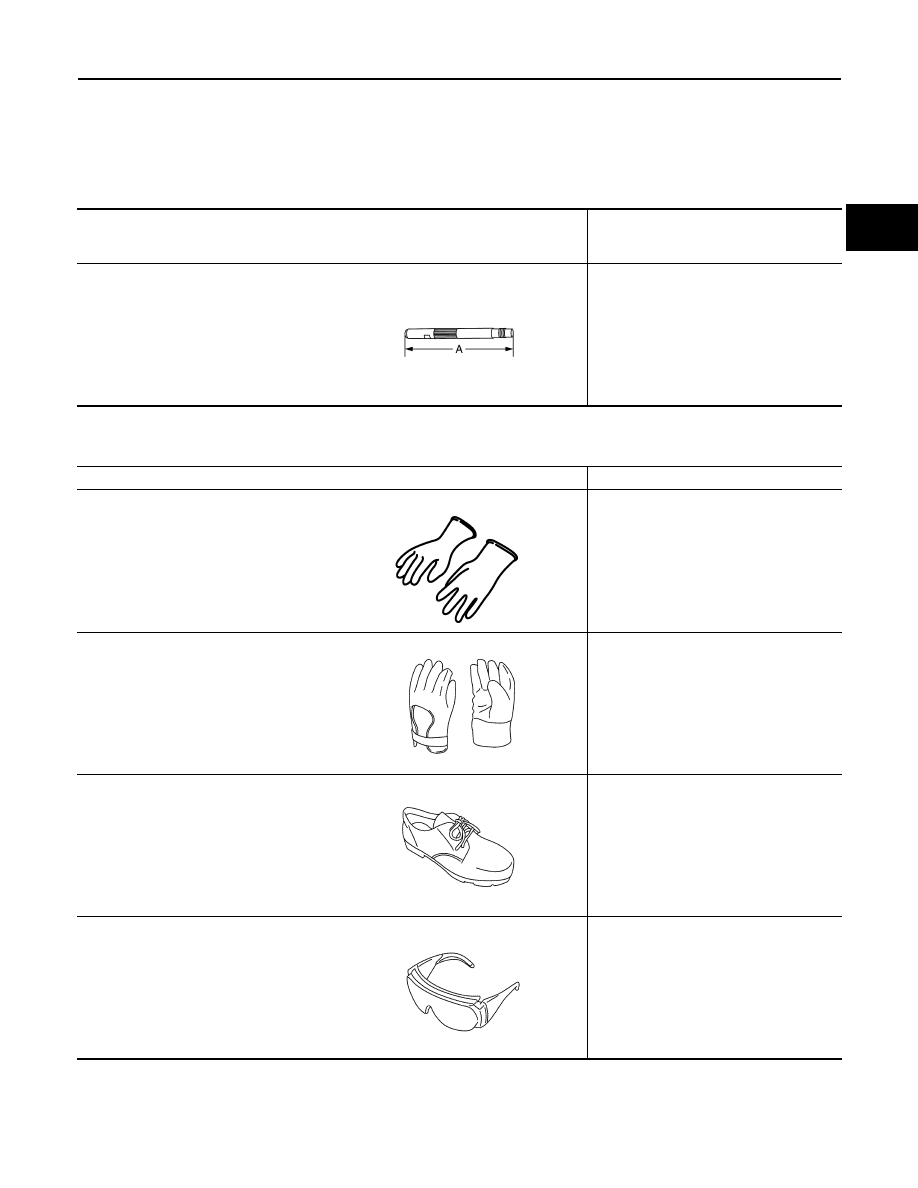

Insulated gloves

Removing and installing high voltage

components

[Guaranteed insulation performance for

1000V/300A]

Leather gloves

• Removing and installing high voltage

components

• Protect insulated gloves

[Use leather gloves that can fasten the

wrist tight]

Insulated safety shoes

Removing and installing high voltage

components

Safety glasses

• Removing and installing high voltage

components

• To protect eye from the spatter on the

work to electric line

[ANSI Z87.1]

JMCIA0149ZZ

JPCIA0066ZZ

JPCIA0011ZZ

JPCIA0012ZZ