Nissan PULSAR N13 Series / ASTRA LD Series. Manual - part 43

Brakes

173

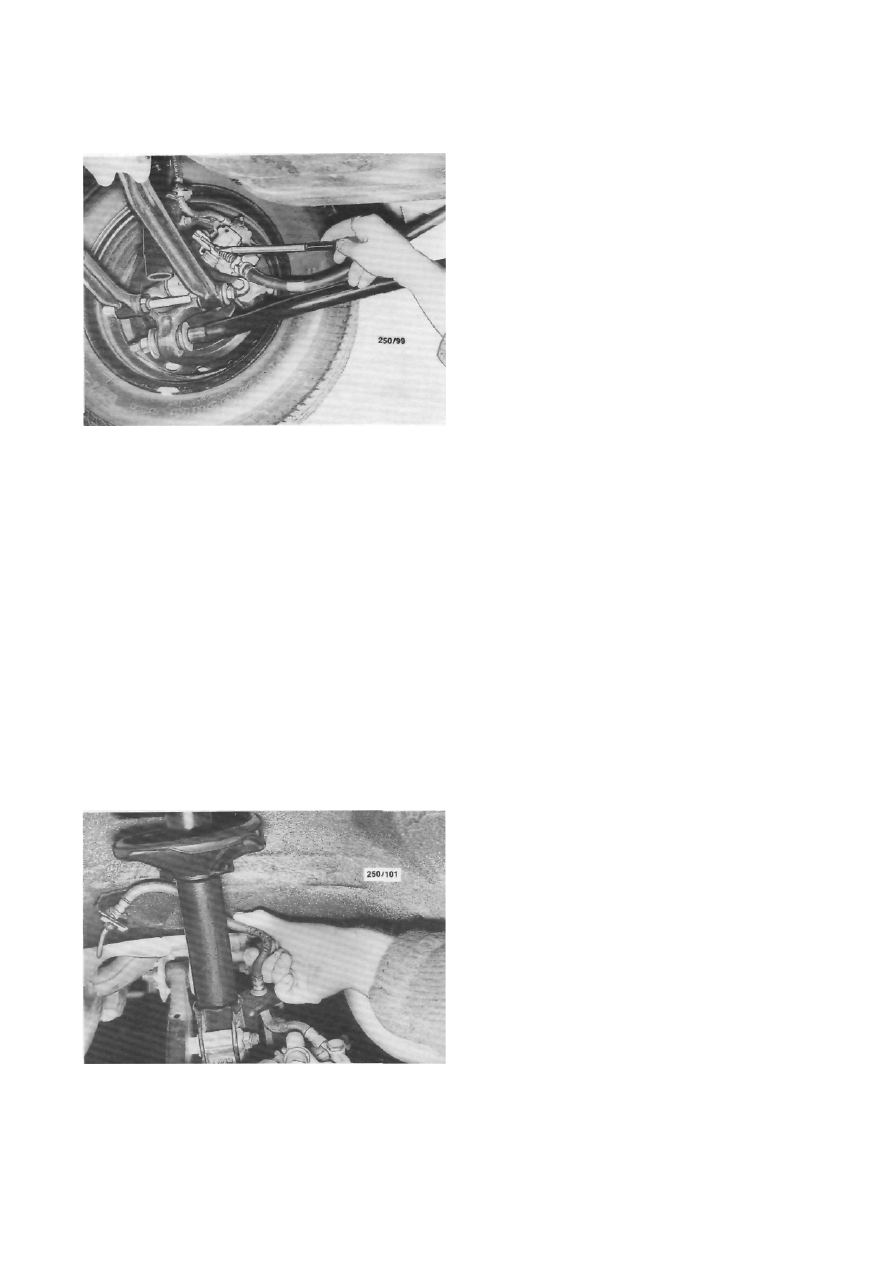

Inspect the handbrake cable for chafing or fraying.

(4) Seized handbrake cables: Renew the hand-

brake cables.

NOTE: Raise the vehicle and spin the

wheels one at a time to check for binding. If

the wheels are not binding, have an assistant

apply and release the brakes. Check if the

brakes release immediately. A clogged mas-

ter cylinder port will cause binding on the

two wheels fed by that particular circuit

from the master cylinder. Open the bleeder

valve on one of the offending wheels to check

if pressure build up is the cause of the

binding. A seized handbrake cable will usu-

ally cause binding on a rear wheel. Discon-

nect the handbrake cable and check if the

wheel will then turn freely.

LOW SPONGY BRAKE PEDAL

(1) Incorrectly adjusted brake shoes: Check and

adjust the brake shoes.

(2) Insufficient fluid in the system: Check for

leaks, replenish the fluid to the specified level and

bleed the hydraulic system.

(3) Air in the brake hydraulic system: Bleed the

hydraulic system.

(4) Master cylinder faulty: Repair or renew as

necessary.

NOTE: A spongy brake pedal in most cases

is caused by air in the hydraulic system. For

air to enter the system one or more of the

sealing rubbers or brake lines must be

sucking in air. Always rectify the cause of

the trouble before bleeding the hydraulic

system. Faulty components usually show up

as fluid leakage.

BRAKES LOCK ON APPLICATION

(1) Gummy linings or brake pads due to oil or

fluid contamination: Renew the linings or brake pads

and rectify the source of contamination.

(2) Scored or eccentric brake drum or warped

disc: Check and machine or renew the drum or disc as

necessary.

(3) Incorrect or distorted linings or disc pads:

Check and renew as necessary.

(4) Brake servo unit faulty: Repair or renew the

brake servo unit.

(5) Broken or stretched brake shoe return

springs: Check and renew the faulty brake springs.

(6) Faulty brake pressure proportioning valve:

Renew the brake pressure proportioning valve.

NOTE: If this condition arises, remove all

the wheels and check the condition of the

friction material for oil contamination and

excessive wear. Check the shoe return

springs for stretching by comparing their

free length with new springs. An eccentric-

brake drum or warped disc will be indicated

by pulsating of the brake pedal when the

brakes are lightly applied.

BRAKE PEDAL PULSATES

(1) Eccentric brake drums or warped disc: Check

and machine or renew the drum or disc as required.

(2) Loose or worn hub bearings: Renew the hub

bearings as necessary.

NOTE: Brake drums or discs that are run-

ning out must be machined. This job is best

entrusted to a brake specialist who will also

be able to determine if a new disc or drum

needs to be installed.

BRAKE FADE

(1) Incorrect shoe adjustment: Check and adjust

the shoe to drum clearance.

(2) Eccentric brake drum: Check and machine or

renew the brake drum.

Check the brake hoses for deterioration, chafing and

leaks.