Nissan Pathfinder (2009 year). Manual - part 503

OIL PUMP

LU-15

< DISASSEMBLY AND ASSEMBLY >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

LU

N

P

O

DISASSEMBLY AND ASSEMBLY

OIL PUMP

Disassembly and Assembly

INFOID:0000000003939438

DISASSEMBLY

1.

Remove oil pump cover.

2.

Remove inner rotor and outer rotor from oil pump body.

3.

Remove the regulator valve plug, regulator valve spring and regulator valve.

INSPECTION AFTER DISASSEMBLY

Clearance of Oil Pump Parts

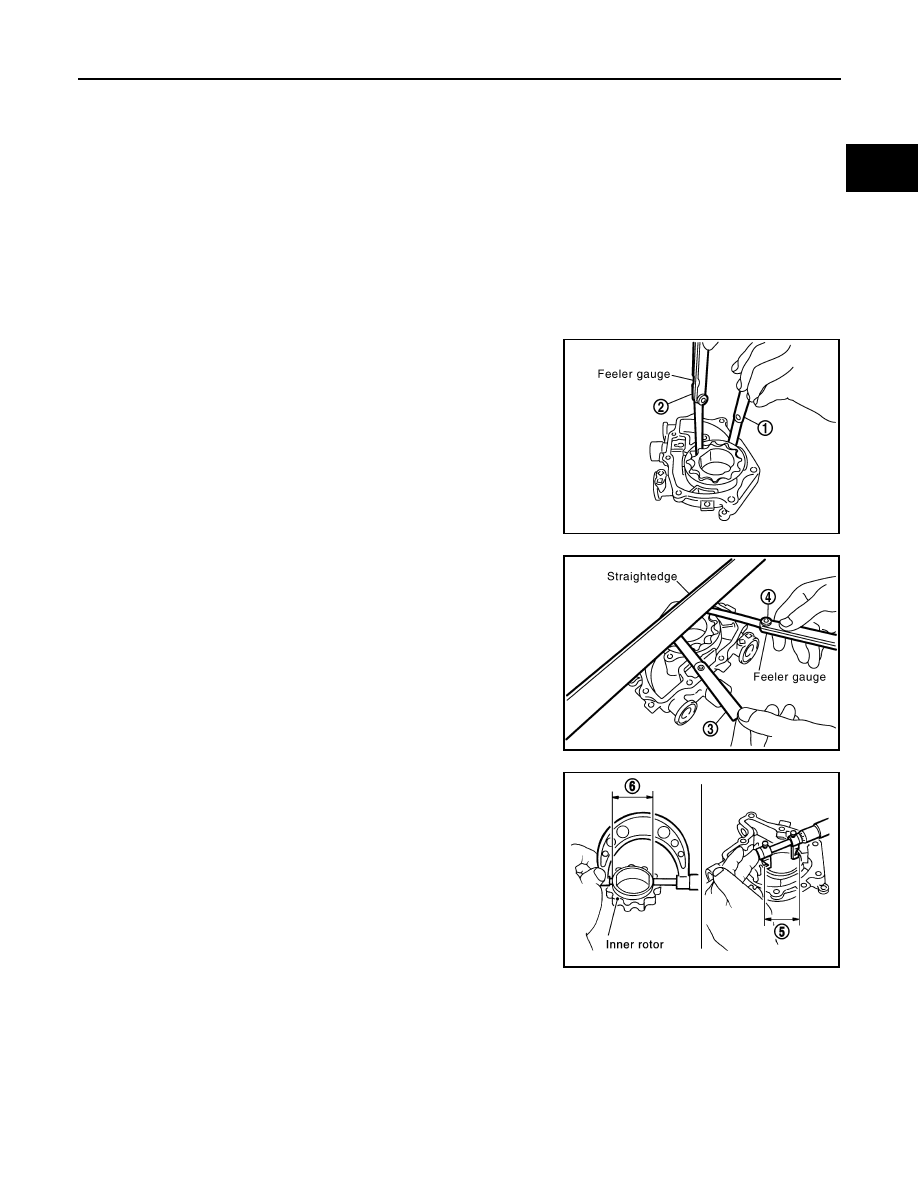

• Measure radial clearance using a suitable tool.

• Measure side clearance using suitable tools.

• Calculate the clearance between inner rotor and oil pump body as

follows.

1.

Measure the inner diameter of oil pump body to brazed portion

(position 5) using suitable tool.

2.

Measure the outer diameter of protruded portion of inner rotor

(position 6) using suitable tool.

3.

Calculate the clearance using the following formula.

• (Clearance) = (Inner diameter of oil pump body) - (Outer diameter of inner rotor)

Regulator Valve Clearance

Body to outer rotor (position 1)

: 0.120 - 0.195 mm (0.0047 - 0.0077 in)

Inner rotor to outer rotor tip (position 2)

: 0.060 - 0.160 mm (0.0024 - 0.0063 in)

PBIC2827E

Body to inner rotor (position 3)

: 0.030 - 0.070 mm (0.0012 - 0.0028 in)

Body to outer rotor (position 4)

: 0.050 - 0.090 mm (0.0020 - 0.0035 in)

PBIC2828E

PBIC0821E

Inner rotor to brazed portion of housing

clearance

: 0.045 - 0.091 mm (0.0018 - 0.0036 in)

2009 Pathfinder