Nissan Pathfinder (2008 year). Manual - part 588

TM-46

< COMPONENT DIAGNOSIS >

DTC P0615 START SIGNAL CIRCUIT

DTC P0615 START SIGNAL CIRCUIT

Description

INFOID:0000000001282766

• TCM prohibits cranking other than at “P” or “N” position.

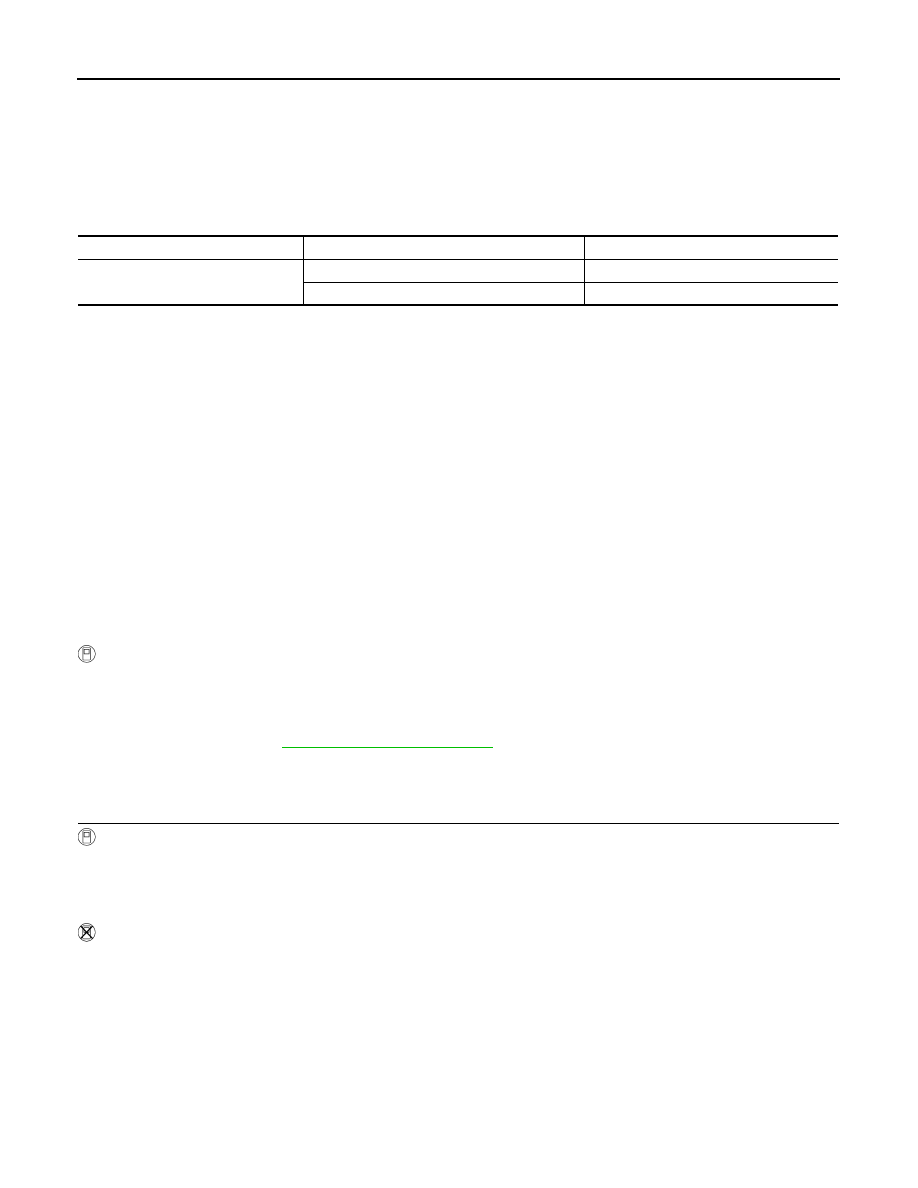

CONSULT-III Reference Value in Data Monitor Mode

INFOID:0000000001282767

On Board Diagnosis Logic

INFOID:0000000001282768

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0615 STARTER RELAY/CIRC” with CONSULT-III or 14th judgement flicker with-

out CONSULT-III is detected when park/neutral (PNP) relay (starter relay) is switched “ON” other than at “P”

or “N” position. (Or when switched “OFF” at “P” or “N” position).

Possible Cause

INFOID:0000000001282769

• Harness or connectors

[The park/neutral position (PNP) relay (starter relay) and TCM circuit is open or shorted.]

• Park/neutral position (PNP) relay (starter relay)

DTC Confirmation Procedure

INFOID:0000000001282770

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1.

Turn ignition switch “ON”. (Do not start engine.)

2.

Select “DATA MONITOR” mode for "TRANSMISSION" with CONSULT-III.

3.

Start engine.

4.

Drive vehicle for at least 2 consecutive seconds.

5.

If DTC is detected, go to

Diagnosis Procedure

INFOID:0000000001282772

1.

CHECK STARTER RELAY

With CONSULT-III

1.

Turn ignition switch ON. (Do not start engine.)

2.

Select “SELECTION FROM MENU” in “DATA MONITOR” mode for "TRANSMISSION" with CONSULT-III

and check monitor “STARTER RELAY” ON/OFF.

Without CONSULT-III

1.

Turn ignition switch ON. (Do not start engine.)

Item name

Condition

Display value

STARTER RELAY

Selector lever in “N”, “P” positions.

ON

Selector lever in other position.

OFF