Nissan Pathfinder (2008 year). Manual - part 485

MA-8

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

(1) If towing a trailer, or using a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every 30,000 miles

(48,000 km) or 24 months.

(2) Refer to “Tire rotation” under the “General maintenance” heading earlier in this section.

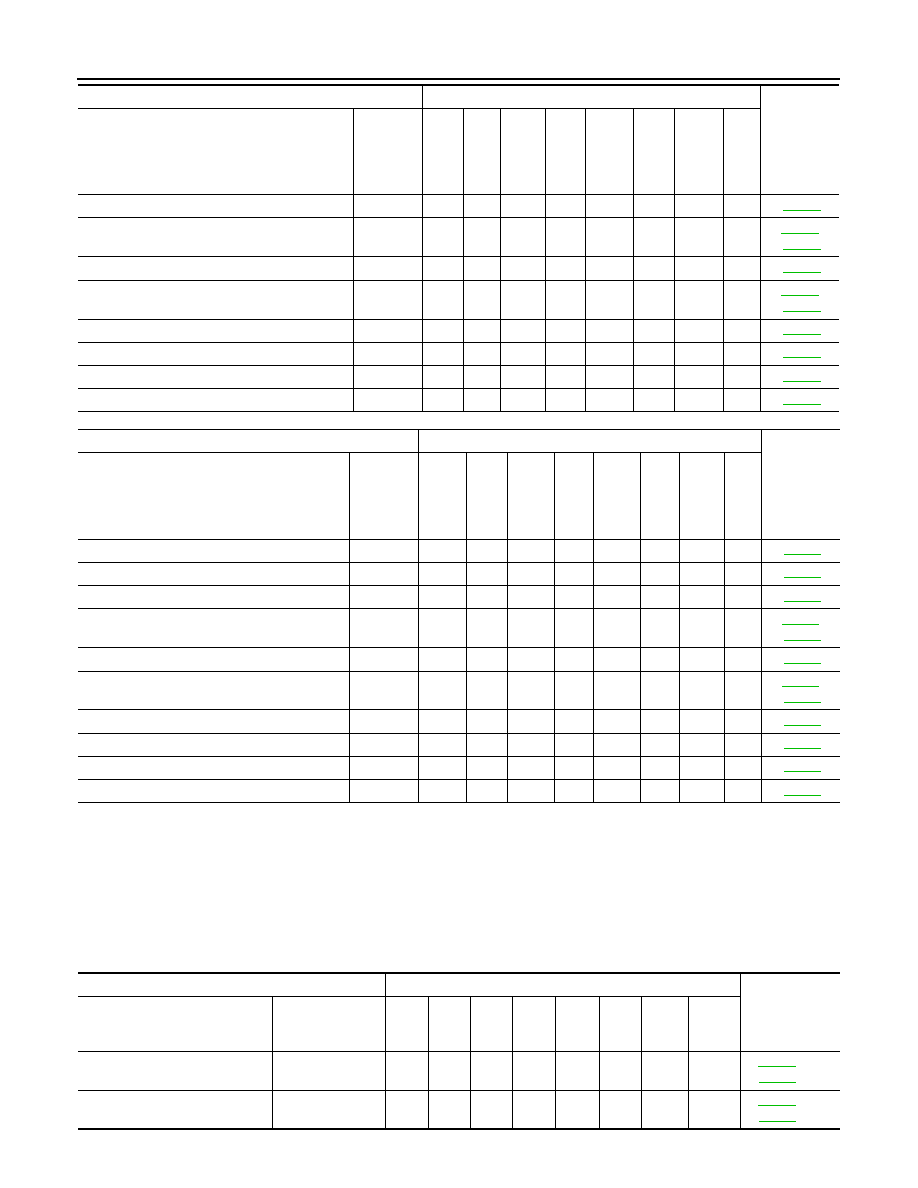

Schedule 2

INFOID:0000000001621703

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace.

I = Inspect. Correct or replace if necessary.

[ ]: At the mileage intervals only

Automatic transmission fluid

NOTE (1)

I

I

Transfer fluid and front final drive oil

NOTE (1)

I

I

Rear final drive oil

NOTE (1)

I

I

Steering gear, linkage, axle, and suspension

parts

I

I

I

I

Tire rotation

NOTE (2)

Drive shaft boots and propeller shaft (4X4)

I

I

I

I

Exhaust system

I

I

I

I

In-cabin microfilter

R

R

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference

Section

- Page

or

- Content

Title

Perform at number of miles, kilometers or

months, whichever comes first.

Miles x

1,000

(km x

1,000)

Months

3.75

(6)

3

7.5

(12)

6

11.25

(18)

9

15

(24)

12

18.75

(30)

15

22.5

(36)

18

26.25

(42)

21

30

(48)

24

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference

Section

- Page

or

- Content

Title

Perform at number of miles, kilometers or

months, whichever comes first.

Miles x

1,000

(km x

1,000)

Months

33.75

(54)

27

37.5

(60)

30

41.25

(66)

33

45

(72)

36

48.75

(78)

39

52.5

(84)

42

56.25

(90)

45

60

(96)

48

Brake lines and cables

I

I

Brake pads and rotors

I

I

I

I

Automatic transmission fluid

NOTE (1)

I

I

Transfer fluid and front final drive oil

NOTE (1)

I

I

,

Rear final drive oil

NOTE (1)

I

I

Steering gear, linkage, axle, and suspension

parts

I

I

I

I

,

Tire Rotation

NOTE (2)

Drive shaft boots and propeller shaft (4X4)

I

I

I

I

Exhaust system

I

I

I

I

In-cabin microfilter

R

R

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference

Section - Page

or - Content Ti-

tle

Perform at number of miles, kilo-

meters or months, whichever

comes first.

Miles x 1,000

(km x 1,000)

Months

7.5

(12)

6

15

(24)

12

22.5

(36)

18

30

(48)

24

37.5

(60)

30

45

(72)

36

52.5

(84)

42

60

(96)

48

Drive belts

NOTE (1)

I*

(VQ)

(VK)

Air cleaner filter

[R]

[R]

(VQ)

(VK)