Nissan Pathfinder (2008 year). Manual - part 424

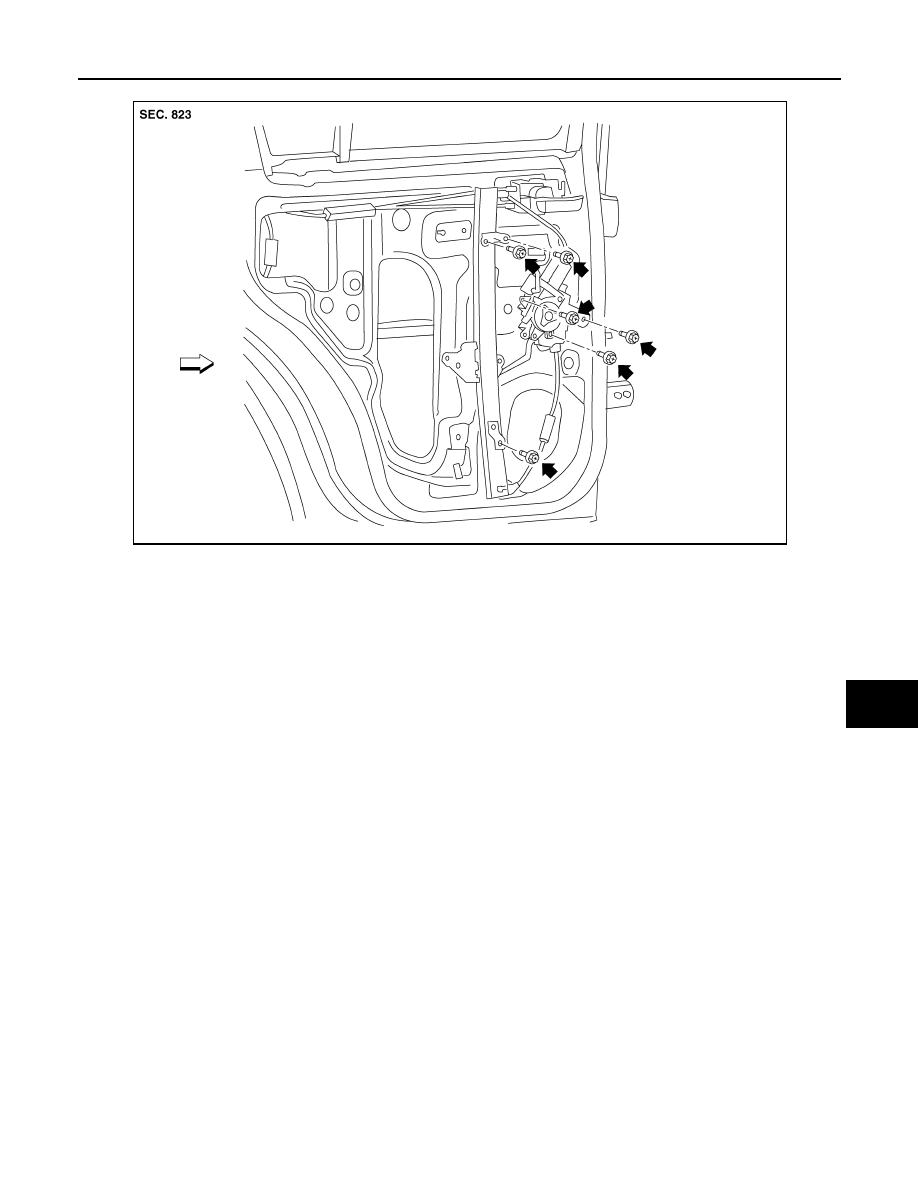

REAR DOOR GLASS AND REGULATOR

GW-19

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

L

M

A

B

GW

N

O

P

• Disconnect the connector from the regulator assembly.

INSPECTION AFTER REMOVAL

Check the regulator assembly for the following items. If a malfunction is detected, replace or grease it.

• Gear wear

• Regulator deformation

• Spring damage

• Grease condition for each sliding part

INSTALLATION

WIIA1034E