Nissan Pathfinder (2008 year). Manual - part 345

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-877

< COMPONENT DIAGNOSIS >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

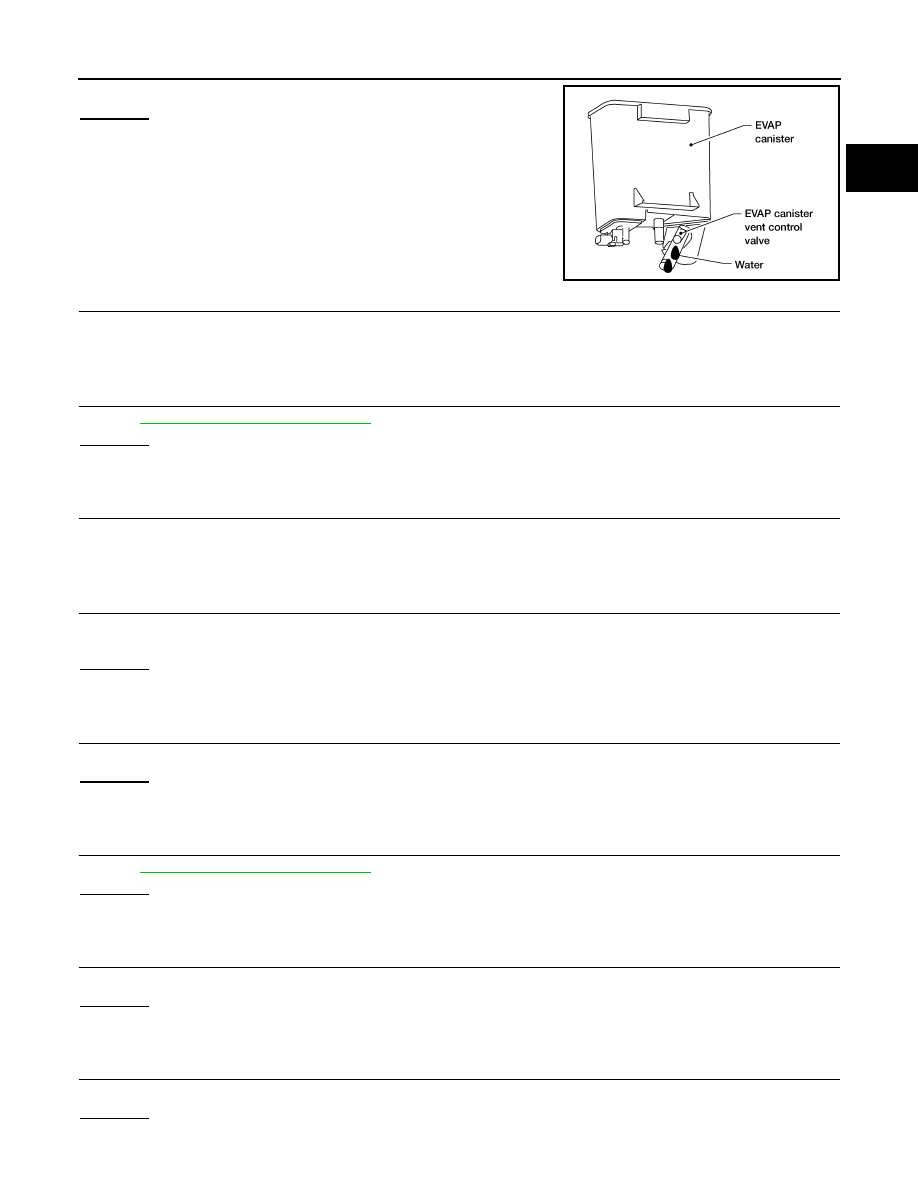

Does water drain from the EVAP canister?

Yes or No

Yes

>> GO TO 3.

No

>> GO TO 6.

3.

REPLACE EVAP CANISTER

Replace EVAP canister with a new one.

>> GO TO 4.

4.

CHECK DRAIN FILTER

EC-878, "Component Inspection"

OK or NG

OK

>> GO TO 5.

NG

>> Replace drain filter.

5.

DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister and drain filter for clogging or poor connection.

>> Repair or replace EVAP hose.

6.

CHECK VENT HOSES AND VENT TUBES

Check hoses and tubes between EVAP canister and refueling EVAP vapor cut valve for clogging, kink, loose-

ness and improper connection.

OK or NG

OK

>> GO TO 7.

NG

>> Repair or replace hoses and tubes.

7.

CHECK FILLER NECK TUBE

Check recirculation line for clogging, dents and cracks.

OK or NG

OK

>> GO TO 8.

NG

>> Replace filler neck tube.

8.

CHECK REFUELING EVAP VAPOR CUT VALVE

EC-878, "Component Inspection"

OK or NG

OK

>> GO TO 9.

NG

>> Replace refueling EVAP vapor cut valve with fuel tank.

9.

CHECK FUEL FILLER TUBE

Check filler neck tube and hose connected to the fuel tank for clogging, dents and cracks.

OK or NG

OK

>> GO TO 10.

NG

>> Replace fuel filler tube.

10.

CHECK ONE-WAY FUEL VALVE-I

Check one-way valve for clogging.

OK or NG

OK

>> GO TO 11.

BBIA0558E