Nissan Pathfinder (2008 year). Manual - part 235

DLN-464

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R230 (4WD)]

REAR FINAL DRIVE

8.

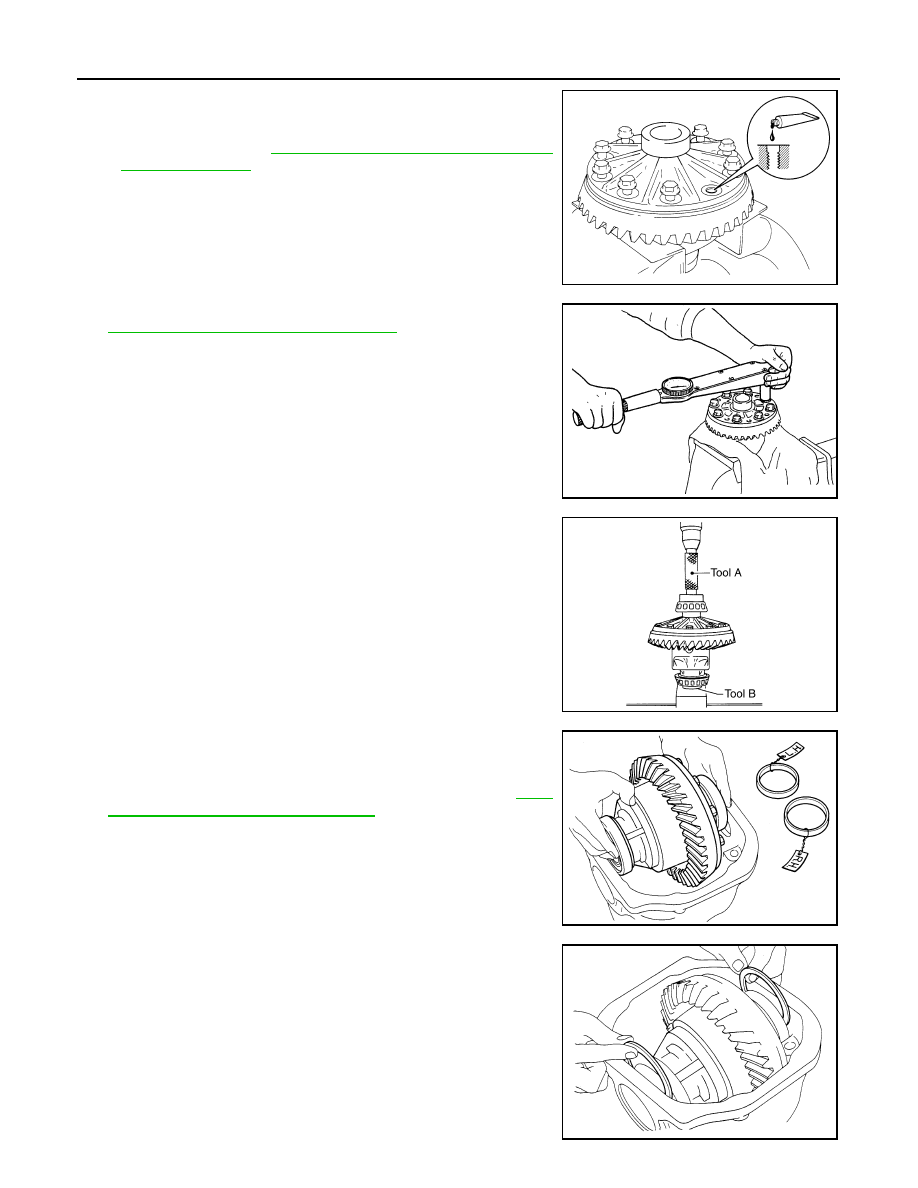

Apply thread locking sealant into the threaded holes of the drive

gear and install the bolts.

• Use Genuine Medium Strength Thread Locking Sealant or

equivalent. Refer to

GI-26, "Recommended Chemical Prod-

CAUTION:

Make sure the drive gear back and threaded holes are

clean.

9.

Tighten the drive gear bolts to the specified torque. Refer to

DLN-450, "Disassembly and Assembly"

. After tightening the

drive gear bolts to the specified torque, tighten an additional 34

°

using Tool.

CAUTION:

• Always use Tool. Avoid tightening based on visual check

alone.

• Tighten drive gear bolts in a crisscross pattern.

10. Press the side bearing inner races into the differential case

using Tools.

CAUTION:

Do not reuse side bearing inner race.

11. Install the differential case assembly with the side bearing outer

races into the gear carrier.

12. Measure the side bearing preload torque. If necessary, select

the appropriate side bearing adjusting washers. Refer to

466, "Inspection and Adjustment"

Torque".

13. Insert the selected left and right side bearing adjusting washers

in place between the side bearings and gear carrier.

SDIA2594E

Tool number

: KV10112100-A (BT-8653-A)

SDIA0247J

Tool number

A: KV38100200 (J-26233)

B: ST33081000 (

—

)

SPD353

SPD919

SPD924