Nissan Pathfinder (2008 year). Manual - part 96

BRC-74

< COMPONENT DIAGNOSIS >

[VDC/TCS/ABS]

C1178, C1181, C1184, C1189 ABS ACTIVE BOOSTER

1.

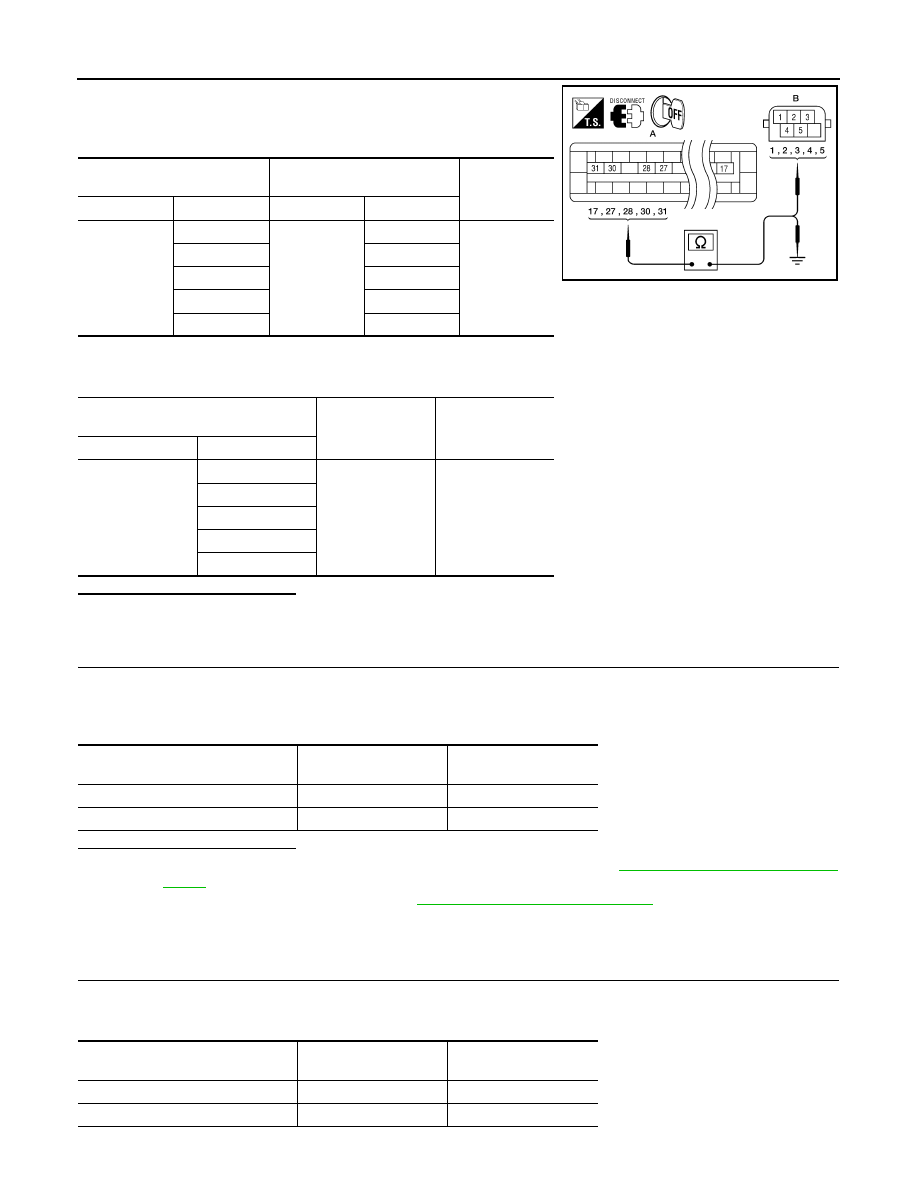

Measure the continuity between ABS actuator and electric unit

(control unit) harness connector E125 (A) and active booster

harness connector E49 (B).

2.

Measure the continuity between ABS actuator and electric unit (control unit) harness connector E125 (A)

and body ground.

Is the inspection result normal?

YES

>> GO TO 3

NO

>> Repair or replace harness or connector.

3.

ACTIVE BOOSTER INSPECTION

1.

Reconnect the active booster and ABS actuator and electric unit (control unit) connectors.

2.

Use “DATA MONITOR” to check if the status of “RELEASE SWITCH NO” and “RELEASE SWITCH NC” is

normal.

Is the inspection result normal?

YES

>> Replace the ABS actuator and electric unit (control unit). Refer to

.

NO

>> Replace the active booster. Refer to

BR-22, "Removal and Installation"

.

Component Inspection

INFOID:0000000001690902

1.

CHECK DATA MONITOR

Use “DATA MONITOR” to check if the status of “RELEASE SWITCH NO” and “RELEASE SWITCH NC” is nor-

mal.

ABS actuator and electric unit

(control unit)

Active booster

Continuity

Connector

Terminal

Connector

Terminal

A: E125

17

B: E49

3

Yes

27

1

28

5

30

2

31

4

ABS actuator and electric unit (control

unit)

—

Continuity

Connector

Terminal

A: E125

17

Ground

No

27

28

30

31

AWFIA0028ZZ

Condition

RELEASE SWITCH NO

(DATA MONITOR)

RELEASE SWITCH NC

(DATA MONITOR)

When brake pedal is depressed.

ON

OFF

When brake pedal is released.

OFF

ON

Condition

RELEASE SWITCH NO

(DATA MONITOR)

RELEASE SWITCH NC

(DATA MONITOR)

When brake pedal is depressed.

ON

OFF

When brake pedal is released.

OFF

ON